High-speed straightening dimensioning blanking process and equipment for aluminum flat pipe of automobile air conditioner

A technology for automotive air conditioners and aluminum flat tubes, applied in the field of high-speed straightening and fixed-length blanking technology and equipment for aluminum flat tubes for automotive air conditioners, which can solve the problems of low blanking accuracy and slow running speed, and achieve consistent errors in blanking Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

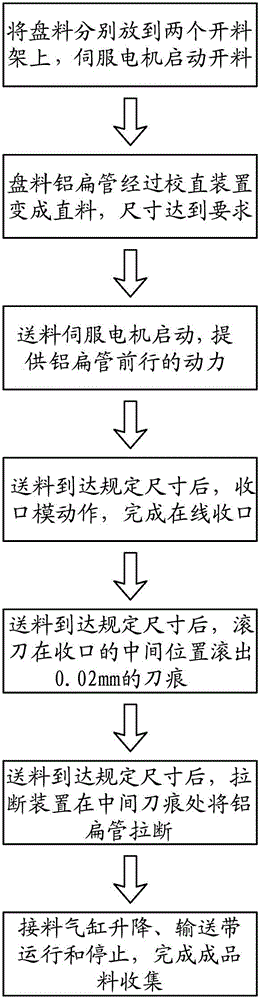

[0033] Such as figure 1 Shown in, according to the automobile air-conditioning aluminum flat tube high-speed straightening fixed length blanking process of the present invention can comprise the following steps:

[0034] (1) Put the aluminum flat tube coils on the two sets of cutting racks respectively, and start the cutting servo motor to cut the materials;

[0035] (2) After the aluminum flat tube coil passes through the straightening device, it becomes a straight aluminum flat tube material, and the straightness meets the requirements;

[0036] (3) Start the feeding servo motor to provide forward power for the aluminum flat tube straight material;

[0037] (4) After the feeding length reaches the specified size, the closing mold moves to complete the online closing;

[0038] (5) After the feeding length reaches the specified size, the hob rolls out a 0.02mm knife mark in the middle of the closing position;

[0039] (6) After the feeding length reaches the specified size,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com