Concrete wet type injection system

A wet spraying and concrete technology, which is applied in the field of mining machinery, can solve the problems of discontinuous feeding and mixing, low degree of automation, and low spraying efficiency, and achieve the effects of compact structure, reasonable layout, and improved quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

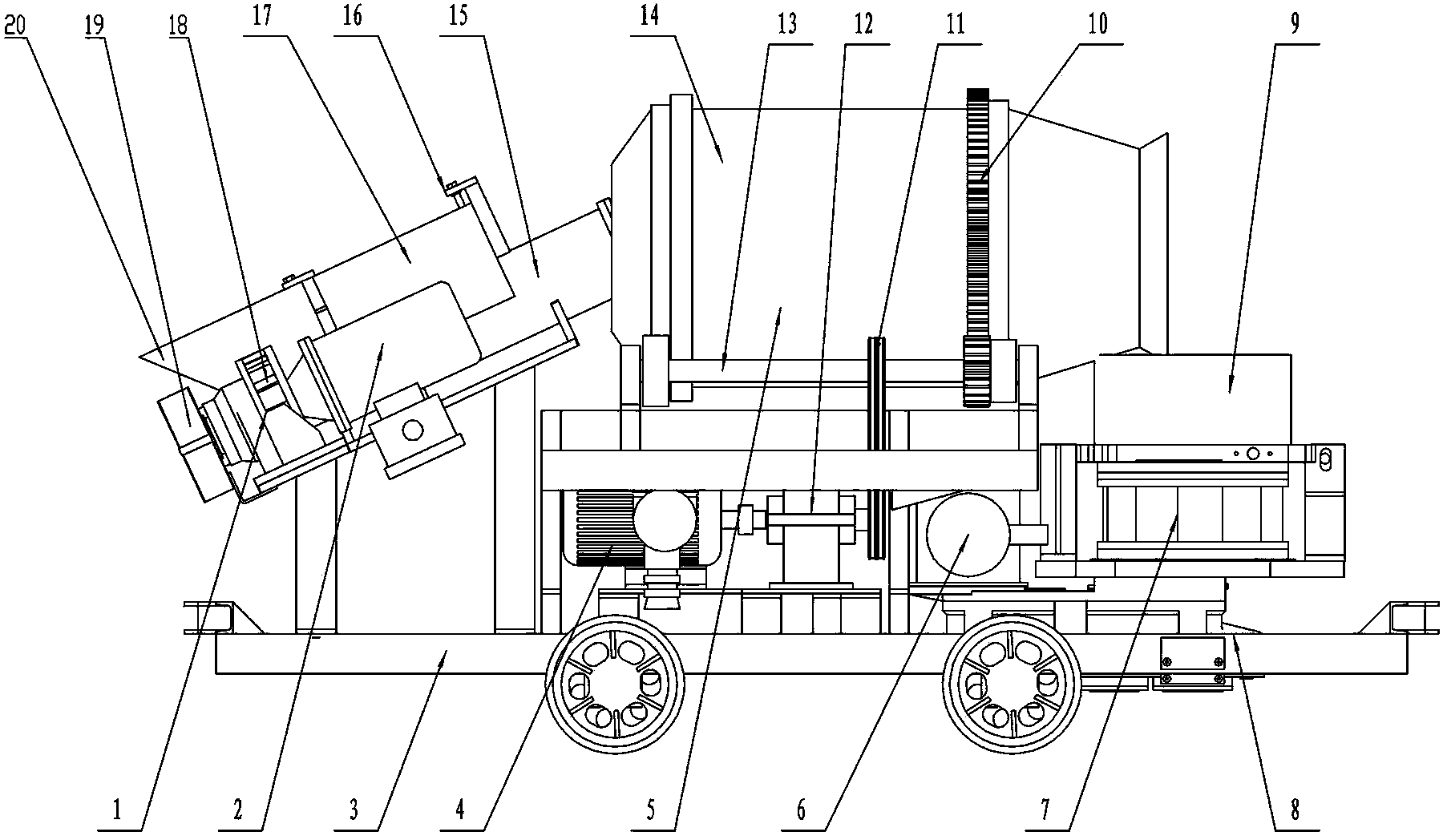

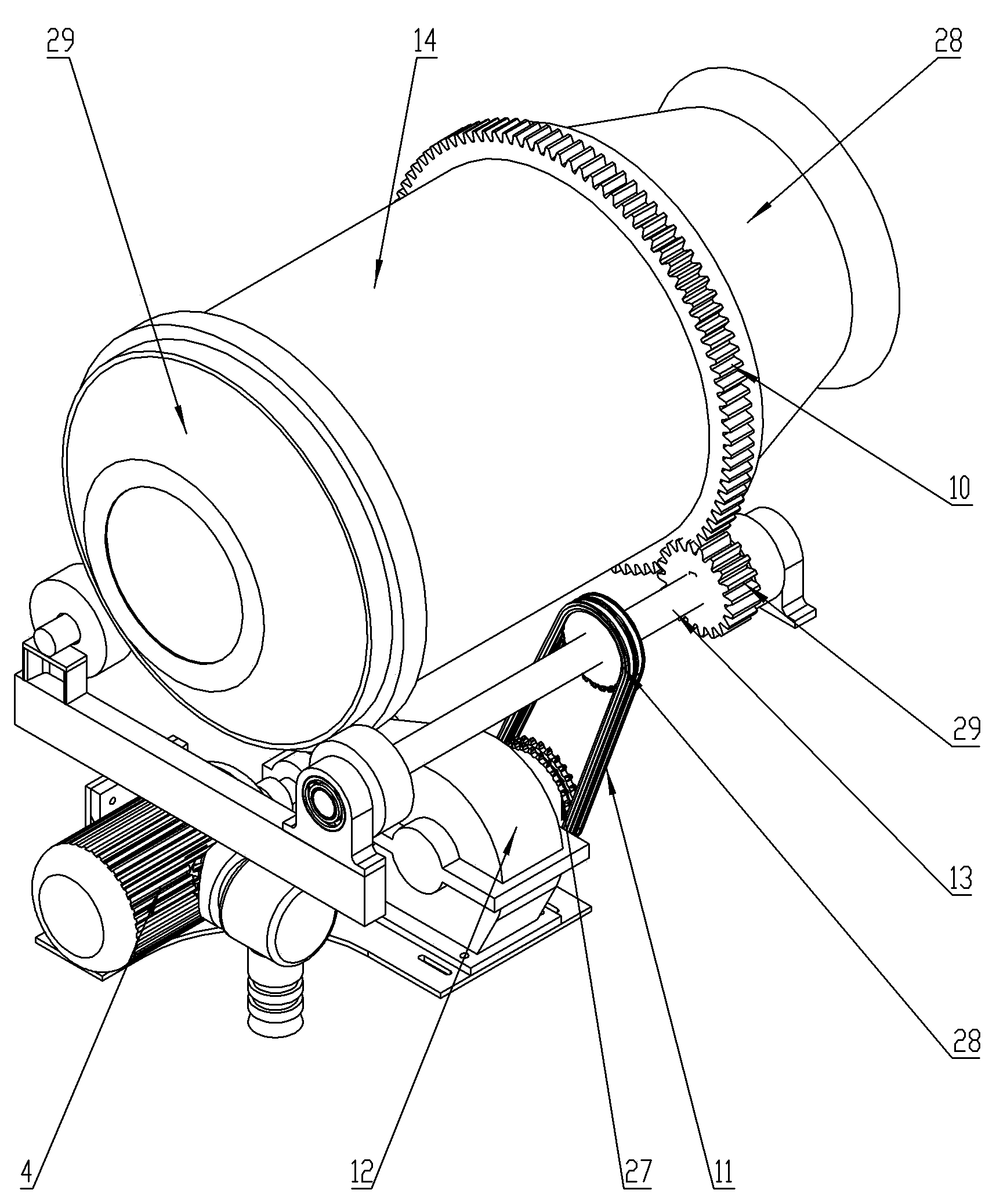

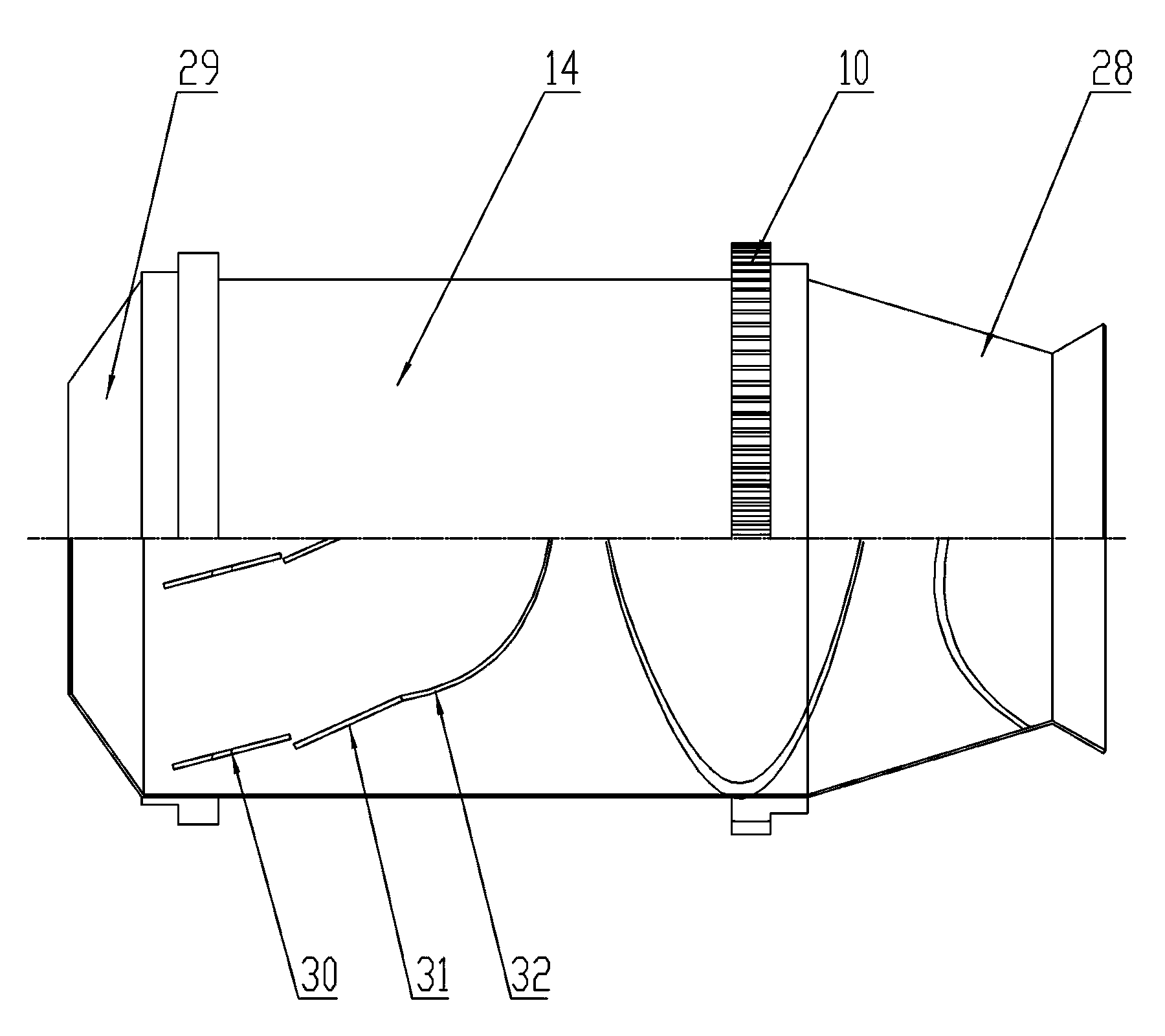

[0028] Embodiment 1 A kind of concrete wet injection system, such as figure 1 As shown, the feeding machine 1, the mixer 5 and the wet spraying machine 7 are sequentially connected to the frame 3 according to the process flow. The feeder 1 is arranged at the front end of the frame 3, and its motor 2 drives the screw shaft 21 to rotate through the reducer 18 and the transmission gear 19. A sand hopper 17 and a cement hopper 20 are respectively arranged above the screw cylinder 15. The feeding ports of the hopper 17 and the cement hopper 20 are respectively provided with adjusting devices 16 that can adjust the amount of feed, and the top of the screw cylinder 15 goes deep into the mixing drum 14, and an arc-shaped cutout 34 is formed below it; the mixer 5 The electric motor 4 and the reducer 12 are arranged under the mixing drum 14, the reducer 12 is connected with the main shaft 13 through the double row chain 11, the main shaft 13 drives the ring gear 10 and the mixing drum 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com