Wall patch

A technology for repairing walls and metal plates, applied in the field of wall repairing panels, can solve the problems of thickness, heavy weight, and easy water seepage of the repairing wall panels, and achieve the effect of reducing the overall thickness, lightening the whole, and increasing resistance to external forces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

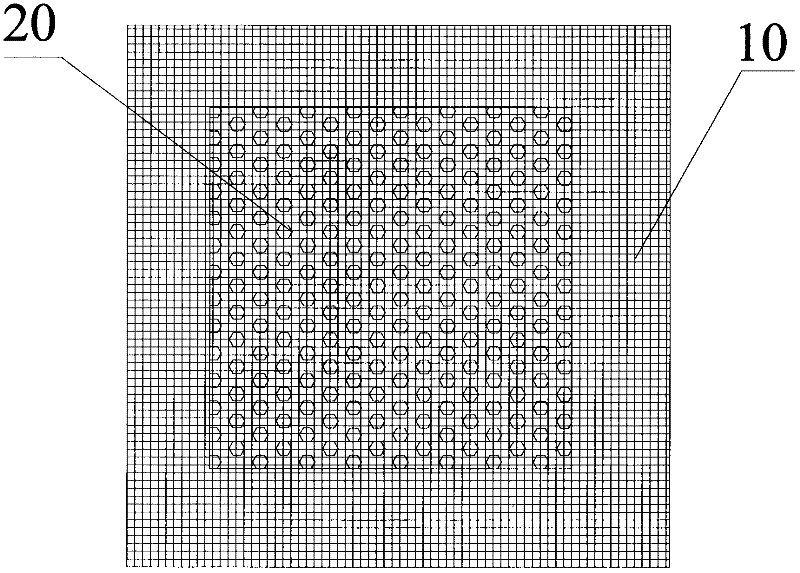

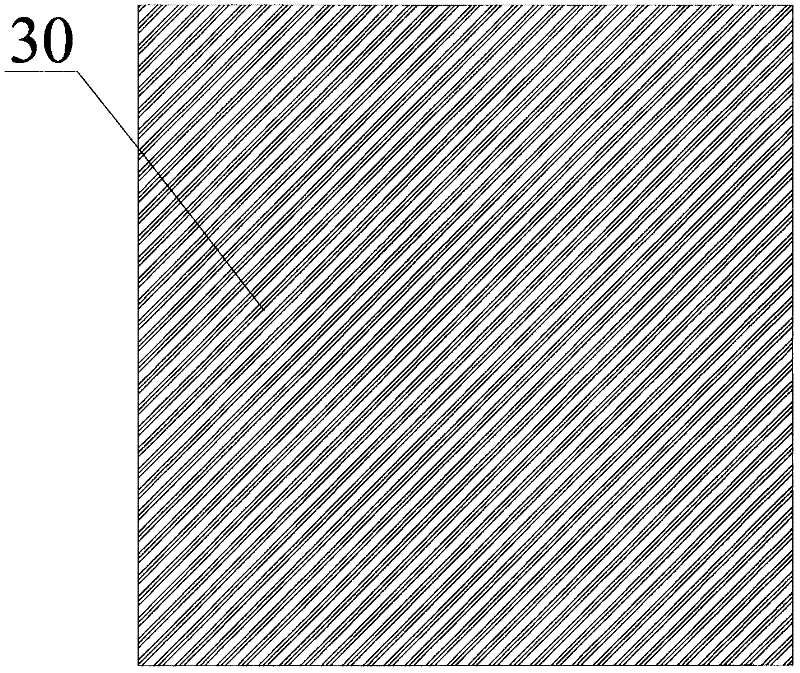

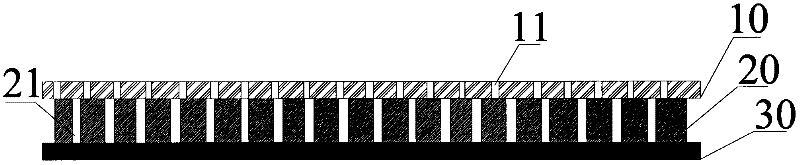

[0017] see Figure 1-3 , the glass fiber mesh 10 is bonded to the front of the aluminum alloy plate 20 with several holes through self-adhesive, and the back of the aluminum alloy plate 20 is bonded to the release paper 30, wherein the thickness of the aluminum alloy plate 20 is 100 μm, and the aluminum alloy plate The diameter of the holes 21 on the 20 is 1 mm, and there are 200 holes 11 on the glass fiber mesh 10 per square inch unit area.

[0018] First remove the oxide film on the surface of the aluminum alloy plate 20, and then open some holes 21 on the aluminum alloy plate 20, so that the putty can penetrate into it during construction; Stick to the back side of the aluminum plate, make the two tightly combined, paste one deck ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com