Method for automatic identification and detection of defect in composite material

A technology for composite materials and internal defects, applied in the field of automatic identification and detection of internal defect types in composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

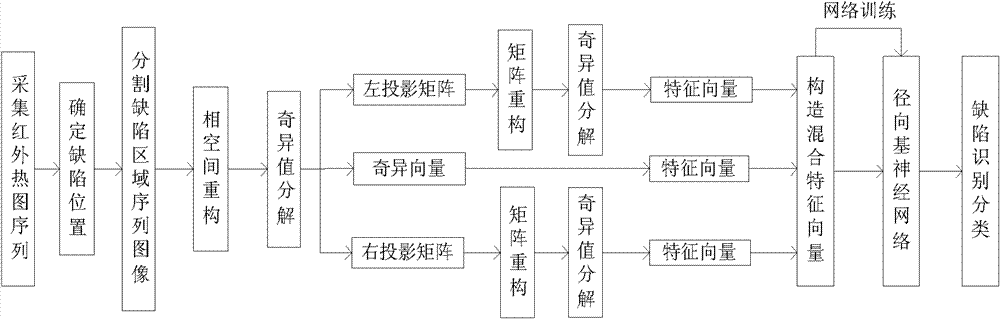

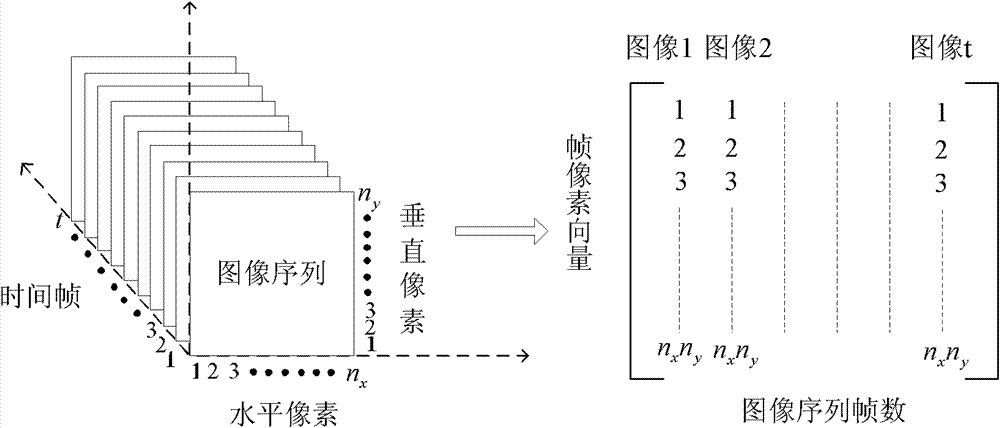

[0040] The method for automatic identification and detection of internal defects in composite materials proposed by the present invention is based on infrared non-destructive testing technology. structure, determine the position of the defect in the composite material and segment the defect area of the image; reconstruct the phase space of the infrared sequence image with the defect area, perform singular value decomposition to obtain a singular matrix and two projection matrices, and reconstruct the above two projection matrices Reconstruction, extract the algebraic features of defect time information and spatial information through singular value decomposition again, and construct a mixed feature vector as the feature representation of defects; use the RBF neural network classifier to generate known defect samples by extracting defect feature representations The training set is used as the input of the neural network to complete the network training of defect classification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com