Clay gun plugging machine of smelting furnace for oxygen-enriched smelting

A mud cannon and melting pool technology, applied to blast furnace components, furnaces, blast furnace details, etc., can solve problems such as difficult installation, complicated mechanism, troublesome operation, etc., and achieve accurate gun action, simple overall structure, and convenient adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

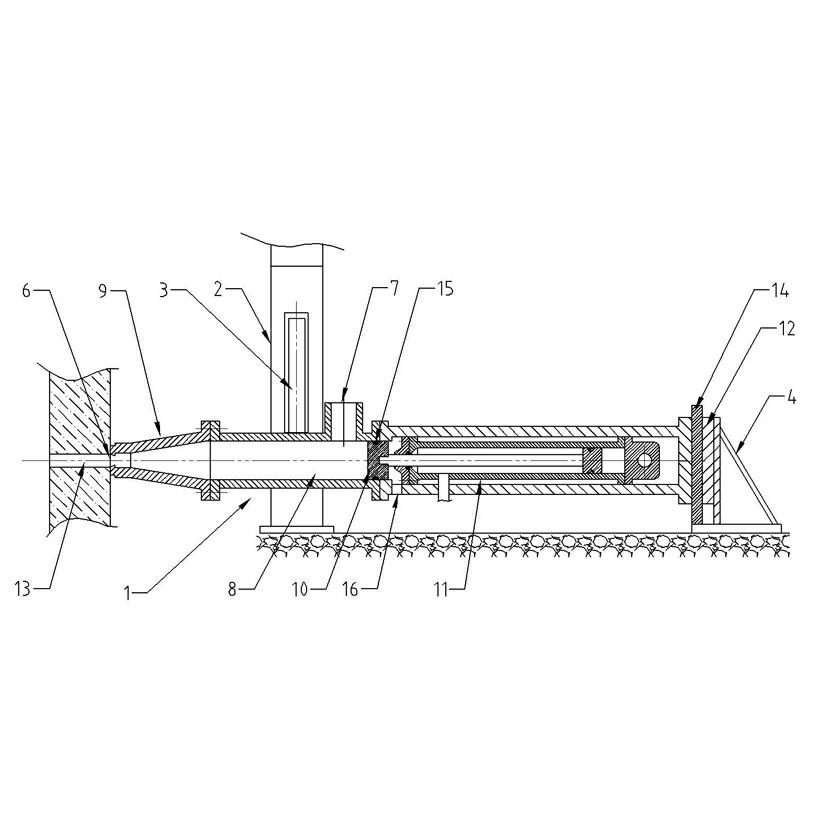

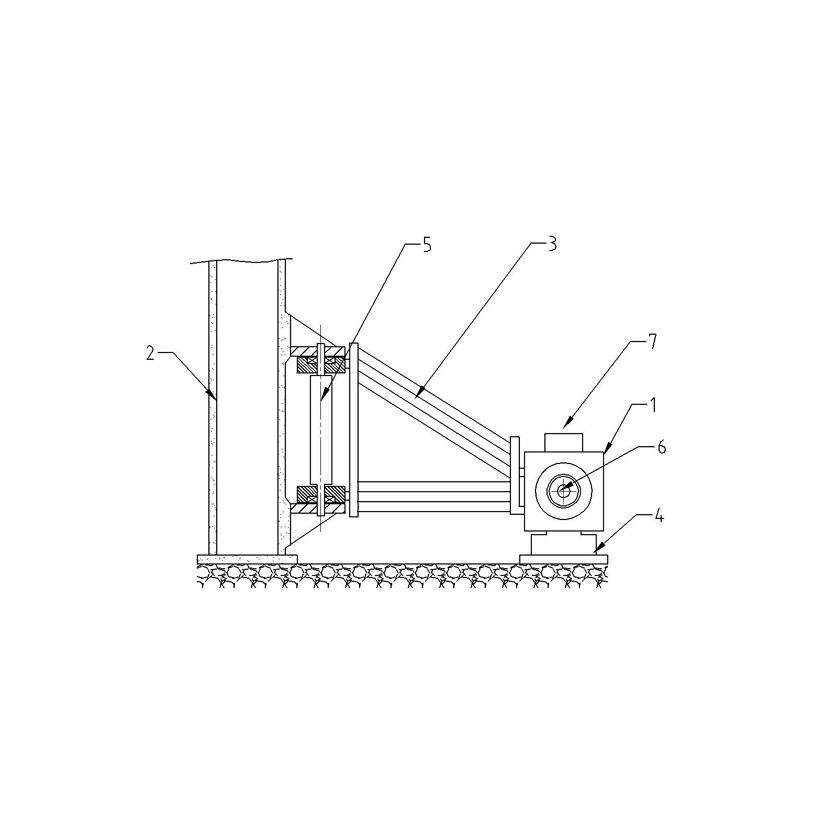

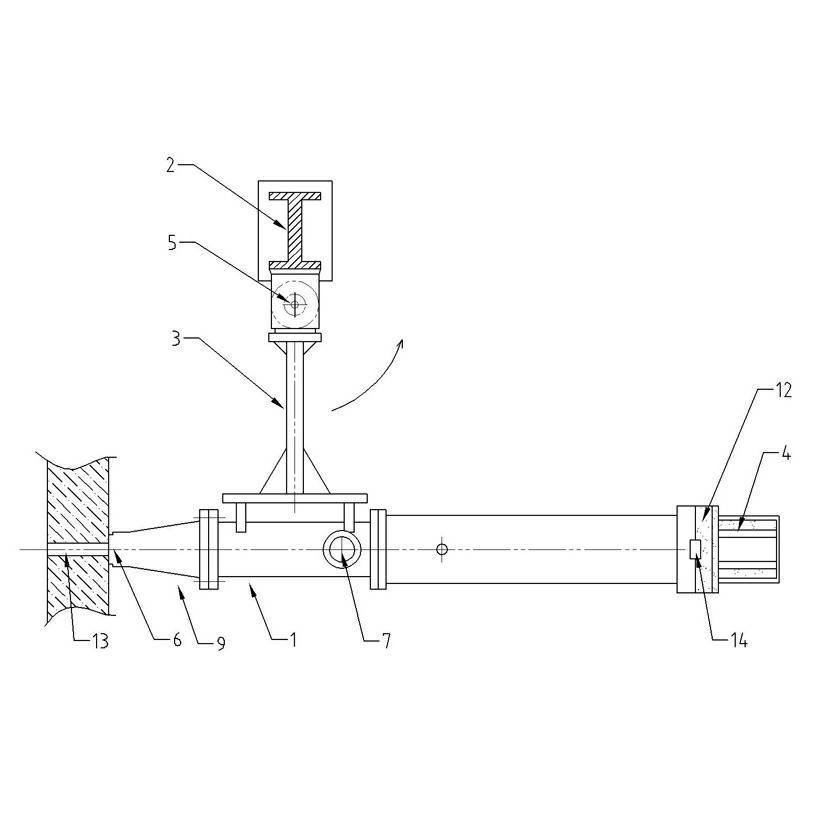

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0015] refer to Figure 1-4 , a mud cannon plugging machine for an oxygen-enriched smelting pool, consisting of a mud cannon tube 1, a column 2, a cantilever 3 and a thrust corbel 4; one end of the cantilever 3 is fixed to the side of the middle part of the mud cannon tube, and the other end passes The rotating shaft 5 is hinged with the column 2; the mud blocking gun tube 1 has a mud outlet nozzle 6 at the front end, a mud loading port 7 at the upper middle part, and the mud loading port 7 is connected to the internal mud pushing cylinder 8, and the rear end has a guide half groove. Tailstock; the front end of the mud pushing cylinder 8 is connected to the mud nozzle 6 through the nozzle cone 9; there is a mud pushing plate 10 in the mud pushing cylinder 8, and the rear end of the mud pushing plate 10 is connected to the mud gun barrel thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com