Compensation type gas sensor and humiture compensation method thereof

A gas sensor, temperature and humidity compensation technology, applied in the field of gas sensors, can solve the problems of poor measurement accuracy, poor measurement accuracy, false alarms, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

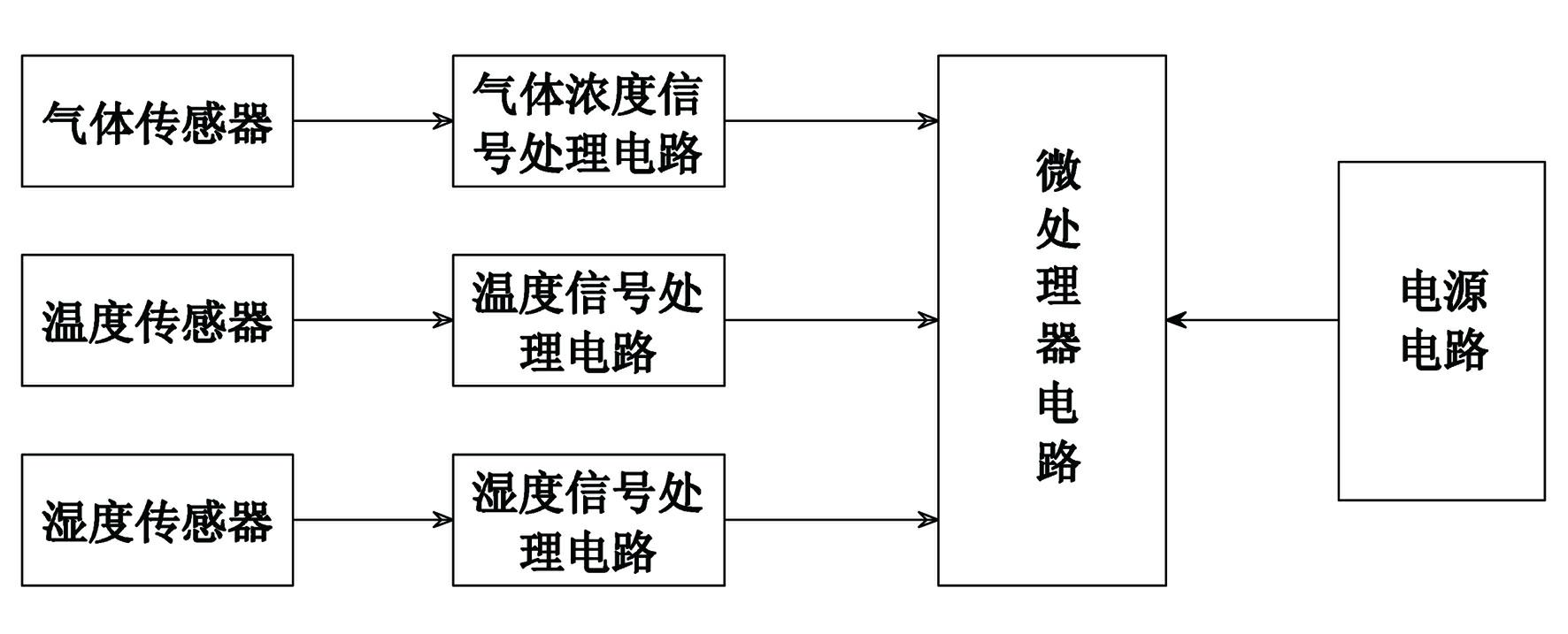

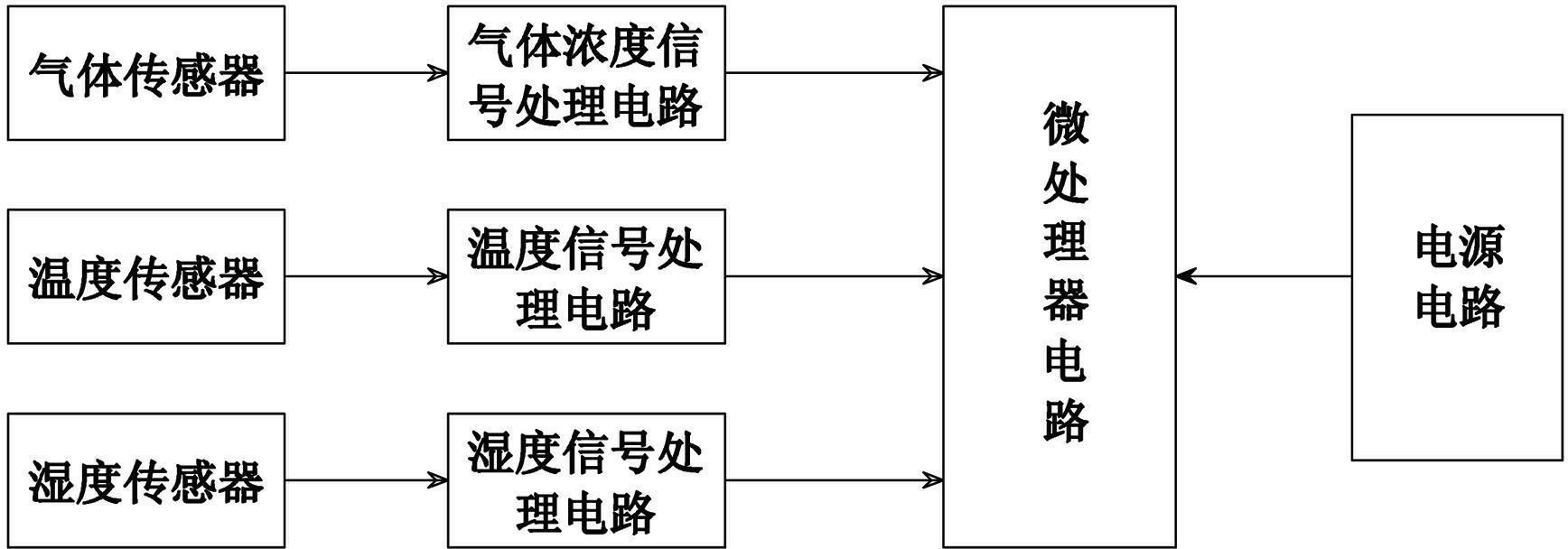

[0028] Such as figure 1 As shown, a compensated gas sensor includes a microprocessor circuit, a gas sensor, a temperature sensor, a humidity sensor, a gas concentration signal processing circuit, a temperature signal processing circuit, a humidity signal processing circuit and a power supply circuit.

[0029] Wherein, the microprocessor circuit includes a microprocessor built-in storage unit pre-stored with a compensation coefficient query database or a microprocessor external memory; the gas concentration signal processing circuit is connected to the gas sensor for measuring the current actual temperature and humidity environment The gas concentration measurement value; the temperature signal processing circuit is connected to the temperature sensor to measure the humidity measurement value under the current actual temperature and humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com