Method for continuously producing lactate by utilizing heavy phase lactic acid

A technology of heavy-phase lactic acid and lactate, applied in the preparation of carboxylate, organic chemistry, etc., can solve the problems of small dosage, difficult to sell, narrow use of heavy-phase lactic acid, etc., and achieves the effect of solving constraints and rational utilization of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the method for continuously producing lactate using heavy-phase lactic acid comprises the following steps:

[0030] (a) Dilution: Dilute the heavy phase lactic acid to a mass fraction of lactic acid of 20%;

[0031] (b) Carbon column decolorization: the carbon column is filled with granular carbon, and the heavy phase lactic acid to be extracted is obtained after decolorization of the carbon column;

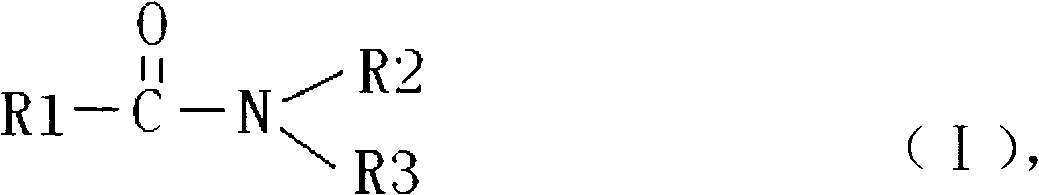

[0032] (c) Extraction: The organic extraction phase is composed of an extractant, a solvent and a phase regulator. The extractant is an amide compound, the solvent is liquid paraffin, and the phase regulator is an alcohol compound. Amide compound has the structure shown in following formula (I):

[0033]

[0034] where R1 is CH 3 (CH 2 ) 3 -, R2 is hydrogen, R3 is CH 3 (CH 2 ) 3 -.

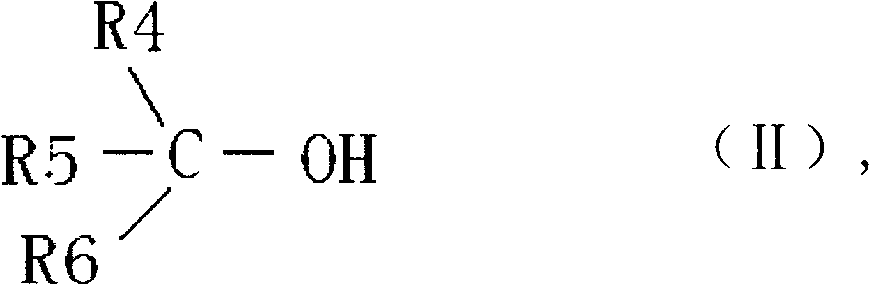

[0035] Alcohol compound has the structure shown in following formula (II):

[0036]

[0037] Wherein R4 is hydrogen, R5 is hydrogen, R6 is CH 3 CH 2 -.

...

Embodiment 2

[0046] The difference between this example and Example 1 is: in step (a), dilute the heavy phase lactic acid to a mass fraction of lactic acid of 30%; in step (c): the mass ratio of the extractant, solvent and phase regulator 6.5:3.5:1. The extraction agent is an amide compound, the solvent is liquid paraffin, and the phase regulator is an alcohol compound.

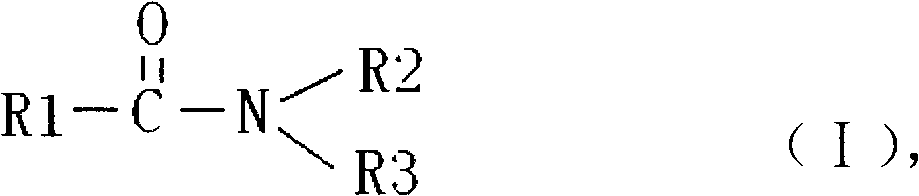

[0047] Amide compound has the structure shown in following formula (I):

[0048]

[0049] where R1 is (CH 2 ) 5 CH-, R2 is hydrogen, R3 is CH 3 (CH 2 ) 7 -.

[0050] Alcohol compound has the structure shown in following formula (II):

[0051]

[0052] Wherein R4 is hydrogen, R5 is hydrogen, R6 is CH 3 (CH 2 ) 5 -.

[0053] The organic extract phase and the heavy phase lactic acid to be extracted are fully mixed according to the mass ratio of 1.5:1, the extraction operating temperature is 33°C, the phases are separated and the phase equilibrium time is 36min; the mass fraction of lactic acid in the water pha...

Embodiment 3

[0057] The difference between this example and example 1 is: in step (a), dilute the heavy phase lactic acid to a mass fraction of lactic acid of 25%; in step (c): the mass ratio of the extractant, solvent and phase regulator 6:3:0.8. The extraction agent is an amide compound, the solvent is liquid paraffin, and the phase regulator is an alcohol compound.

[0058] Amide compound has the structure shown in following formula (I):

[0059]

[0060] where R1 is CH 3 (CH 2 ) 9 -, R2 is hydrogen, R3 is CH 3 (CH 2 ) 6 -.

[0061] Alcohol compound has the structure shown in following formula (II):

[0062]

[0063] Wherein R4 is hydrogen, R5 is hydrogen, R6 is CH 3 CH 2 -.

[0064] The organic extraction phase and the heavy phase lactic acid to be extracted are fully mixed according to the mass ratio of 1.3:1, the extraction operation temperature is 33°C, the phases are separated and the phase equilibrium time is 50min; the mass fraction of lactic acid in the aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com