Steam turbine

A technology of steam turbines and steam turbines, which is applied to mechanical equipment, engine components, machines/engines, etc. It can solve the problems of low mechanical efficiency, poor tightness between cylinders and moving blade cascades, etc., and achieve high mechanical efficiency, light weight, and strong tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

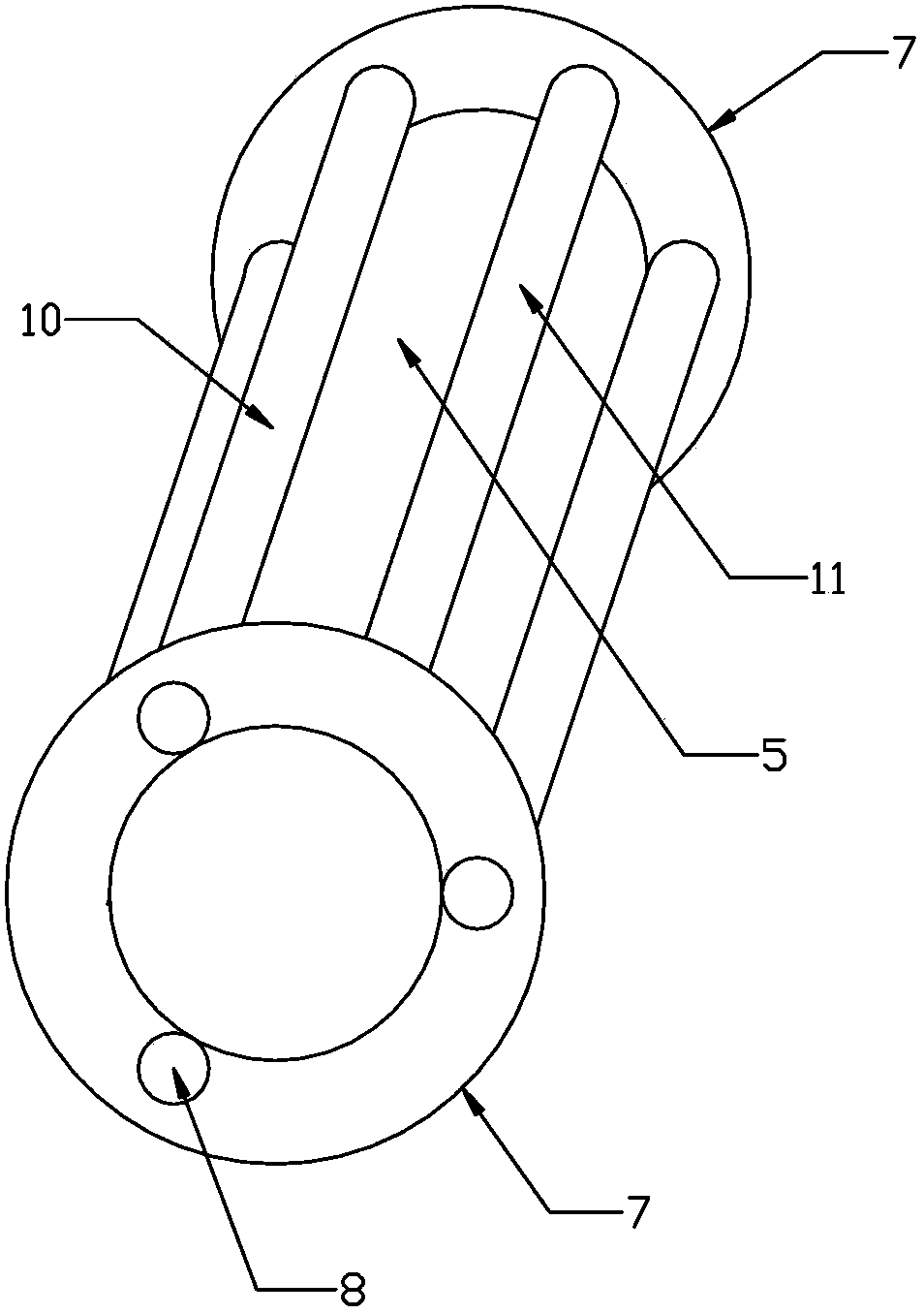

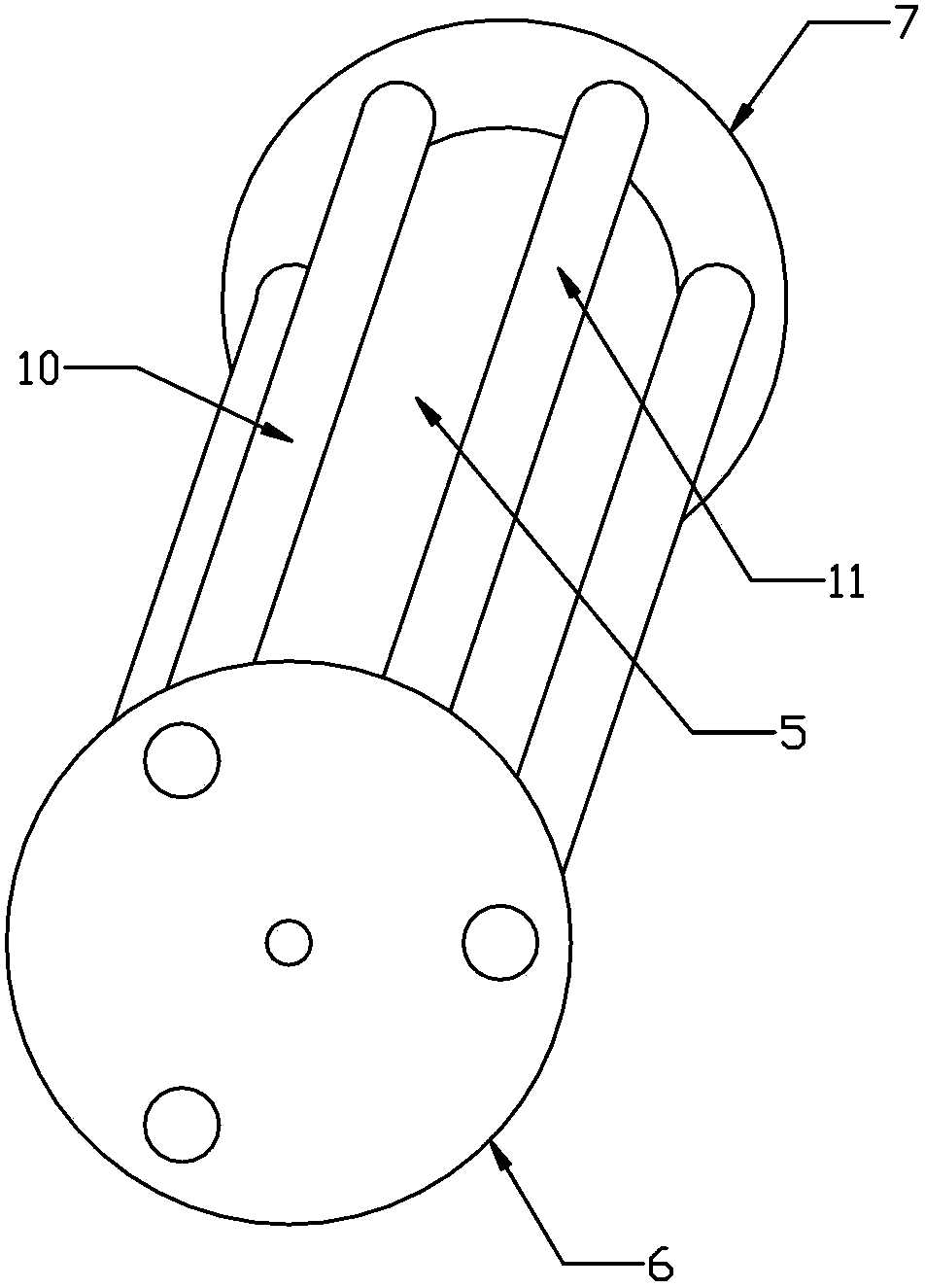

[0034] Such as Figure 1-7 As shown, a steam turbine according to an embodiment of the present invention at least includes an intake bin 1, a cylinder block 2 and an exhaust bin 3, wherein;

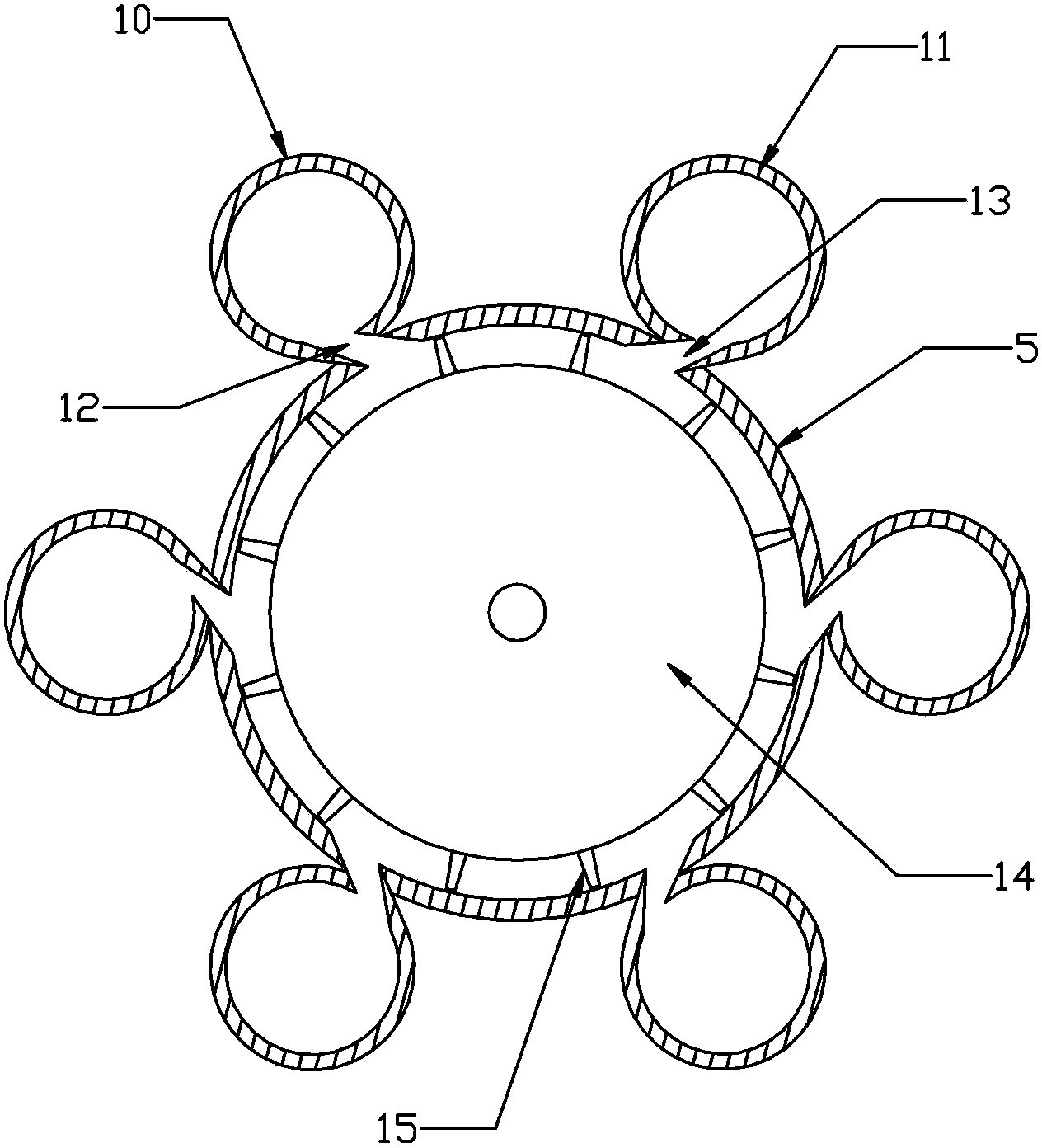

[0035] The cylinder block 2 includes a cylinder and a steam wheel 4. The cylinder is composed of a circular cylinder tube 5 and a cylinder head 6 placed at both ends of the cylinder tube. Both ends of the cylinder tube 5 are provided with bottom outer rings 7 , One of the bottom outer rings is provided with an air inlet 8, and the other bottom outer ring is provided with an exhaust 9; the outer periphery of the cylinder 5 and the inner side of the two bottom outer rings are connected An even-numbered air chamber, the air chamber includes an intake chamber 10 and an exhaust chamber 11, and the intake chamber and the exhaust chamber are alternately distributed; one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com