Micro acceleration transducer-based cooking state control method for electromagnetic oven boiler

A technology of micro-acceleration and state control, which is applied to home appliances, household stoves/stoves, electric heating fuel, etc., can solve the problems of time lag and poor accuracy, and achieve the effect of improving accuracy and eliminating time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

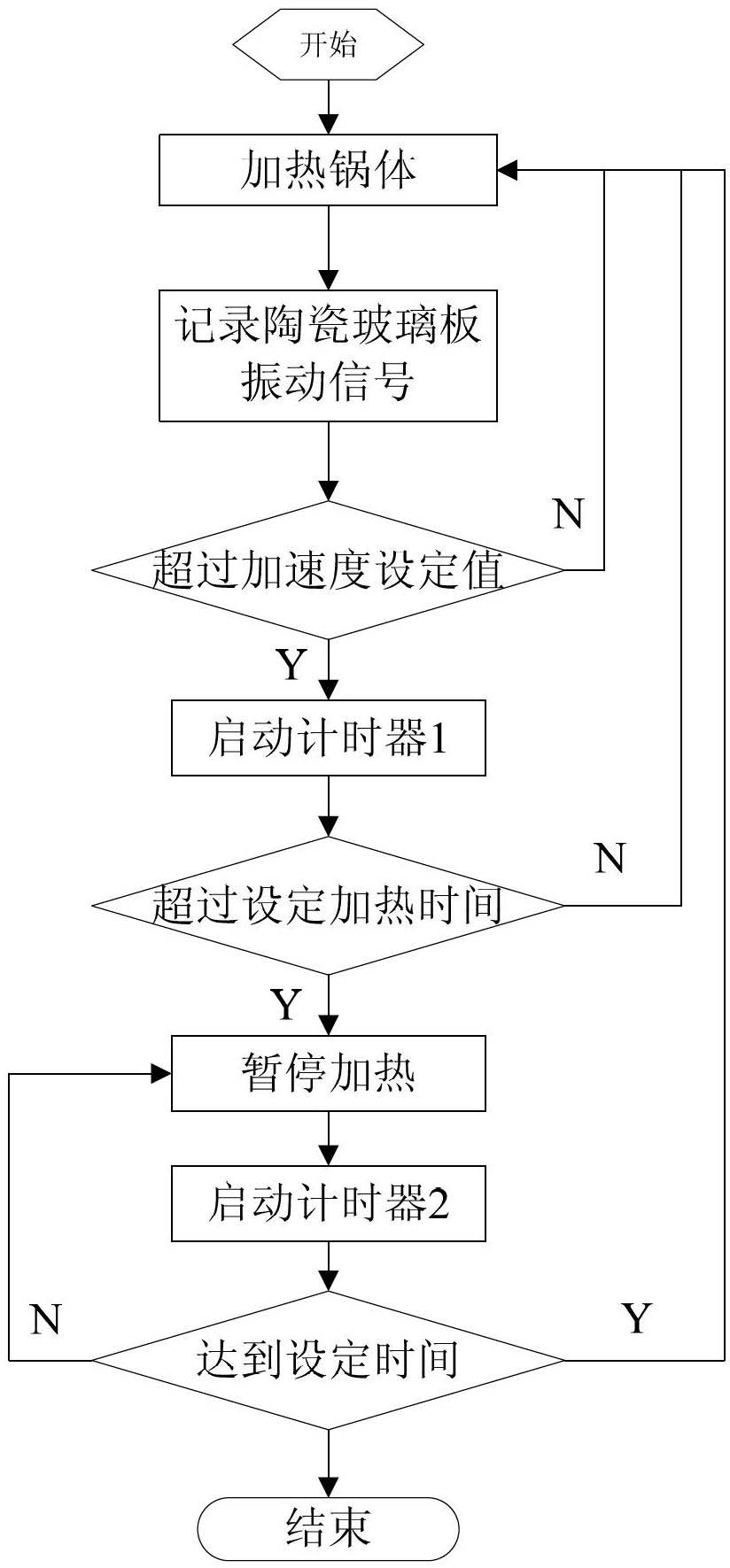

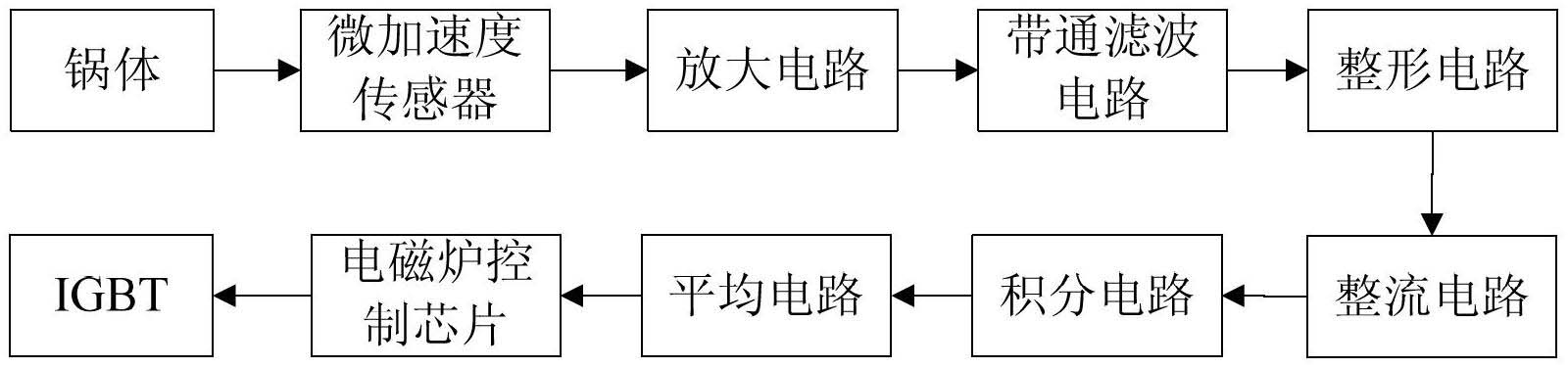

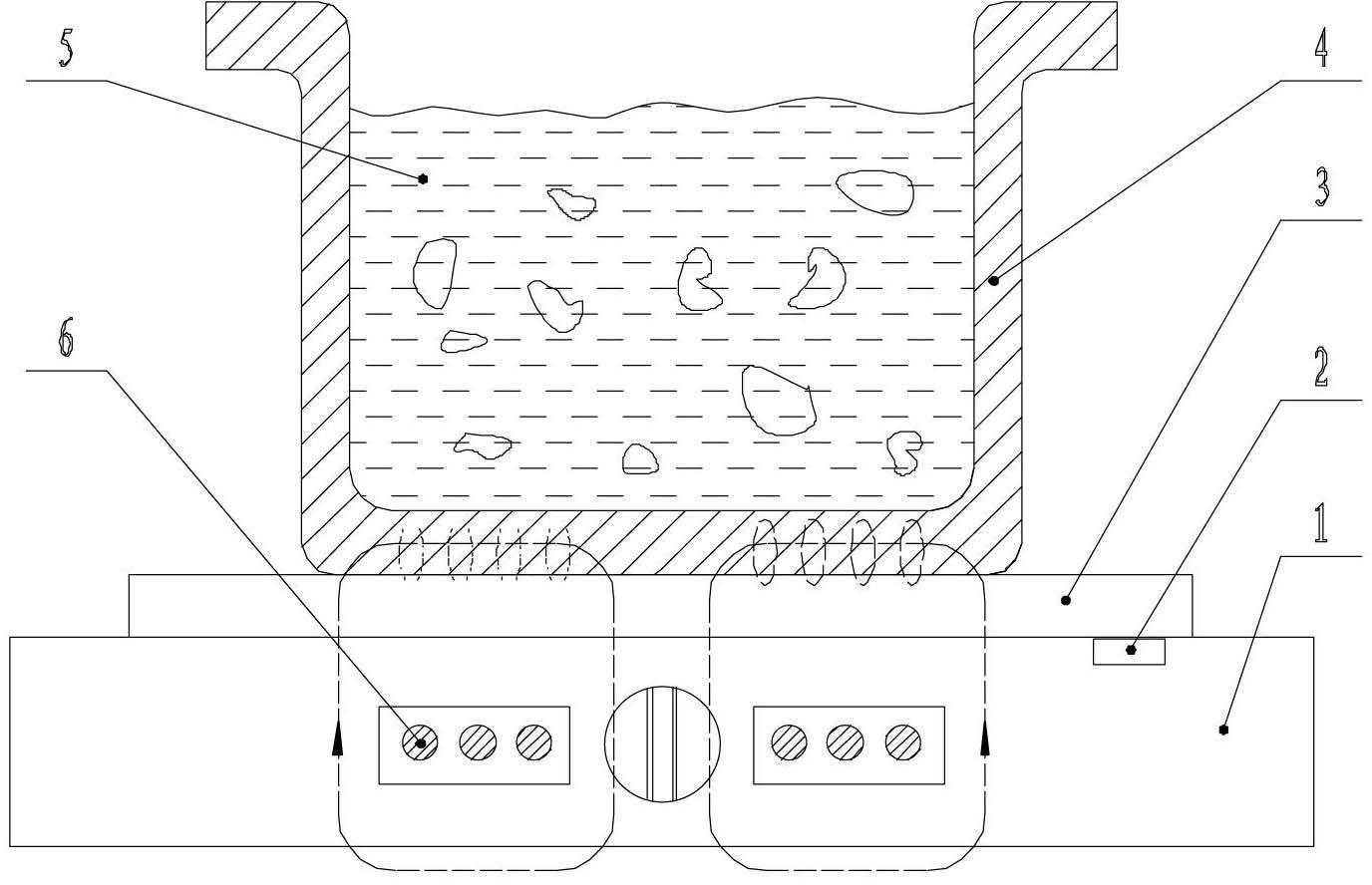

[0017] refer to Figure 1 to Figure 4 , a method for controlling the cooking state of an electromagnetic cooker based on a micro-acceleration sensor. In the electromagnetic cooker body 1, below the contact position of the pot body 4 and the ceramic glass plate 3, the ceramic glass plate is close to the side of the furnace body, and one or equally divided along the circumference Several micro-acceleration sensor chips 2 are positioned to detect the vibration signal transmitted from the pot body 4 to the ceramic glass plate 3 . When using the induction cooker, the pot body filled with food and water is placed on the ceramic glass panel, the power is turned on, and the pot body 4 is heated by the induction coil 6 . During the heating process, the vibration of the ceramic glass plate 3 is monitored in real time through the micro-acceleration sensor chip. The tested vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com