Three-core optical fiber composite submarine cable

A technology of submarine cable and three-core optical fiber, applied in the direction of submarine cable, power cable, cable, etc., can solve the problems of energy loss, mechanical damage of submarine cable, occupation of route width, etc., and reduce the probability of mechanical damage and mechanical loss. , the effect of reducing the occupied routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

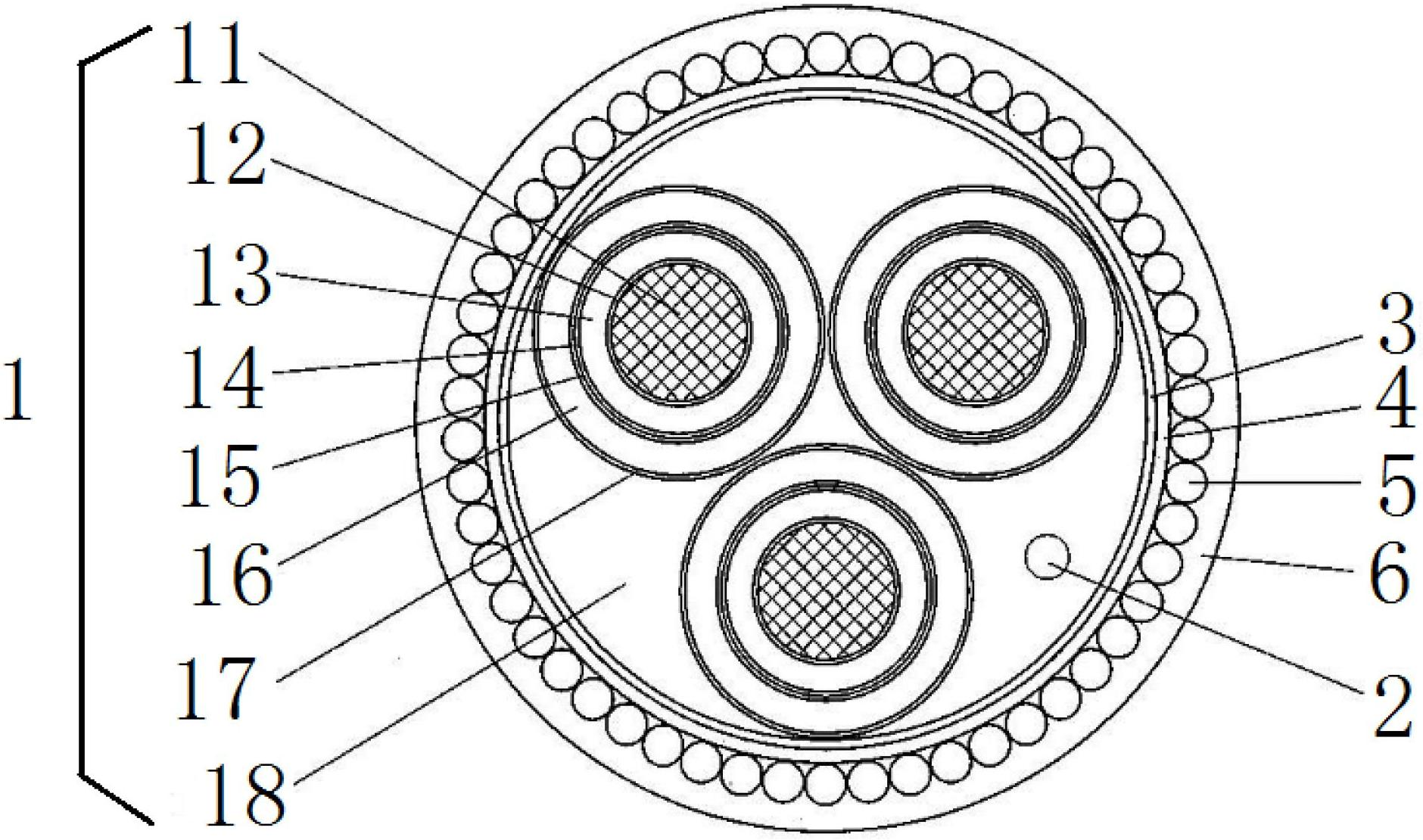

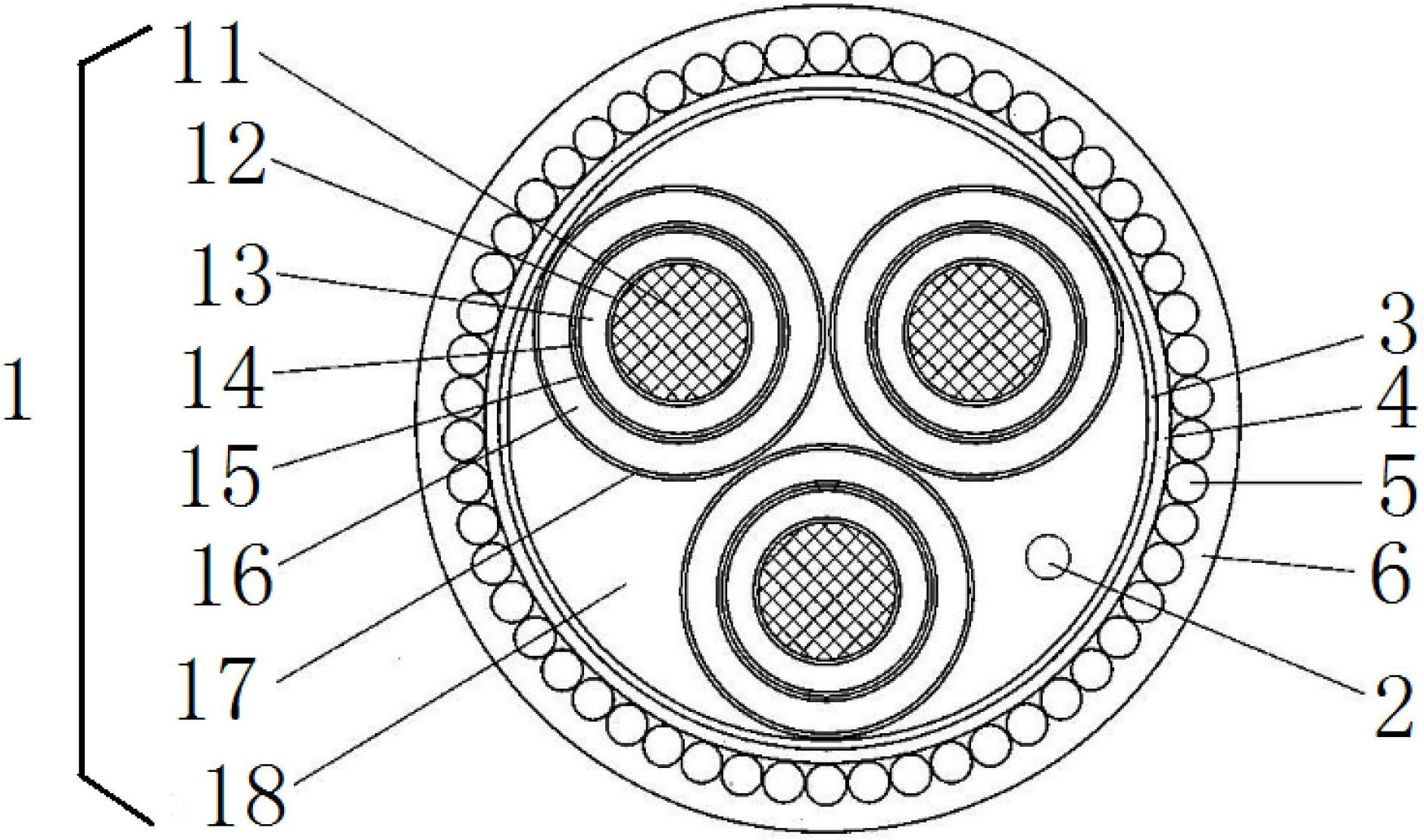

[0026] As shown in the accompanying drawings, it provides three cable cores 1 and one optical cable unit 2 for forming a power transmission circuit. Each cable core 1 includes a water-blocking conductor 11 and an insulating layer positioned outside the water-blocking conductor 11 in turn. 13. Shielding layer 14, water blocking layer 15, lead layer 16 and sheath layer 17.

[0027] The water-blocking conductor 11 is a conductor in which gaps between wires constituting the water-blocking conductor 1 are filled with water-blocking materials. Because the water-blocking conductor 11 is also called a cable core conductor, and the cable core conductor is composed of a plurality of wires arranged in a cylindrical shape, the gaps between the wires are filled with a filler preferably water-blocking powder.

[0028] A semi-conductive layer 12 is arranged between the water-blocking conductor 11 and the insulating layer 13. The semi-conductive layer 12 is also called a semi-conductive resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com