Button translation and rotation improvement mechanism for button sewing machine tool

A technology for machine tools and buttons, applied in sewing machine components, control devices for sewing machines, textiles and papermaking, etc., can solve the problems of not smooth action connection, difficulty in debugging and maintenance, and easy crash of the buttoning machine, so as to avoid instability, Compact structure, the effect of reducing the difficulty of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

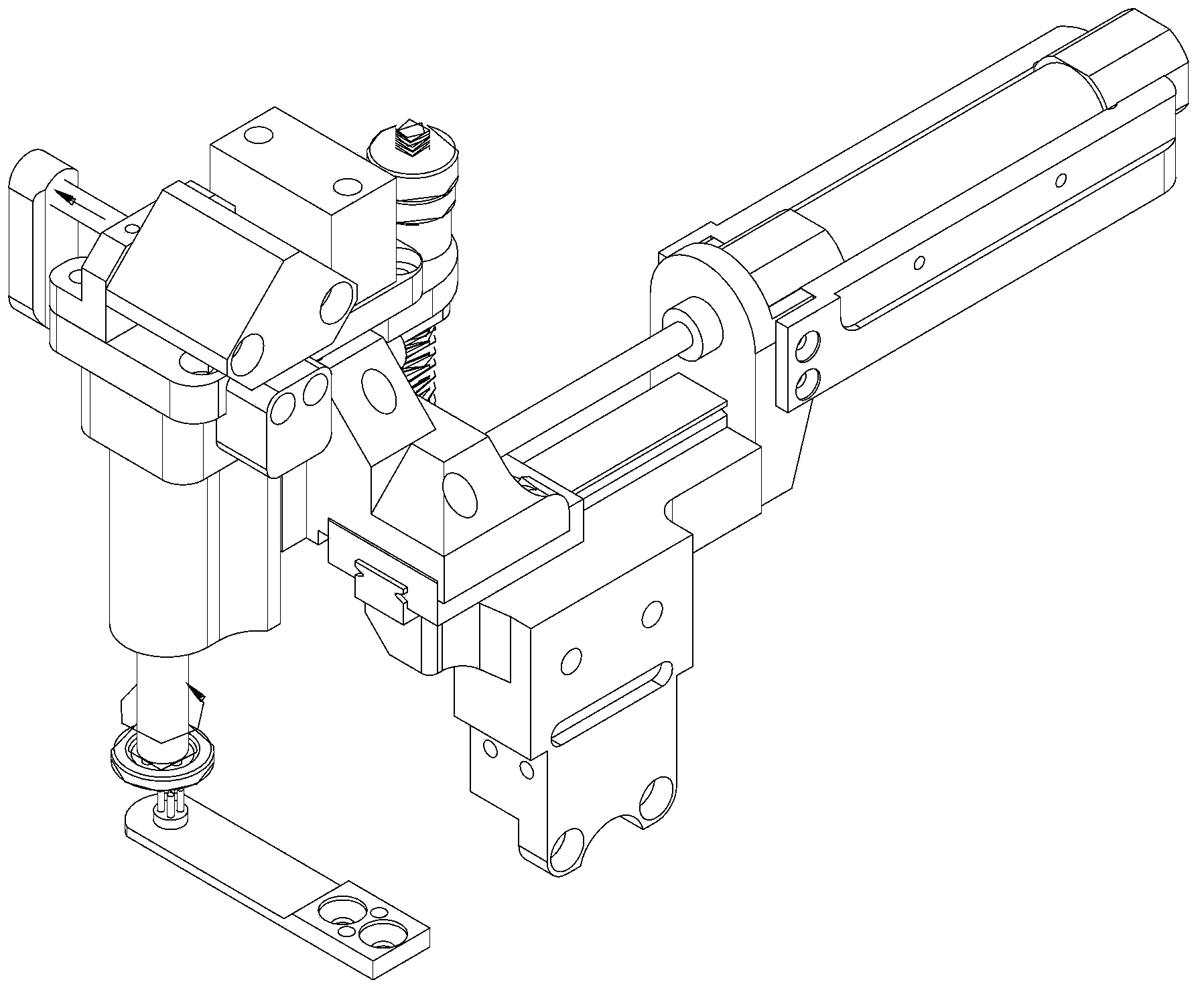

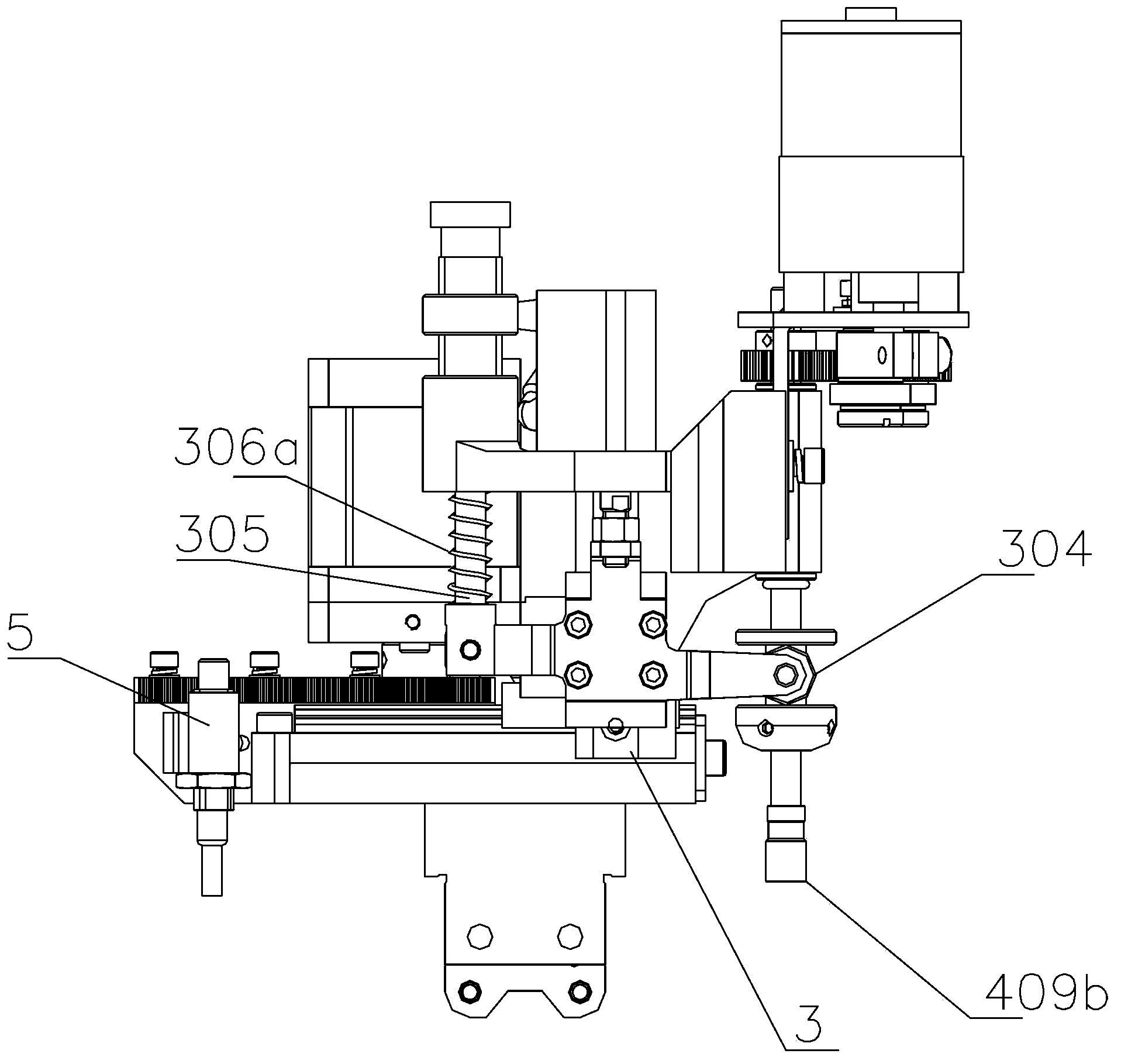

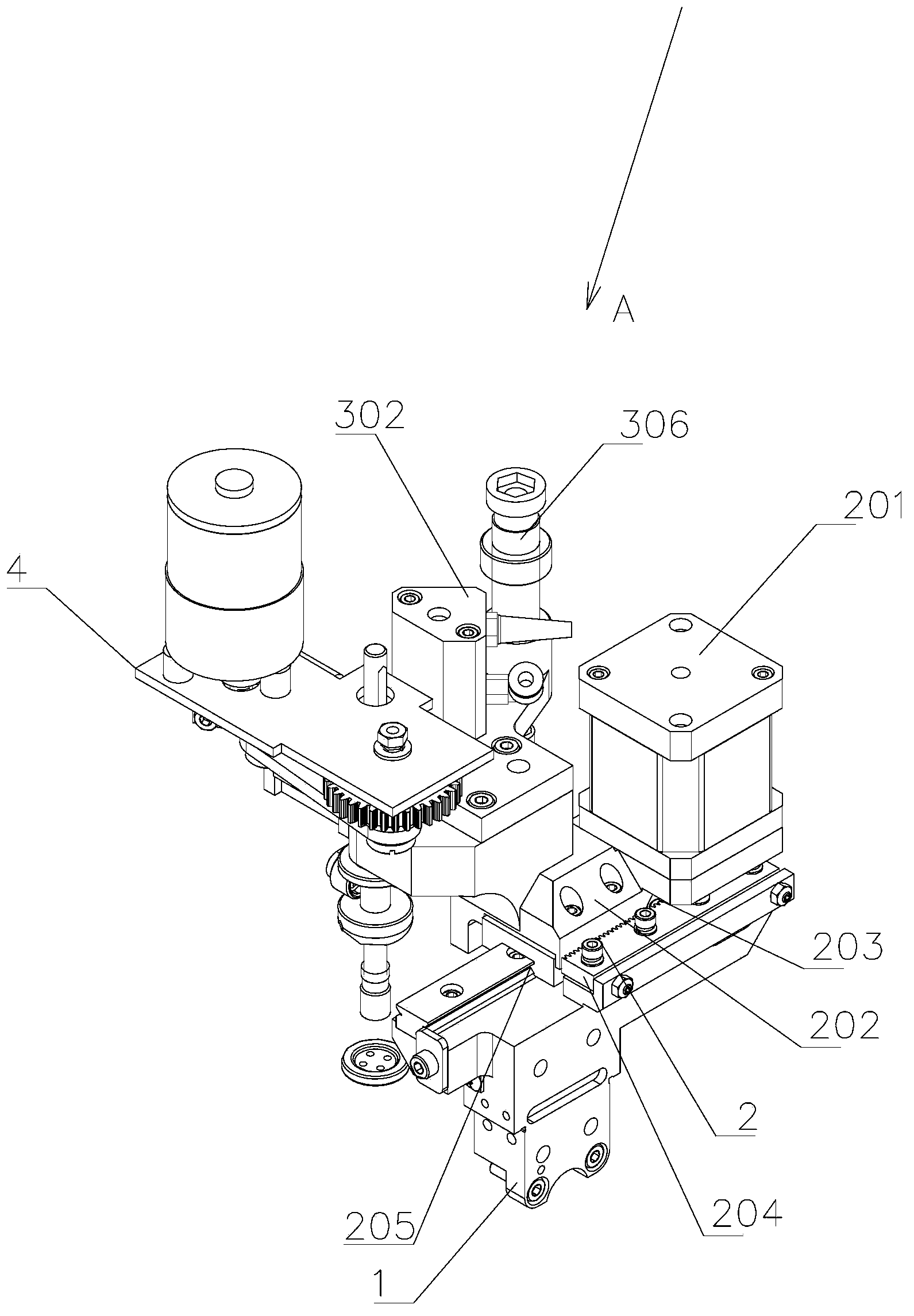

[0019] as attached figure 2 , 3 As shown in and 4, an improved mechanism for button translation and rotation of a button sewing machine, including a bracket base 1, a translation component 2 is mounted on the bracket base 1, a vertical movement component 3 is mounted on the translation component 2, a vertical movement component 3 and a rotation component 4 connect.

[0020] Wherein, the translation assembly 2 includes a translation stepping motor 201, and the translation stepping motor 201 is installed vertically downward on the right side of the upper surface of the stepping base 202, and a gear 203 is installed on the output shaft of the translation stepping motor 201, and the gear 203 and The rack 204 fixedly installed on the bracket seat 1 is engaged, the step base 202 is installed on the translation linear guide rail slider assembly 205 and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com