Processing process of titanium alloy ring groove rivet with big length-to-diameter ratio

A technology of ring groove rivets and large aspect ratio, which is applied to the processing technology of titanium alloy ring groove rivets with large aspect ratio and the processing technology field of ring groove rivets, can solve the hidden dangers of product quality control and safe use, and the difficulty of surface roughness. Guarantee, poor product dimensional consistency and other problems, to achieve the effect of reducing workpiece runout, shortening processing time, and high accuracy of outer circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

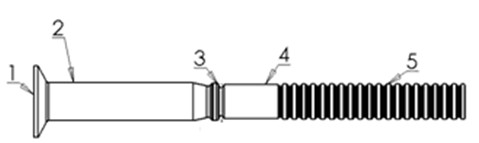

[0023] The specific embodiments of the present invention are given below with reference to the accompanying drawings, which are used to further describe the constitution of the present invention.

[0024] Processing technology reference of titanium alloy ring groove rivets with large length-to-diameter ratio in this embodiment figure 1 , first grind the blank to make the diameter of the blank consistent, and then use the supporting chuck to clamp the blank to the lathe processing equipment (that is, the center type CNC lathe), first process the process ring groove, and then Carry out the processing of the broken neck groove, and then process the working rod, and finally cut off according to the size to obtain the overall size of the head.

[0025] The working steps are described as follows:

[0026] 1. Clamping one end of the head of the blank in 1 direction, use the outer circle rough turning tool to flatten the outer circle and the end face of the other end, the spindle spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com