Metal plate embossing technology and corresponding metal plate embossing machine

A metal plate and embossing machine technology, applied in decorative art, embossed decorative parts, etc., can solve the problems of low production efficiency and good product rate, non-environmental protection, poor product aesthetics, etc., to improve production efficiency and good product rate, Good aesthetics and good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

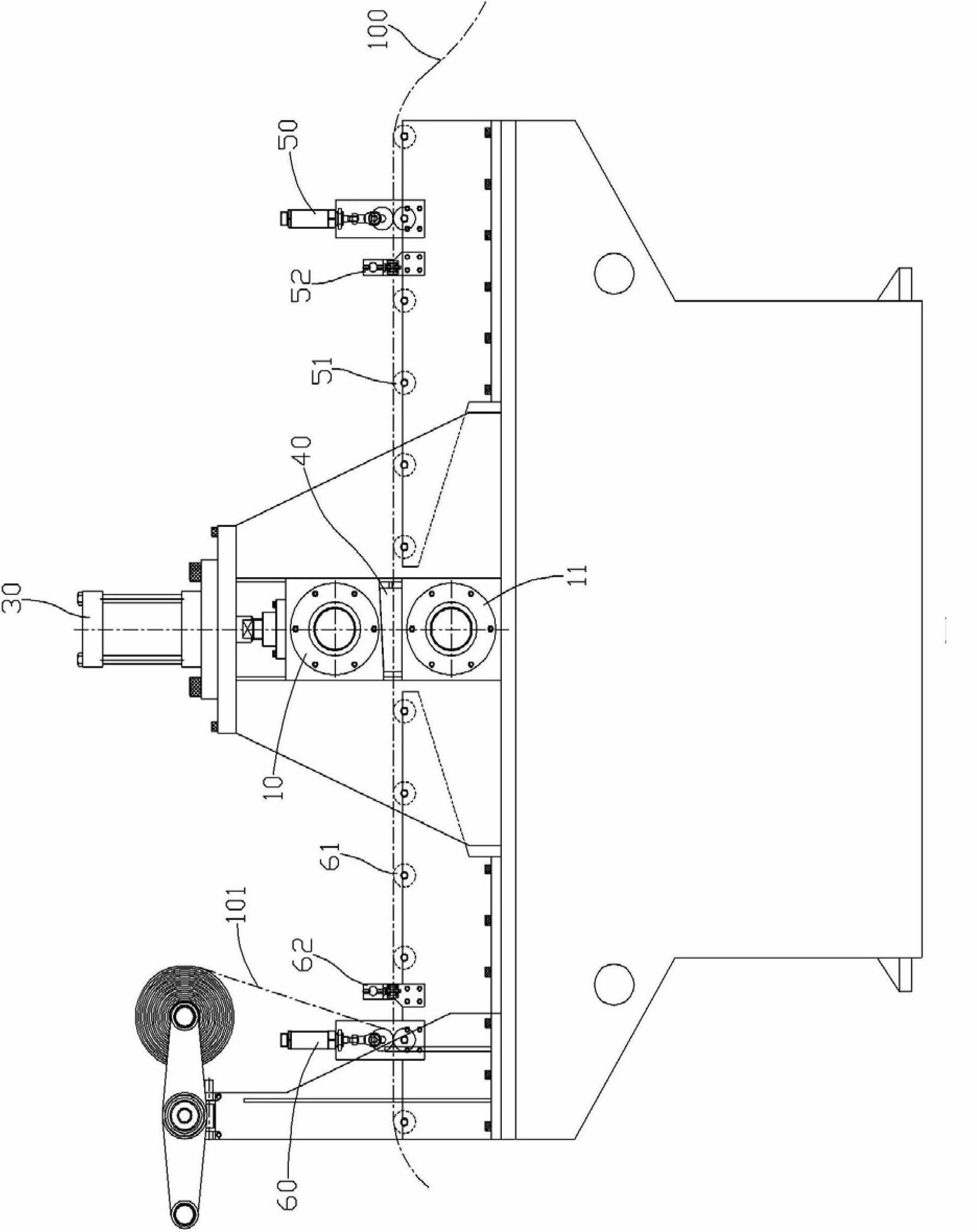

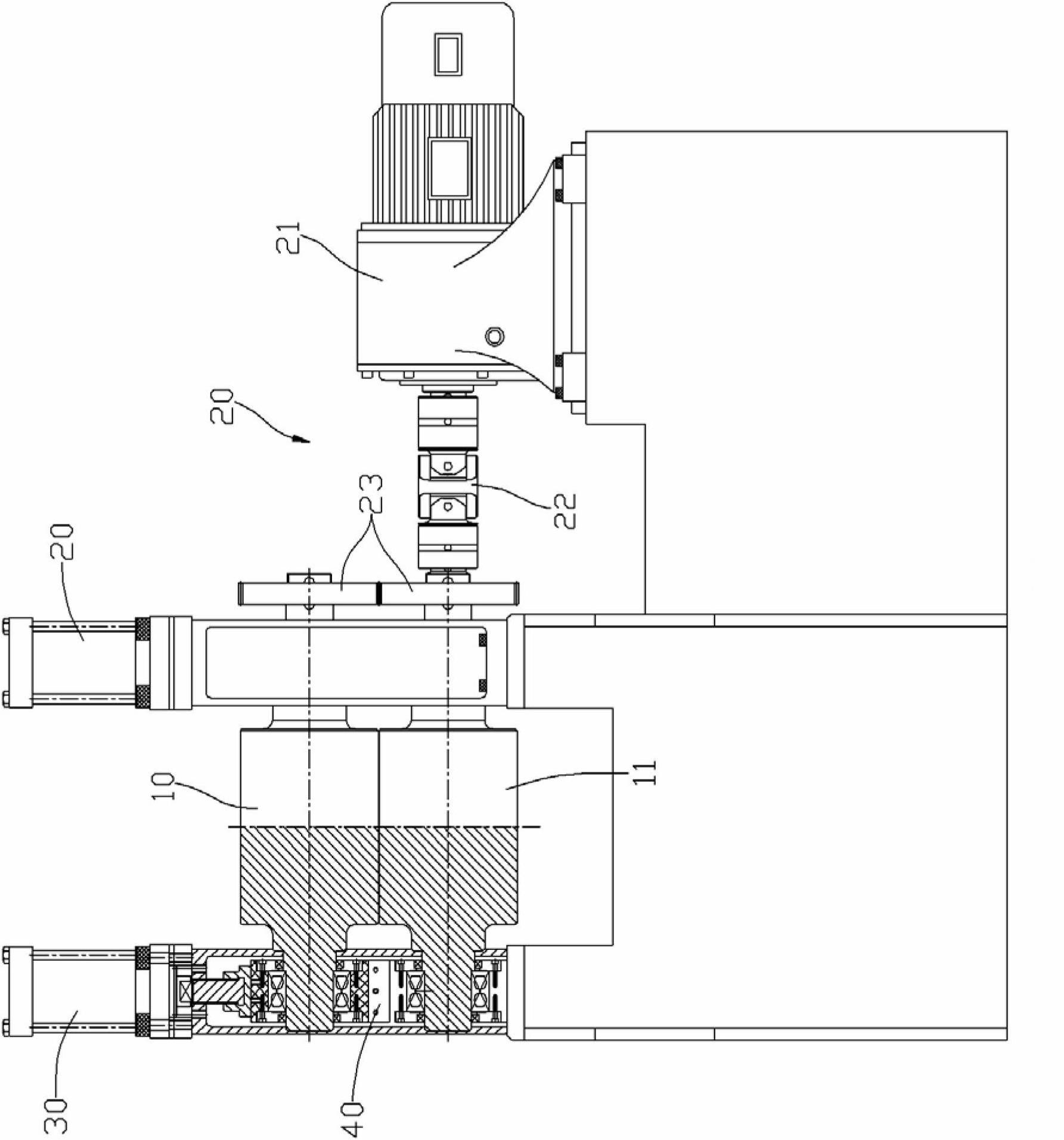

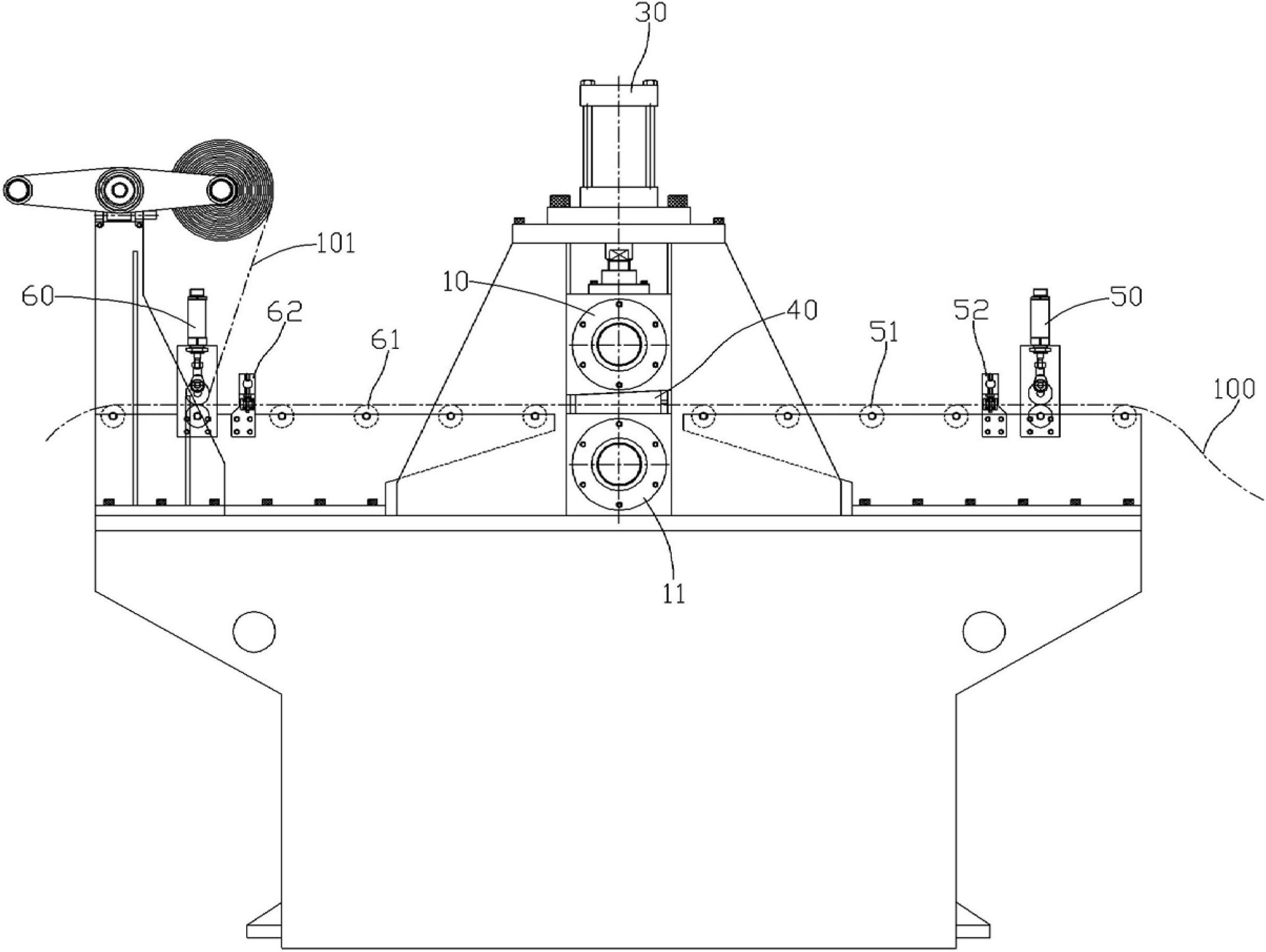

[0021] The metal plate embossing process of the present invention guides the metal plate between the precision laser embossing roller driven by the transmission device and the smooth roller through the feeding group and the first guide wheel group, and the embossing roller and the smooth roller pass through The hydraulic cylinder is pressed tightly. When the metal plate passes between the embossing roller and the smooth roller, the embossing roller will press the pattern on the surface of the metal plate. The metal plate after the pattern is pasted by the film group, and then passed through the second The guide wheel set is exported.

[0022] See attached figure 1 And attached figure 2 As shown: the metal plate embossing machine of the present invention has a set of precision laser embossing rollers 10 and smooth rollers 11 driven by a transmission device 20, wherein the transmission device 20 includes a reducer 21, a universal coupling 22, And a pair of synchronous gears 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com