Maglev Elevator Guide System and Its Control Method

A guiding system and magnetic levitation technology, applied in elevators, transportation and packaging, etc., can solve the problems of poor accuracy and stability, large power loss, etc., and achieve the effect of eliminating friction, reducing energy consumption, and reducing the accuracy of guide rails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

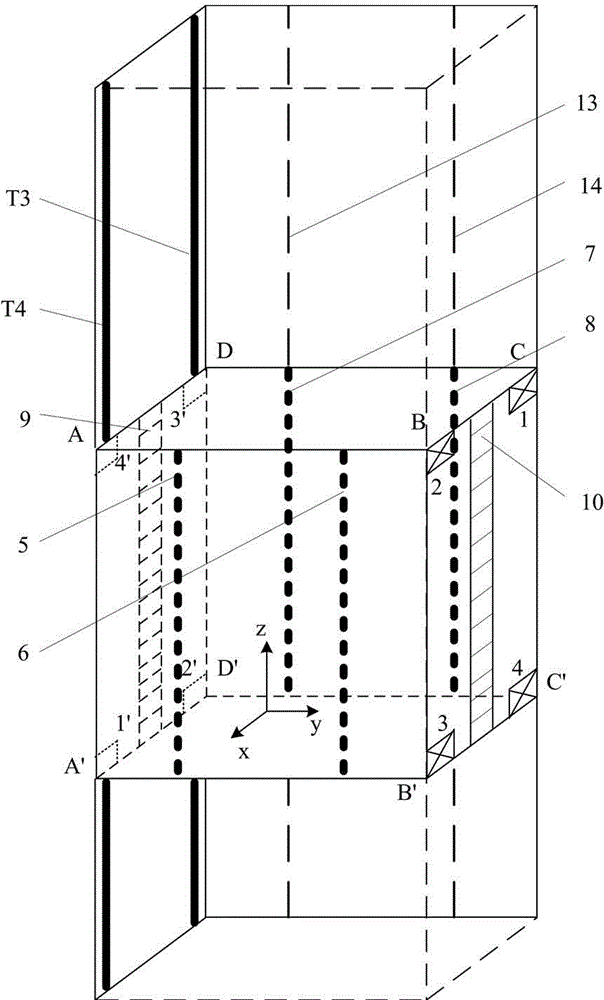

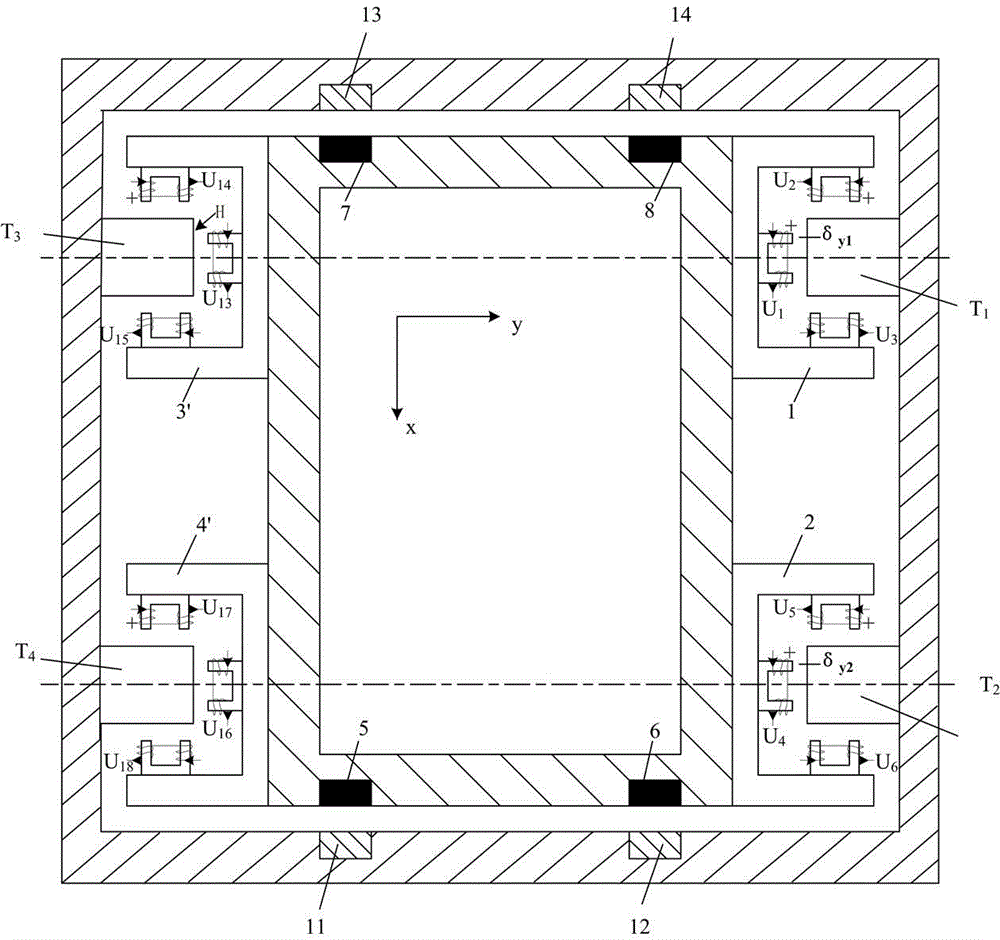

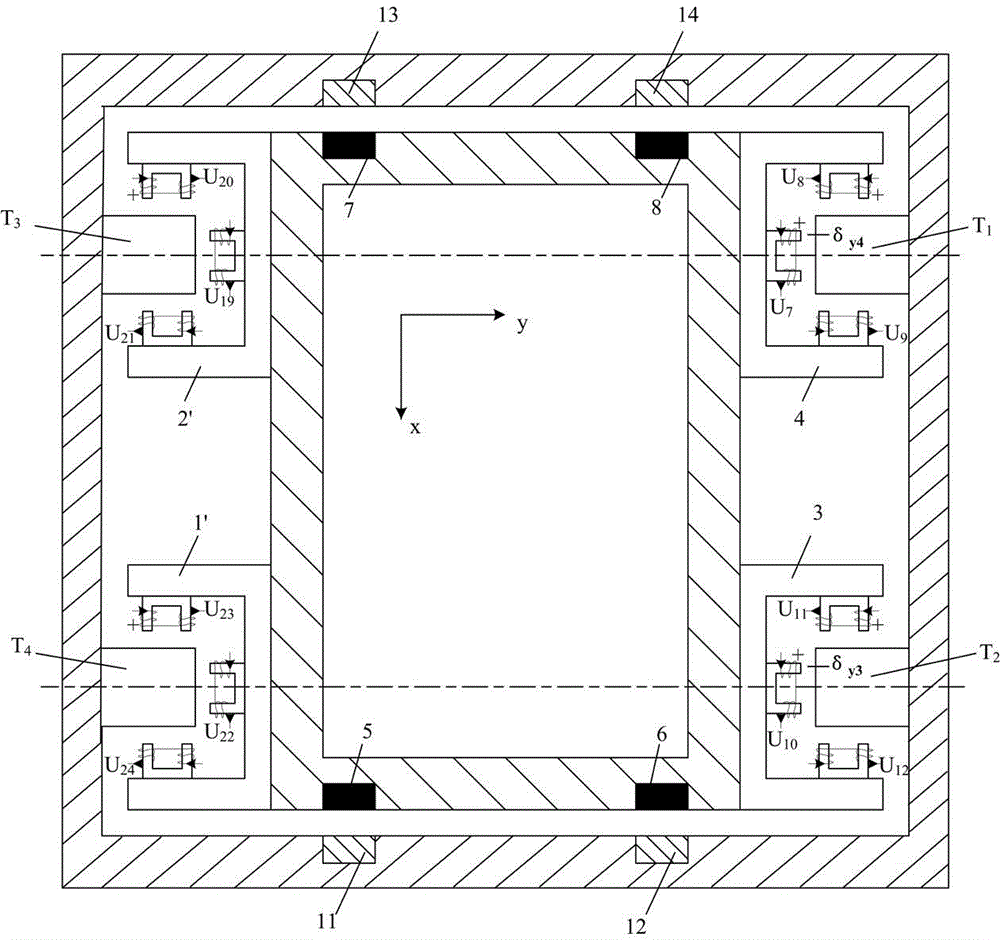

[0035] Implementation method: Below in conjunction with accompanying drawing, the present invention is further described:

[0036] Such as figure 1 and 4 As shown, the present invention provides a magnetic levitation elevator guide system, including an elevator car and an elevator shaft, and a guide device is arranged on the left and right side walls of the elevator shaft, the guide device is a single electromagnetic guide device, and the guide device includes a The guide rail on the elevator shaft wall and the U-shaped guide shoe 111 arranged on the outer wall of the elevator car, the U-shaped guide shoe corresponds to the guide rail, and the guide rail is a T-shaped magnetic guide rail; the three inner walls of the U-shaped guide shoe are also provided with The U-shaped electromagnetic force device corresponds to the guide rail and maintains a gap with the guide rail; the U-shaped electromagnetic force device is a U-shaped iron core wound with an electromagnetic coil.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com