Perpendicular orthogonal interconnection system and communication device

A technology for interconnecting systems and communication equipment, applied in the field of communication, can solve problems such as difficult orthogonal architecture upgrades, and achieve the effects of saving material costs, shortening signal links, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

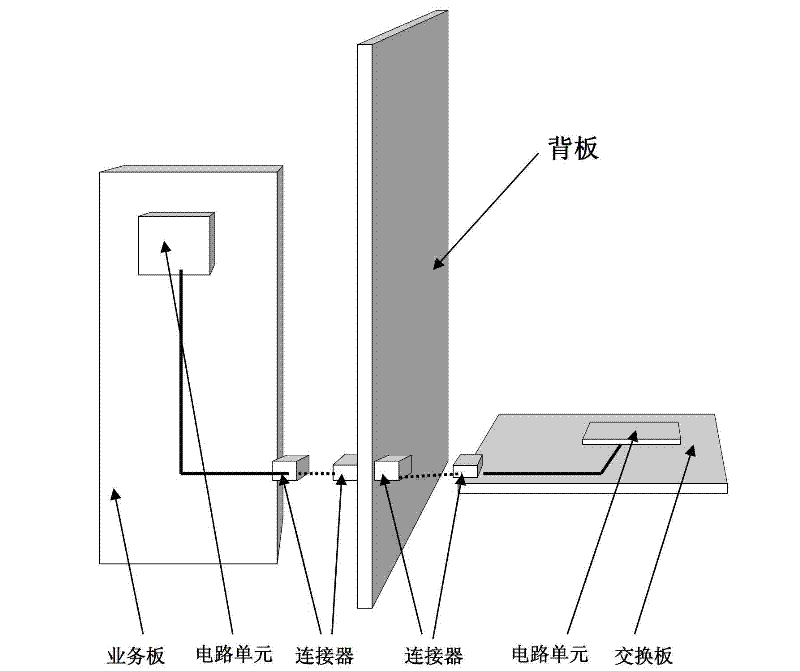

Problems solved by technology

Method used

Image

Examples

Embodiment 1

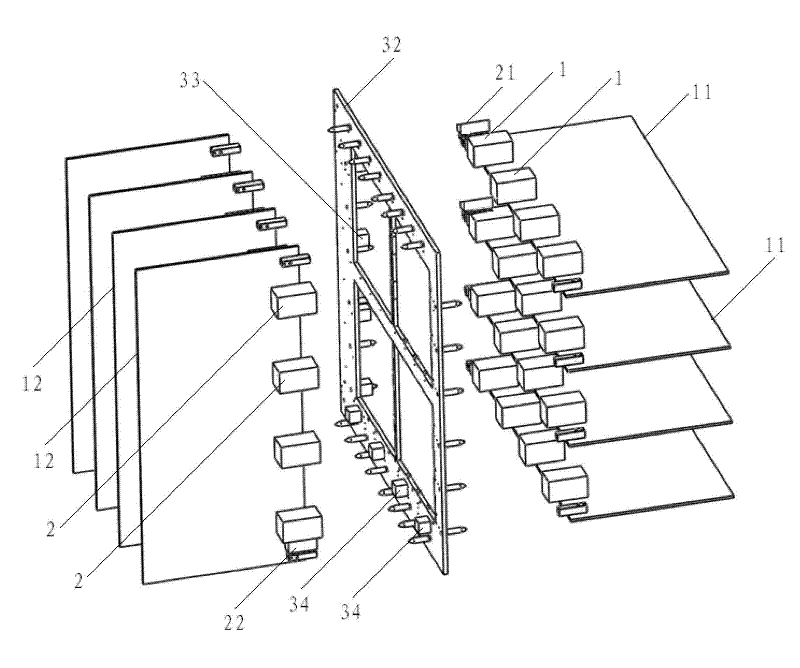

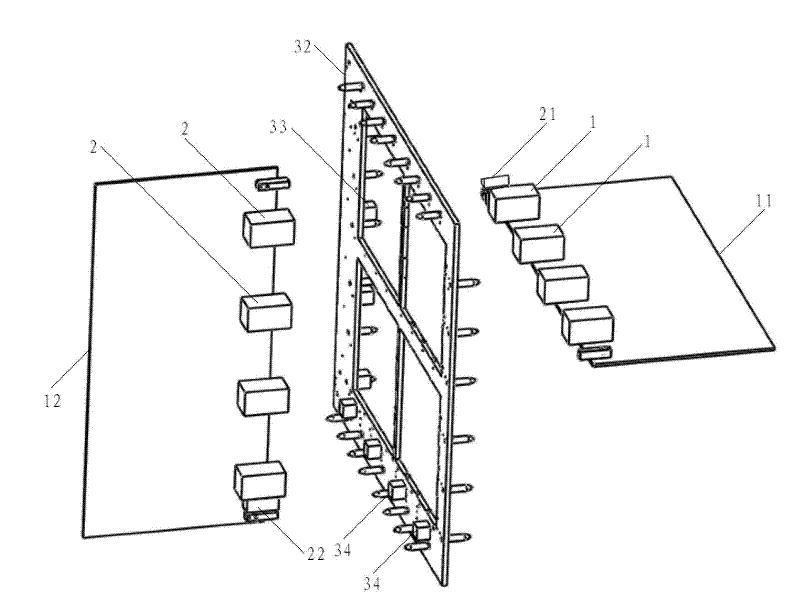

[0019] Such as figure 2 , 3 As shown, the vertical orthogonal interconnection system provided by the embodiment of the present invention includes a first veneer group, a second veneer group orthogonal to the first veneer group, and a The middle backplane 32 between the two veneer groups; the first veneer group includes a plurality of first veneers 11 parallel to each other, and the second veneer group includes a plurality of second veneers 12 parallel to each other A plurality of curved male connectors 1 are arranged on the first veneer 11, a plurality of curved female connectors 2 are arranged on the second veneer 12, and the curved male connector 1 and the curved female connector 2 are one by one Corresponding to the direct mating connection, here the one-to-one correspondence between the male connector 1 and the female connector 2 constitutes an orthogonal connector. When upgrading the vertical orthogonal interconnection system, it is only necessary to replace the first ...

Embodiment 2

[0023] Such as Figure 4 As shown, the vertical orthogonal interconnection system provided by the embodiment of the present invention includes a first veneer group, a second veneer group orthogonal to the first veneer group, and a The middle backplane 37 between the two veneer groups; the first veneer group includes a plurality of first veneers 11 parallel to each other, and the second veneer group includes a plurality of second veneers 12 parallel to each other A plurality of curved male connectors 1 are arranged on the first veneer 11, a plurality of curved female connectors 2 are arranged on the second veneer 12, and the curved male connector 1 and the curved female connector 2 are one by one Corresponding to the direct mating connection, here the one-to-one correspondence between the male connector 1 and the female connector 2 constitutes an orthogonal connector. When upgrading the vertical orthogonal interconnection system, the first board group and the second board grou...

Embodiment 3

[0027] Such as Figure 5 As shown, the vertical orthogonal interconnection system provided by the embodiment of the present invention includes a first veneer group, a second veneer group orthogonal to the first veneer group, and a The middle backplane 38 between the two veneer groups; the first veneer group includes a plurality of first veneers 11 parallel to each other, and the second veneer group includes a plurality of second veneers 12 parallel to each other A plurality of curved male connectors 1 are arranged on the first veneer 11, a plurality of curved female connectors 2 are arranged on the second veneer 12, and the curved male connector 1 and the curved female connector 2 are one by one Corresponding to the direct mating connection, here the one-to-one correspondence between the male connector 1 and the female connector 2 constitutes an orthogonal connector. When upgrading the vertical orthogonal interconnection system, it is only necessary to replace the first venee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com