Multi-rotary absolute value rotary encoder

An absolute value, coding technology, applied in the field of sensors (encoders), can solve problems such as inability to meet needs, incomplete functions or performance, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

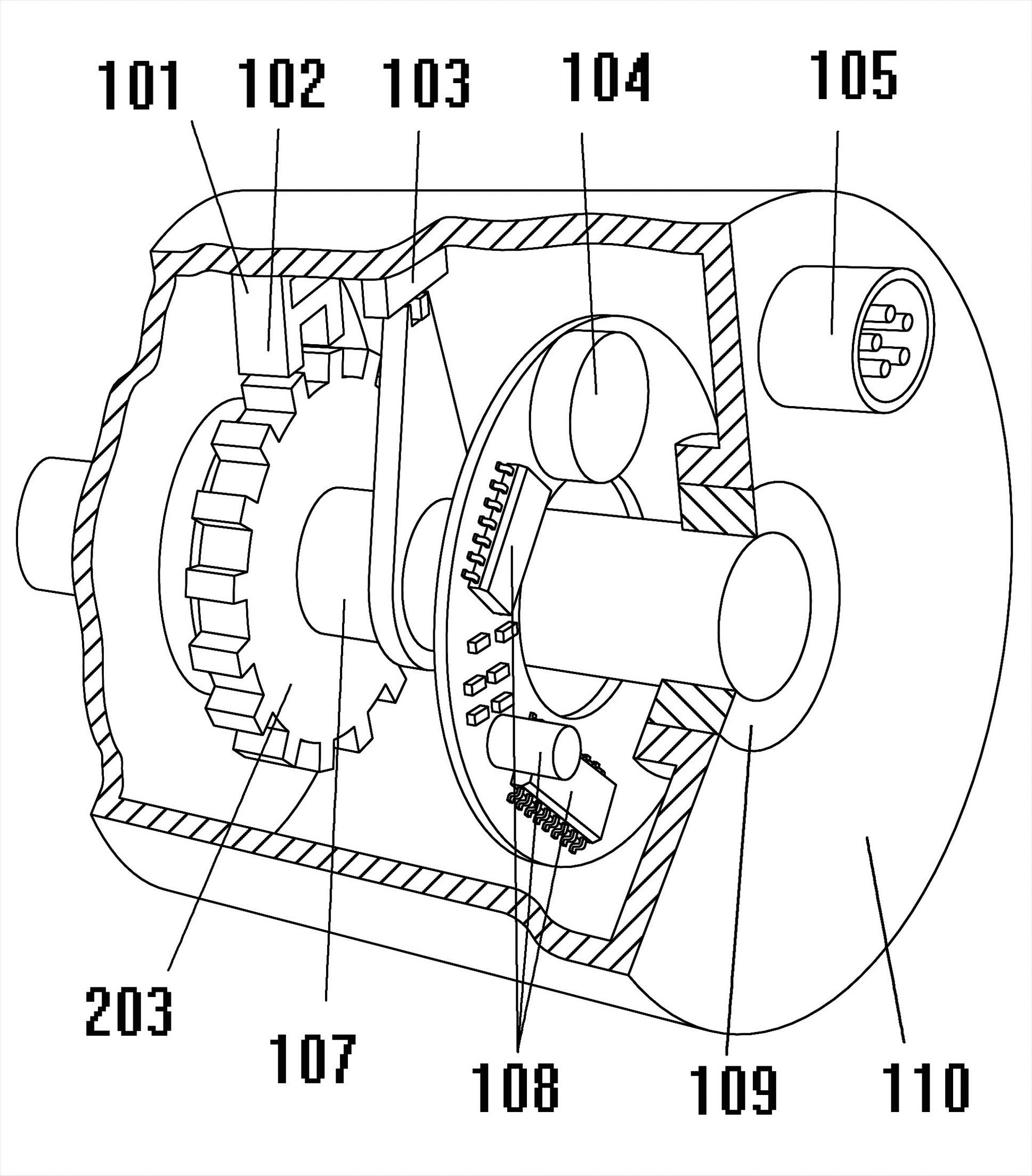

[0063] refer to figure 1 In addition to the necessary conventional structures such as the backup power supply 104, the data interface 105, the input shaft 107, the processing circuit 108, the bearing 109, and the housing 110, an active ferromagnetic component 203 with a raised structure is specially designed to fix the On the input shaft 107, rotating together with it, the ferromagnetic ratchet 203 drives a passive ferromagnetic sensor assembly 102, and among these two ferromagnetic assemblies, choose one (this illustration is in the ferromagnetic sensor assembly 102) Install the elastic damping energy storage structure 101.

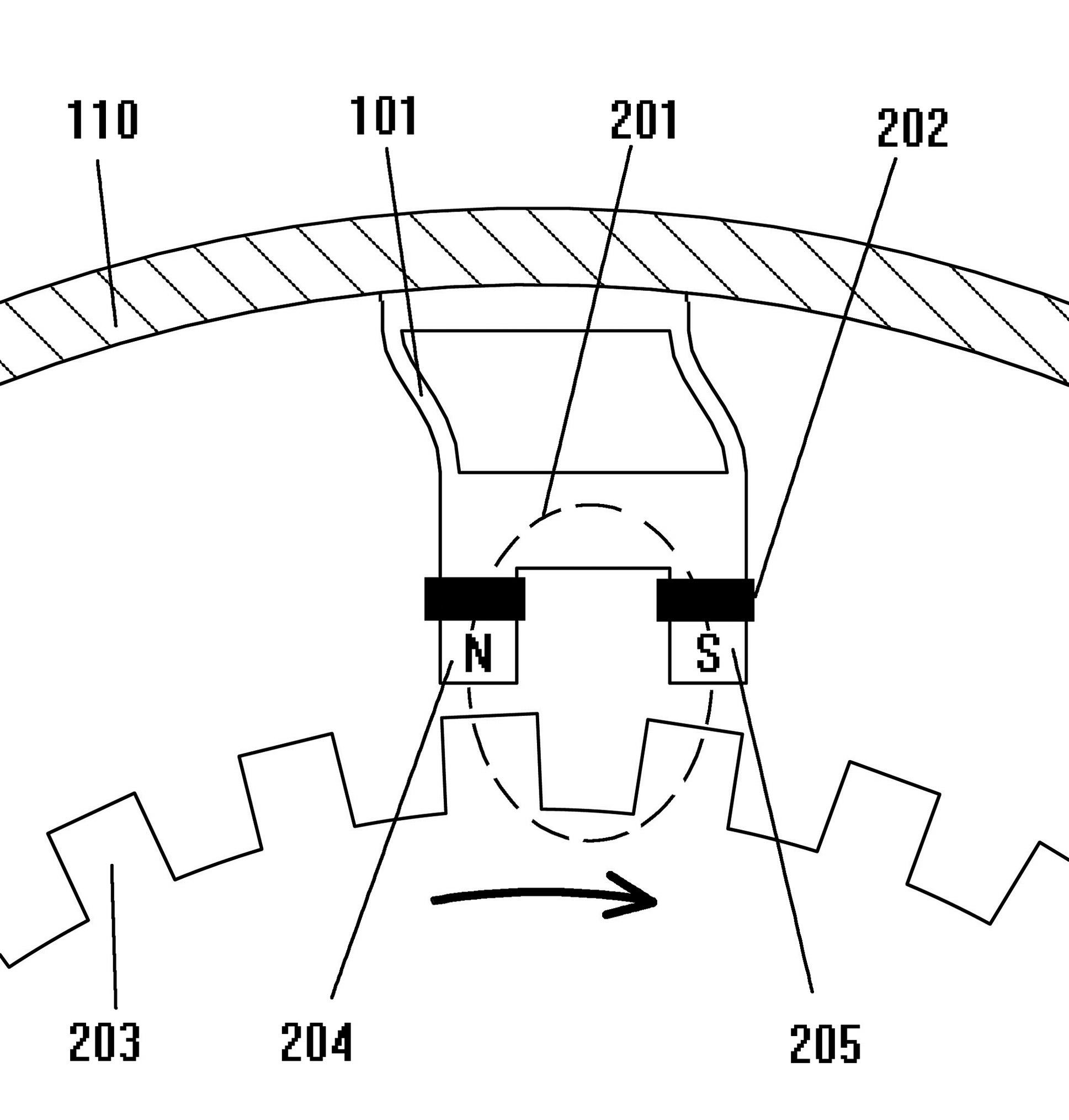

[0064] figure 1 For details near the ferromagnetic sensing assembly 102, see figure 2 , the ferromagnetic sensing component 102 is mainly composed of figure 2 Middle sensor coil 202, sensor N pole 204, sensor S pole 205

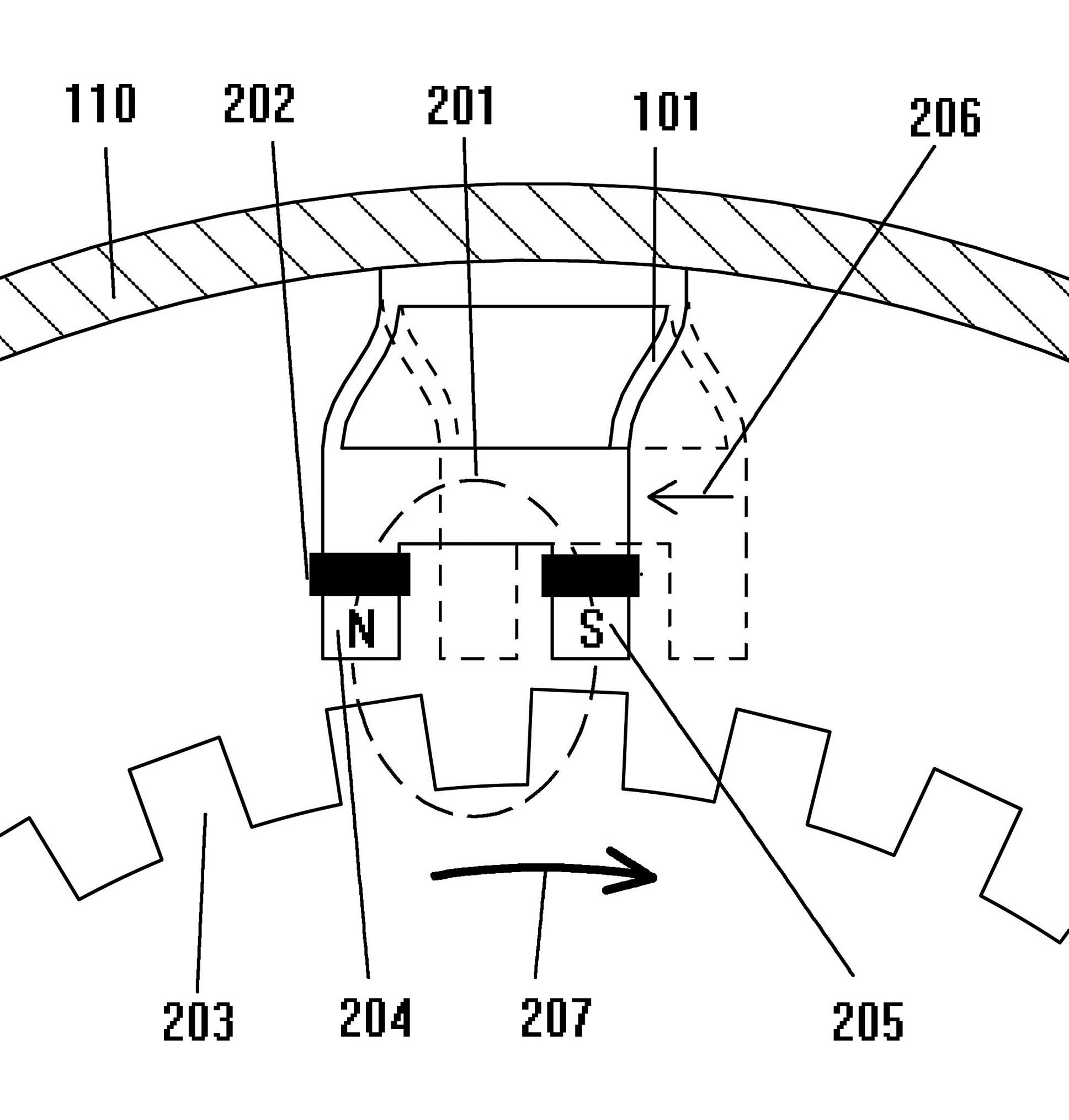

[0065] refer to image 3 , when the two ferromagnetic components 203 and 102 generate a relative motion trend, under the joint ...

Embodiment 2

[0067] Exemplary overall embodiment two (see Figure 4 ):

[0068] Most of them are consistent with Embodiment 1, only the sensing components are divided into two sets, which are respectively driven by two reversely installed one-way bearings 301, that is, one of the two ferromagnetic ratchets will only rotate clockwise with the input shaft, and the other It will only turn counterclockwise with the input shaft.

Embodiment 3

[0069] Exemplary overall embodiment three (see Figure 5 ):

[0070] Most of the structures are the same as the first embodiment, except that the type of the sensor has been changed. Here, the power generation capability of the piezoelectric ceramic 401 is used to realize the conversion of the displacement and the electric signal. When the cam 402 rotates one tooth, the piezoelectric sensing head will swing and knock once to output an electric pulse signal. In the actual implementation, because of the characteristic of vibration, the piezoelectric ceramic sensor can be installed in any sensitive part. The action diagram of this embodiment can be found in Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com