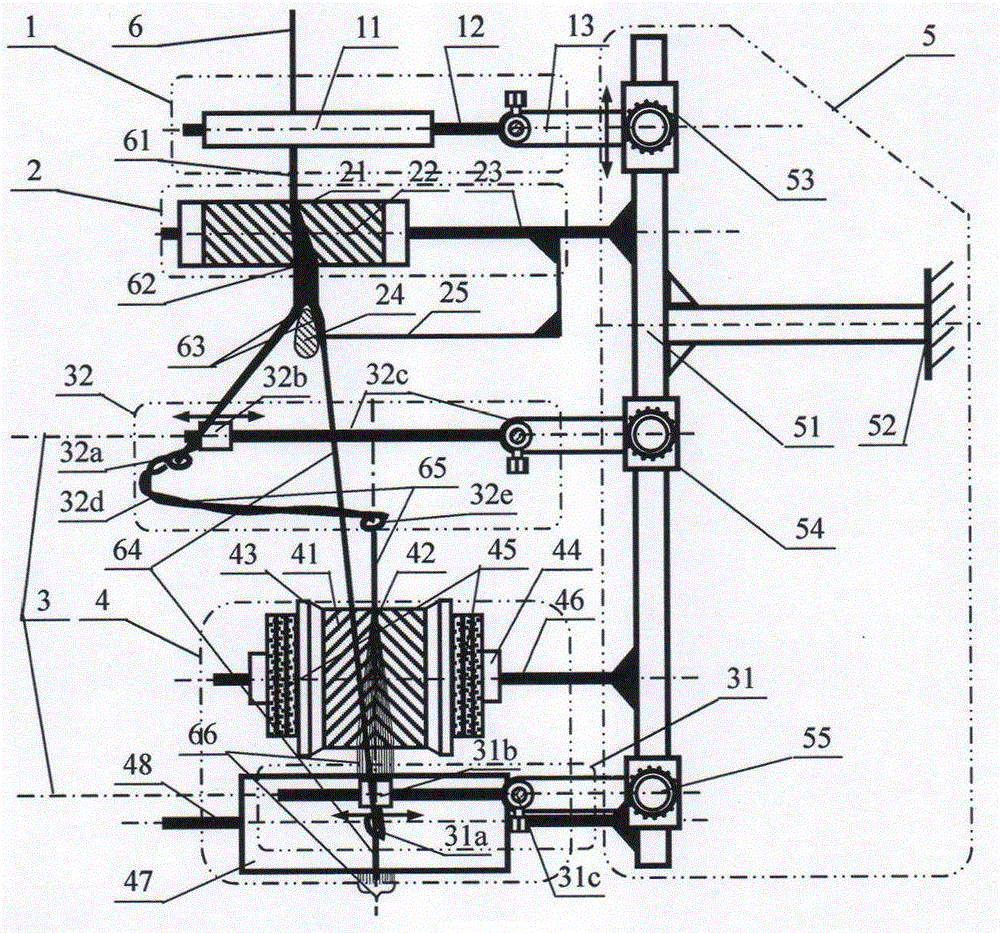

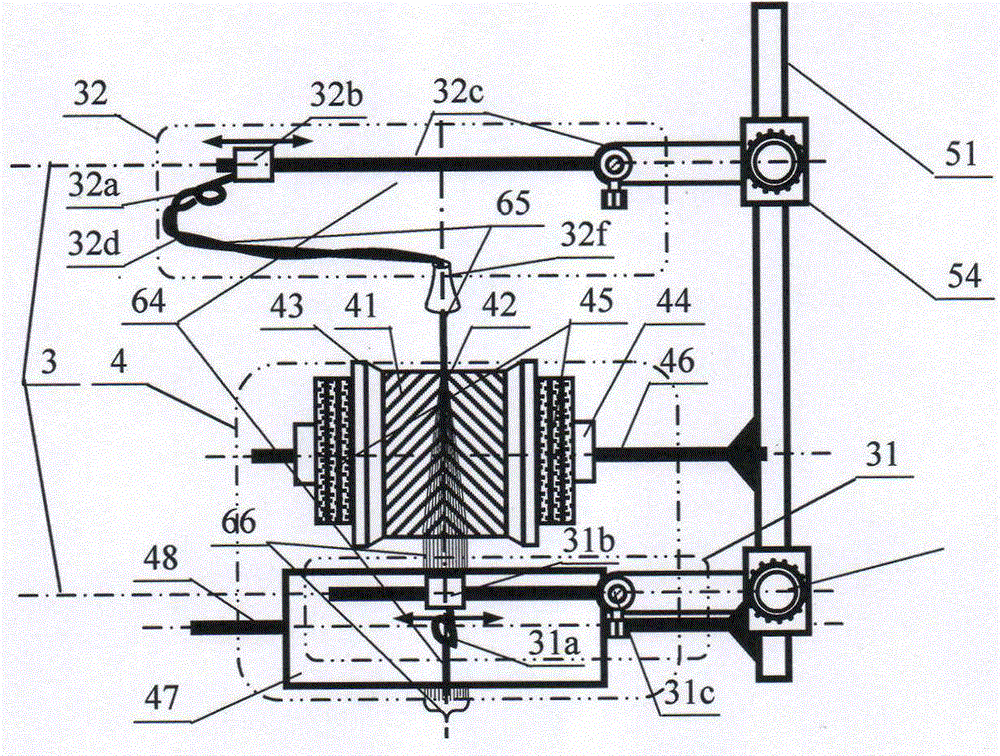

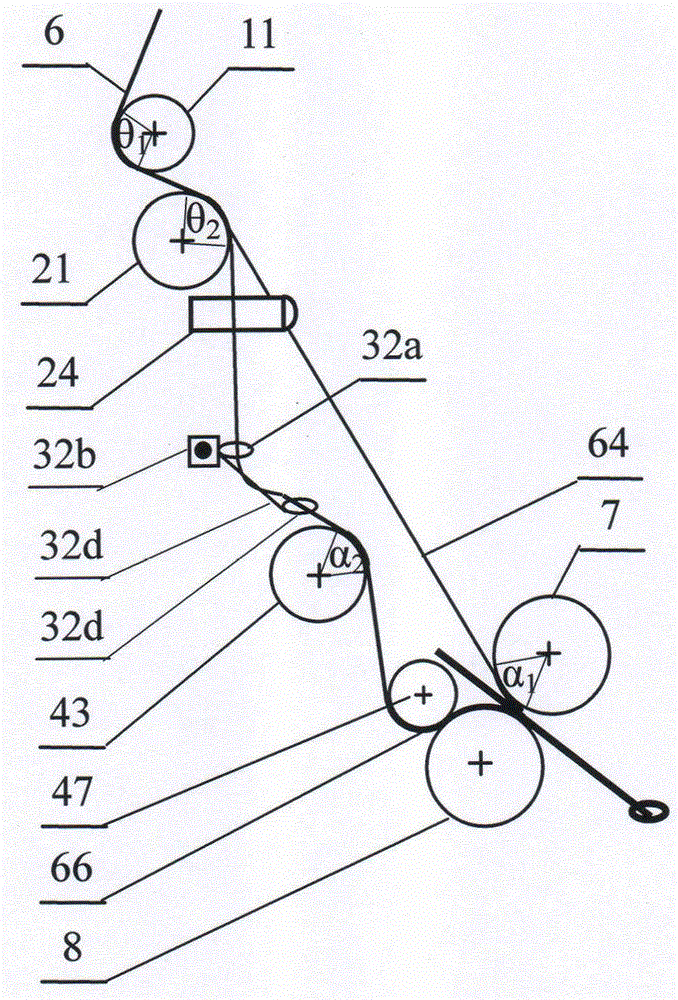

Re-expanding and clustering compound filament spreading device, method and application of asymmetric spreading and splitting

An asymmetric, yarn spreader technology, used in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of poor spinnability, unsuitable for short and weak fibers and high branching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Spinning recycled cotton / viscose filament composite yarn

[0043] Using the re-expansion and clustering composite filament spreader for asymmetric spreading and splitting of the present invention, the viscose filament bundle is split and spread into tow and silk net according to the above-mentioned splitting and spreading method, and then The front roller nip is twisted and compounded with recycled cotton fiber strands to form a smooth reinforced composite yarn. The specific process parameters are shown in the table below. Since the core / network splitting mass ratio is 1:1, the theoretical occupancy of the surface silk screen is 1 / 2 of the composite ratio, that is, 14.405%. The content of the measured surface viscose filament is 13.0%. can be effectively displayed. 13.0% of the viscose filaments spun into split yarns and wrapping the smooth composite yarns of noil staple fibers, the yarn hairiness index, twist angle, breaking strength, elongation at break...

Embodiment 2

[0044] Embodiment 2: spinning kapok / polyester filament composite yarn

[0045] Using the re-spreading and clustering composite spreader for asymmetric spreading and splitting of the present invention, the polyester filament bundles are split and spread into tows and screens according to the above-mentioned splitting and spreading method, and then The kapok is twisted and composited at the nip of the roller to form a smooth reinforced composite yarn. The specific process parameters are shown in the table below. Since the core / network splitting mass ratio is 3:7, the theoretical occupancy of the surface screen mesh is 7 / 10 of the composite ratio, that is, 18.98%. The measured surface polyester filament content is 17.73%, and the characteristics of kapok fiber can be displayed. And it can effectively prevent chipping and reduce hairiness. The spun polyester filament split yarn is a smooth composite yarn wrapped with kapok fiber strands. The hairiness index, twist angle, breaking...

Embodiment 3

[0046] Embodiment 3: Reuse cashmere / silk composite yarn

[0047] Using the re-expansion and clustering composite silk spreader for asymmetric spreading and splitting of the present invention, the silk is split and spread into tows and silk nets according to the above-mentioned splitting and spreading method, and then the front roller nips Twisting and compounding with recycled cashmere fiber strands to form a smooth reinforced composite yarn. The specific process parameters are shown in the table below. Since the core / network splitting mass ratio is 9:1, the theoretical occupancy of the surface silk mesh is 1 / 10 of the composite ratio, that is, 1.688%. The measured surface silk content is 0.54%, and the characteristics of cashmere fibers can be fully displayed. , almost no filaments, and can effectively reduce hairiness. The spun silk split yarn is wrapped with cashmere staple fiber and is wrapped with smooth and clean composite yarn. The hairiness index, twist angle, breakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com