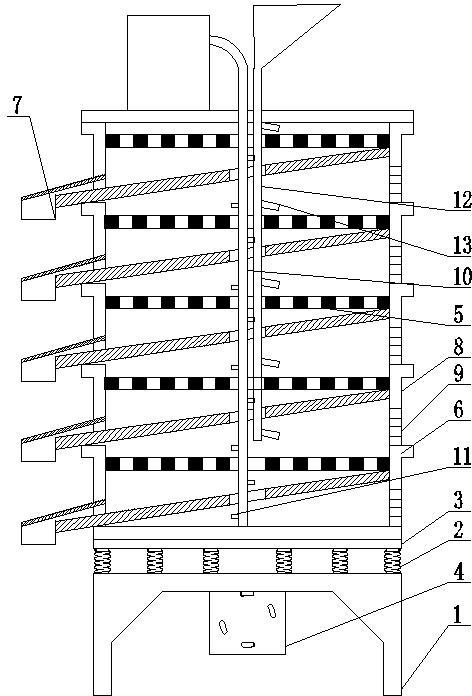

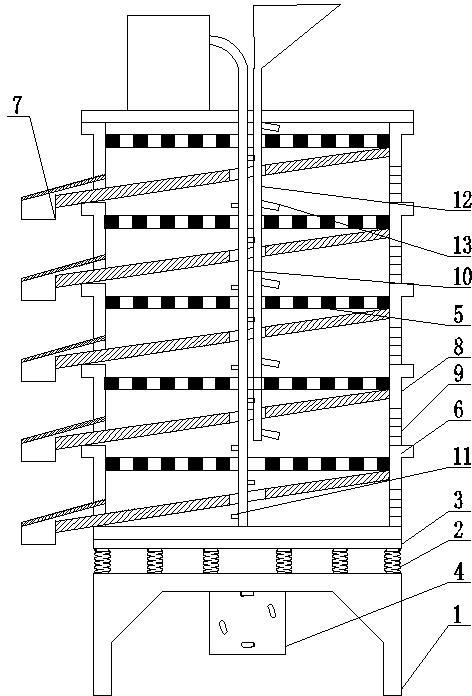

Sieving and drying integrated machine

An all-in-one, drying technology, applied in dryers, sieves, drying and other directions, can solve problems such as large plant and equipment investment, increase in the number of operators, and prone to agglomeration, saving operating costs and occupying workshops. Less, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] as attached figure 1 Shown: the screening and drying all-in-one machine of the present invention includes a support 1, the support is connected to the vibration excitation plate 3 through a group of springs 2, and the vibration excitation motor seat frame 4 is connected to the bottom of the vibration excitation plate. A sieve group is installed on the excitation plate, and the sieve group is formed by sequentially connecting 2-30 layers of sieves through connecting flanges 6. The bottom of each layer of the sieve is connected to the discharge hopper 7, and the sieve group is connected to the hot air supply. Air pipes and feed pipes.

Embodiment 2

[0020] In the screening and drying integrated machine, the sieve includes a sieve plate 5, the periphery of the sieve plate is connected with a support plate 8, and the support plate is externally connected with the connecting flange, and the support plate is There is a group of ventilation holes 9.

Embodiment 3

[0022] In the screening and drying integrated machine, the air supply pipeline includes an air supply main pipe 10, and the air supply main pipe is connected to a group of air supply branches 11.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap