Device for automatically detecting spool displacement of electromagnetic valve with high precision and method thereof

A technology of automatic detection and spool displacement, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficulty in meeting the needs of large-scale production, increasing the workload of operators, and low efficiency, so as to save manpower and material resources, realize automatic operation, increase safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

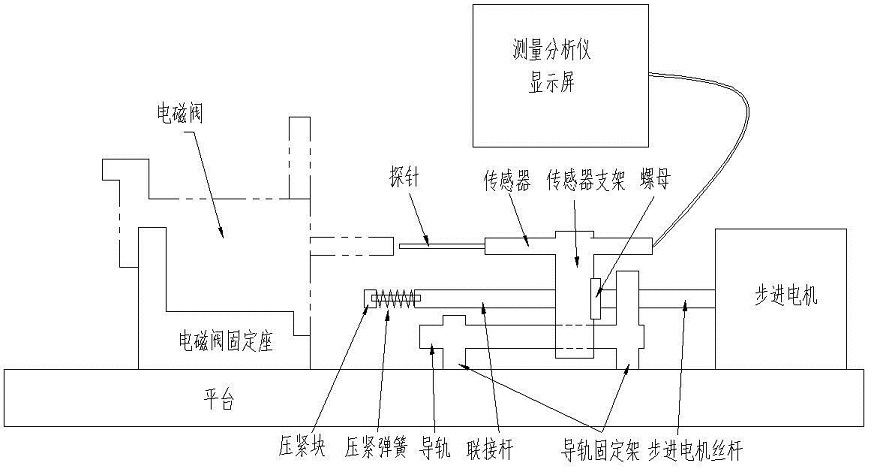

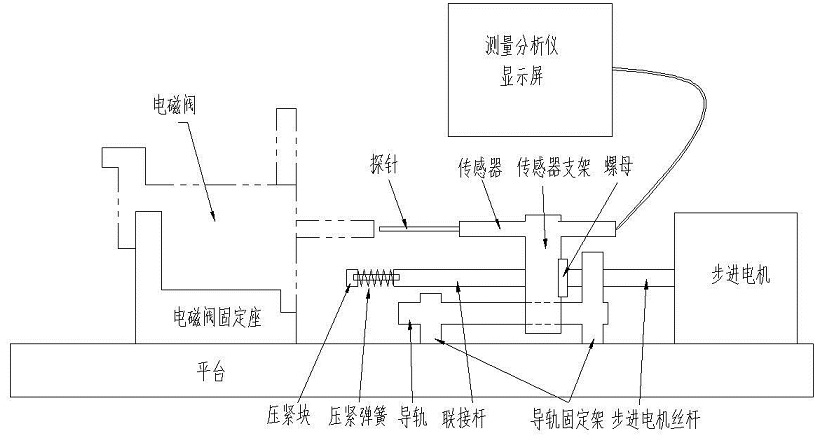

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The device of this embodiment can automatically clamp the solenoid valve to be tested, automatically send the detection sensor probe, automatically connect the power supply of the solenoid valve, automatically record the displacement of the solenoid valve core, judge whether it is qualified and perform corresponding display and reminder. The installation steps are:

[0020] 1) On the rectangular cast iron platform, install the solenoid valve fixing seat;

[0021] 2) On the rectangular cast iron platform, install the sensor bracket guide rail;

[0022] 3) On the rectangular cast iron platform, install the stepper motor;

[0023] 4) Install the sensor bracket on the sensor rail;

[0024] 5) A nut is installed on the stepper motor rotating screw;

[0025] 6) Connect the nut and the sensor bracket fixedly;

[0026] 7) The nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com