Slipping luffing mechanism for crossbeam of horizontal directional drilling machine

A technology of horizontal directional drilling rig and luffing mechanism, which is applied in the direction of drilling equipment, earthwork drilling and production, supporting devices, etc. It can solve problems such as unstable operation, left and right shaking, and beam distortion, and achieve stable and reliable operation and increase climbing Angle, overcoming unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

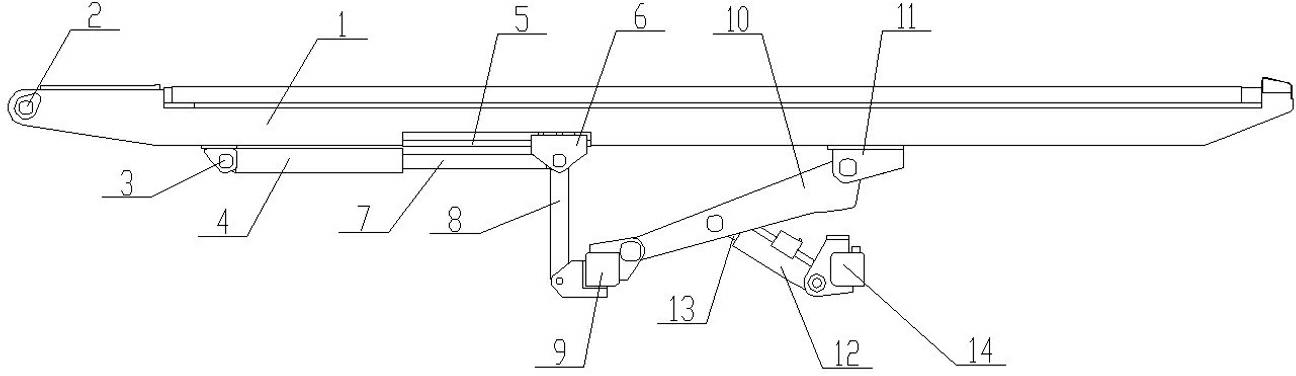

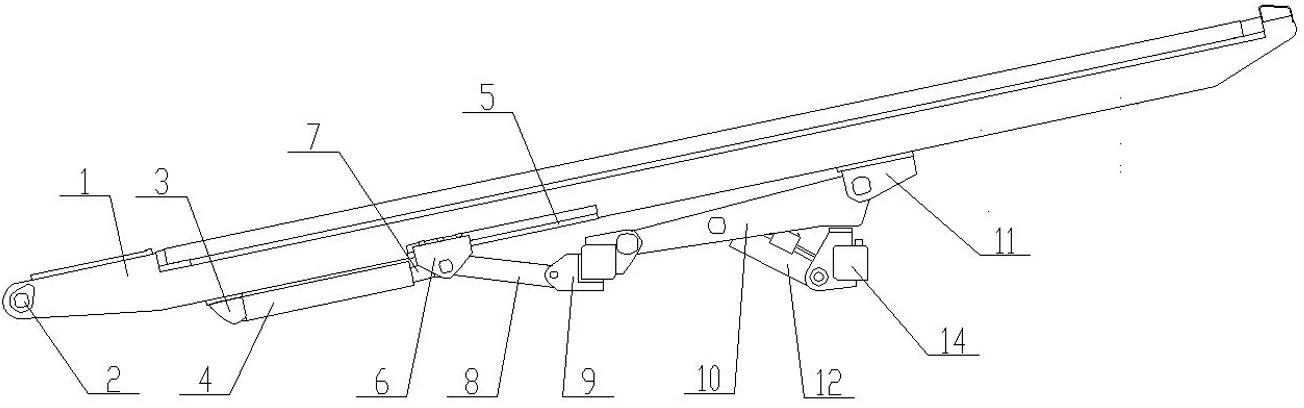

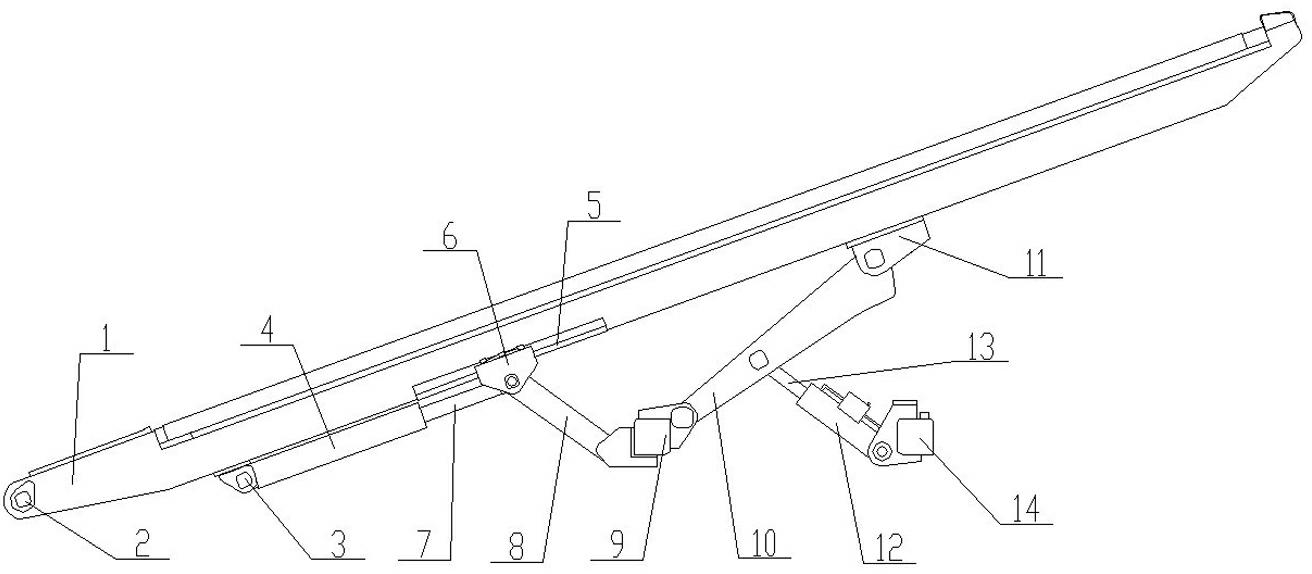

[0012] Such as figure 1 , figure 2 , image 3 As shown, the girder sliding luffing mechanism of the horizontal directional drilling rig includes: the girder 1, one end of the girder 1 is arranged on the chassis of the horizontal directional drilling rig through the fixing hole 2 and the bolt, and the lifting cylinder 4 is connected to the girder 1 through the hinge 3, A guide rail 5 is provided on the girder 1, and a sliding winch 6 is slidably arranged on the guide rail 5. The sliding winch 6 is respectively connected with the piston rod 7 of the lifting cylinder 4 and one end of the lifting connecting rod 8, and the lifting connecting rod 8 The other end of the connecting rod hinge seat 9 is connected with one end of the connecting rod hinge seat 9, and the other end of the connecting rod hinge seat 9 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com