Embedded high manganese steel frog structure

A high-manganese steel, embedded technology, applied in the direction of switches, roads, tracks, etc., can solve the problems of unfavorable casting, machining and assembly, complex frog structure, low production efficiency, etc., to achieve machining and assembly. Good, enhance the overall stability, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

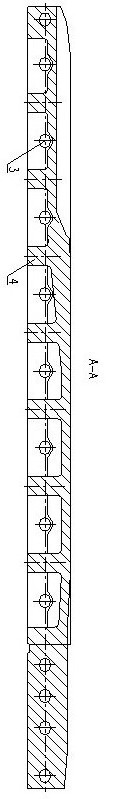

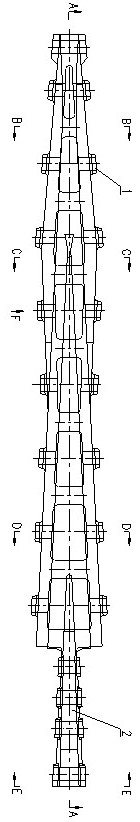

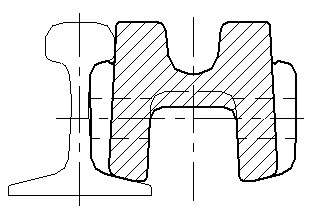

[0019] Embodiment 1: with reference to attached Figure 1-6 . An embedded high-manganese steel frog structure, which includes a high-manganese steel frog, and the high-manganese steel frog spacer plate 1 is an outwardly convex structure, and is intermittently distributed in frog bolt holes 3; the high-manganese steel frog The spacer iron 2 at the heel end of the fork is a solid structure; the outer walls 5 on both sides of the frog made of high manganese steel have uniform wall thickness, and form a box-shaped structure with the transverse reinforcement 4 . The high manganese steel frog transverse reinforcement 4 is 60-100mm wide, the upper side is connected to the rail top, and the lower side ensures the space for setting the riser. Its manufacturing process belongs to the prior art and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com