Gluing-free floor split block

A floor and block technology, applied in the direction of floors, buildings, building structures, etc., can solve problems such as deformation, buckling, and displacement, and achieve the effect of reducing consumption, avoiding deformation, and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

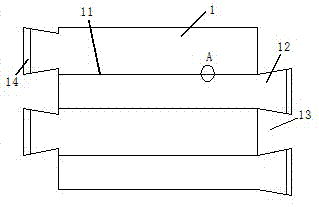

[0035] Such as figure 1 , 2 , 3, the glue-free floor block disclosed in this embodiment includes four floor strips 1, and each floor strip includes a bottom layer and a surface layer, and the bottom layer of the plank blocks everywhere is connected, and there are gaps between the surface layers. There are slits 11, and the ends of the same side of the alternate floor blocks are provided with tenons 12 in an isosceles trapezoidal shape, a tenon groove 13 matching the tenons is formed between the tenons, and a slope 14 is provided on the lower bottom of the tenons. The lower base of the tongue and groove is provided with an inverted slope that can be matched with the inclined surface.

[0036] In the glue-free floor block of this embodiment, the adjacent floor blocks are of different widths, and in two adjacent floor blocks, the tenon on the first floor block is the same as that on the second floor block. The tenons on the first floor plank are the same size, and the tenon on ...

Embodiment 2

[0045] The glue-free floor block structure disclosed in this embodiment is similar to Embodiment 1, but there are the following differences with Embodiment 1: it includes two floor panels, and each floor panel includes, in addition to the bottom layer and the surface layer, A flexible layer and a fiberglass cloth layer placed on top of the base layer, and a pattern layer placed on top of the top layer. The floor board consists of bottom layer, surface layer, soft layer, glass fiber cloth layer and pattern layer to form a five-layer structure. The bottom layer and the surface layer are tightly combined by pressing. In this embodiment, the bottom layer is a plastic layer, and the surface layer is a wood layer. In this embodiment, the anti-slip pattern is a grid anti-slip pattern, and the lattice of the mesh anti-slip pattern is a regular hexagonal lattice with a groove in the center, and the groove is a groove with a regular polygonal cross section, and the mesh only Openings ...

Embodiment 3

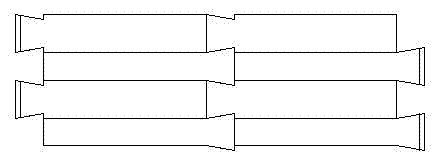

[0049]The glue-free floor block structure disclosed in this embodiment is similar to Embodiment 1, but there are the following differences with Embodiment 1: it includes six floor bars, and each floor bar includes, in addition to the bottom layer and the surface layer, Pattern layer set on top of the finish layer. The bottom layer and the surface layer are closely combined in a composite form, and the bottom layer in this embodiment includes a flexible layer, a glass fiber cloth layer and an iron powder layer, and the floor plank consists of a three-layer structure consisting of the bottom layer, surface layer and pattern layer. And in this embodiment, the tenons on the floor boards are in the shape of a right-angled trapezoid, and a tenon groove matching the tenons is formed between the tenons.

[0050] The anti-slip lines provided on the bottom surface of the bottom layer are stripes.

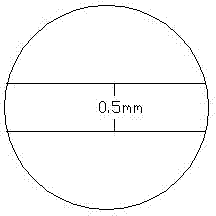

[0051] In this embodiment, the width of the slit is 0.1 mm, the inclination angle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com