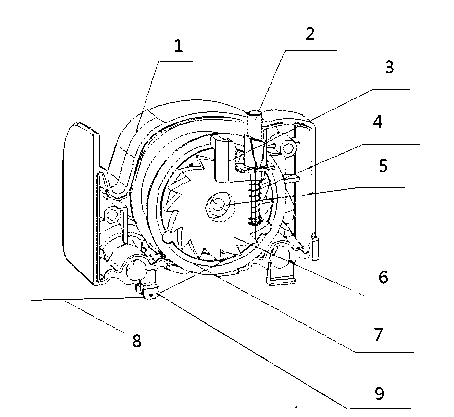

Volute energy storage pushing trolley with braking device

A technology with brakes and energy storage, which is applied in storage devices, transportation and packaging, etc., can solve the problems that the pushing trolley does not have a braking function, and the pushed items cannot be stopped at any time, and achieves simple structure, low failure rate, and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

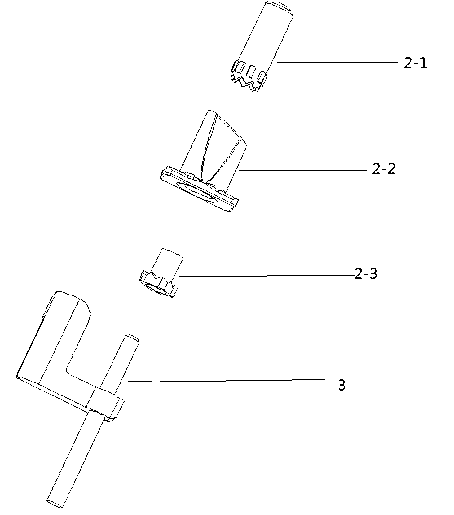

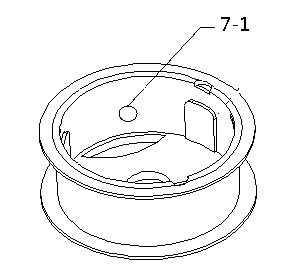

Method used

Image

Examples

Embodiment 1

[0029] When pushing the boxed items, first fix the front end of the traction line on a fixed object, and pull the trolley backwards by hand. At this time, the worm coil disk rotates, the worm coil spring stores energy, and the boxed items are arranged neatly and placed on the bottom plate , then loosen the hand to release the trolley, the worm coil spring releases energy, the worm coil disk rotates in another direction and pulls the traction wire, the trolley will move forward and push the boxed items in front of it to move, and finally the boxed items will be out of the warehouse .

[0030] When you need to stop the trolley in an unexpected situation, you can press the brake button device at any time. At this time, the trolley is locked and cannot move; when the accident is eliminated, you can press the brake button device again, the trolley lock is released, the car continues to move.

[0031] The pushing device of the present invention can stop pushing at any time, and can...

Embodiment 2

[0033] When pushing bottled items, first fix the front end of the traction line on a fixed object, and pull the trolley backward by hand. At this time, the worm coil disk rotates, and the worm coil spring stores energy. The bottled items are arranged neatly and placed on the bottom plate, and then Release the hand to release the trolley, the worm coil spring releases energy, the worm coil disk rotates in another direction and pulls the traction wire, the trolley will move forward and push the bottled items in front of it to move, and finally the bottled items will be out of the warehouse.

[0034] When you need to stop the trolley in an unexpected situation, you can press the brake button device at any time. At this time, the trolley will be locked and the trolley cannot move; Release, the car continues to move.

[0035] The pushing device of the present invention can stop pushing at any time, can determine the parking position in batches according to the size of the items, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com