Movable multi-core rubber sleeve cable

A technology of cables and rubber sheaths, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of longer conductors and insulation, smaller bending radius of cables, and bulging conductors, etc., to increase the thickness and flexibility of the sheath Good, enhance the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings.

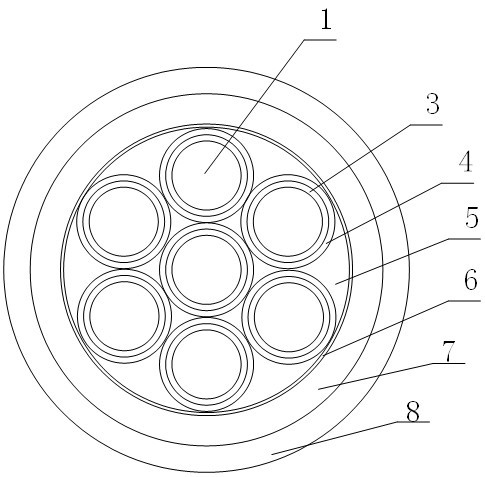

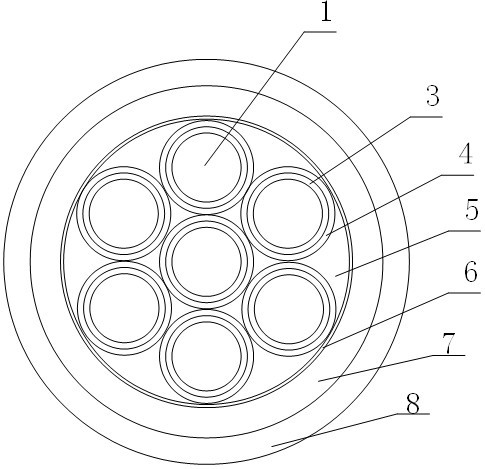

[0012] Such as figure 1 As shown, a multi-core mobile rubber-sheathed cable includes a cable core in the center of the cable, and the cable core is composed of multiple cores and wax wires 6 for binding multiple cores. An inner conductor 1 made of aramid fiber bundles is provided with an isolation layer 3 and an insulating layer 4 is extruded outside the inner conductor. Aramid filament filling 5 is arranged in the gap of the cable core, and the wrapping tape 7 and the extruded outer sheath 8 are sequentially wound outside the cable core; the aramid filament is arranged in the center of the inner conductor. The aramid filament filling is composed of aramid filament and a rubber layer extruded outside the aramid filament.

[0013] When assembling, first combine a plurality of aramid filaments and wire bundles into an inner conductor 1; then extrude an insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com