Medlar harvesting machine

A harvester and goji berry technology, which is applied to harvesters, pickers, agricultural machinery and implements, etc., can solve problems such as low work efficiency and poor working environment for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

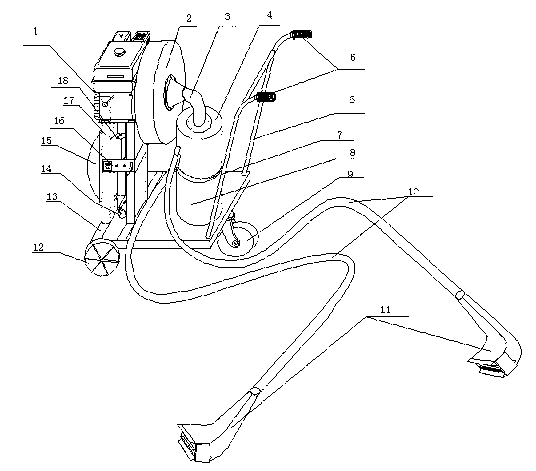

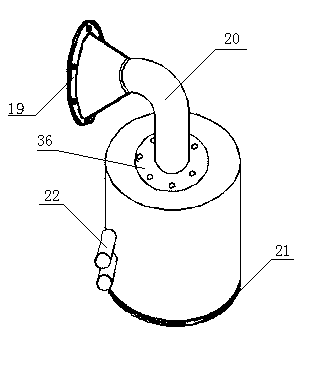

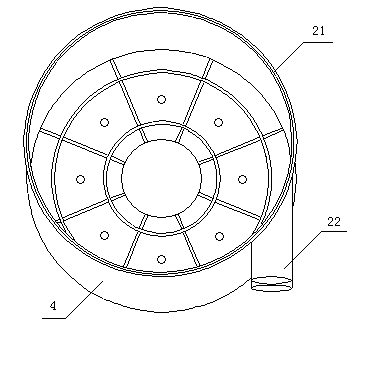

[0031] Such as figure 1 - Figure 10 As shown, a wolfberry harvester of the present invention includes an engine assembly 1, a centrifugal fan 2, a connector 3, a hand handle 5, a hand frame 6, a collection box 8, a steering wheel 9, a support wheel 12, and a harvester base 13 , engine support frame 17, described wolfberry harvester is provided with the special centrifugal fan 2, collector 11 and fruit separator 4 of wolfberry collection; Described centrifugal fan 2 is connected with exhaust pipe 20 upper end by connector 3, exhaust The lower end of the pipe 20 is connected to the upper end of the fruit separator 4, and the lower end of the fruit separator 4 is connected to the collection box 8 through a threaded interface 21; the feed port 22 on the side of the fruit separator 4 is connected to the collector 11 through the delivery pipe 10; Water tank 15 is set on the engine supporting frame 17 described above, and high-pressure water pump 14 is installed on harvester base 1...

Embodiment 2

[0052] This embodiment adopts as Figure 6 Shown large-angle collector 35 collects Lycium barbarum fruit, and large-angle collector 35 can collect the fruit of Lycium barbarum that knots higher in branches. All the other installations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com