Oil field scale inhibitor as well as preparation method and application thereof

A scale inhibitor and oilfield technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of loss of scale inhibitor effect, easy to be decomposed, low thermal stability of scale inhibitor, etc. Achieve good thermal stability and high calcium tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

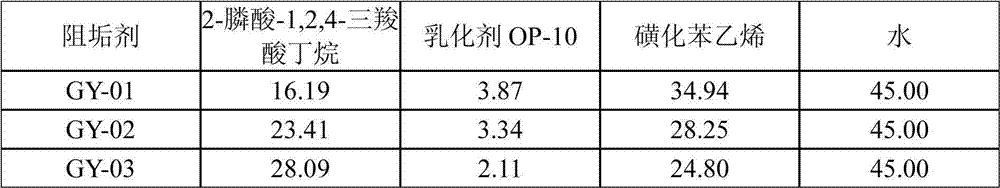

[0016] This example provides three different scale inhibitors, the composition of which is shown in Table 1.

[0017] These three antiscalants were prepared according to the following steps:

[0018] Heat water to 60°C, then add 2-phosphonic acid-1,2,4-tricarboxylic acid butane, sulfonated styrene and emulsifier OP-10 in sequence, and stir evenly to obtain scale inhibitor.

[0019] The composition of table 1 antiscalant composition (in terms of the gross weight of this antiscalant, unit is %)

[0020]

[0021] Embodiment 2 scale inhibitor performance test experiment

[0022] In this example, the heat stability and calcium tolerance of the scale inhibitor are tested.

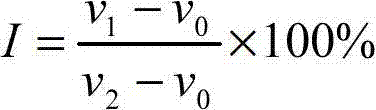

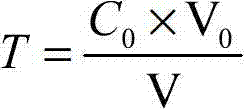

[0023] The thermal stability test method is: heat the scale inhibitor at 150°C for 72 hours, and measure the change of scale inhibition rate before and after heat treatment. -1993): In the water sample with a scale inhibitor concentration of 80mg / L, keep the temperature at 95°C for 25 hours, take it out, co...

Embodiment 3

[0032] Example 3 Scale inhibition performance evaluation experiment

[0033] In this example, the scale inhibition performance of the scale inhibitor was evaluated. The experimental water used in the scale inhibitor performance evaluation experiment was prepared with reference to the oilfield water quality characteristics to simulate oilfield water (see Table 3 for the specific composition), and the water used for the preparation was tap water.

[0034] Get 3 kinds of antiscalant GY-01, GY-02, GY-03 that embodiment 1 provides, evaluate antiscalant according to China petroleum and natural gas industry standard " performance evaluation method of antiscalant agent for oil field " (SY / T5673-1993) Scale inhibition performance (expressed as scale inhibition rate), according to "Evaluation Method of Corrosion Inhibitor Performance for Oilfield Produced Water" (SY / T5273-2000) to evaluate the corrosion inhibition performance of scale inhibitor (expressed as corrosion inhibition rate). ...

Embodiment 4

[0041] In this example, the performance of scale inhibitors in practical applications is tested: take the three scale inhibitors GY-01, GY-02, and GY-03 provided in Example 1, and mix them with hot water pipe network in an oil production plant in Liaohe Oilfield On-site evaluation of antiscalant performance, the specific operation is to mix the antiscalant into the hot water pipe network, and mix it with high-temperature oilfield water for transportation. The on-site working conditions are: water temperature 90°C, water pressure 1.1-1.8MPa, flow rate 150-210m 3 / d, the indicators of water quality analysis are shown in Table 5, the dosage of scale inhibitor is 80mg / L, and the test time is 2 months.

[0042] Table 5 Water quality analysis indicators of on-site water quality

[0043] indicators

Contentmg / L

total residue

2065.96

TDS

1892.23

Petro

31.01

Cl -

361.54

SO 4 2-

30.58

Ca 2+ Har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com