A method for preparing 3-chloro-4-methylaniline

A technology of methylaniline and p-nitrotoluene, which is applied in the field of preparation of 3-chloro-4-methylaniline, can solve problems such as complex processes and increased energy consumption, and achieve the goal of saving raw materials and reducing energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

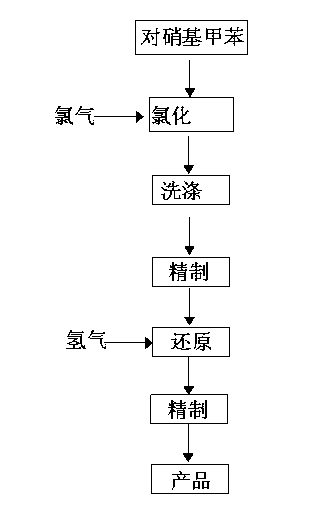

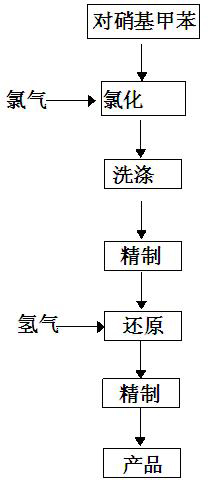

[0015] figure 1 A preparation method of 3-chloro-4-methylaniline is shown, the method comprises the following steps: passing 0.48-0.54 parts by weight of p-nitrotoluene under the condition of stirring process temperature (70°C-80°C) Chlorine is chlorinated in the chlorine tank, and after stirring for 10 minutes, put the material in the chlorine tank into the washing tank for washing; transfer the washed material to the rectification tank for refining, and then enter the reduction tank with a catalyst. A tower, introducing 0.038-0.044 parts by weight of hydrogen into the reduction tower for reduction; transferring the reduced material to a rectification kettle for further refining to obtain the product. The preparation method of 3-chloro-4-methylaniline provided by the invention effectively saves the use of raw materials and reasonably reduces energy c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com