Blade of horizontal axis WTGS and forming method and equipment thereof

A technology for wind turbines and wind turbines, which is applied to wind turbines, wind turbines in the same direction as the wind, and wind power generation, etc., can solve problems such as poor compression stability, airfoil aerodynamic performance at the expense of aerodynamic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

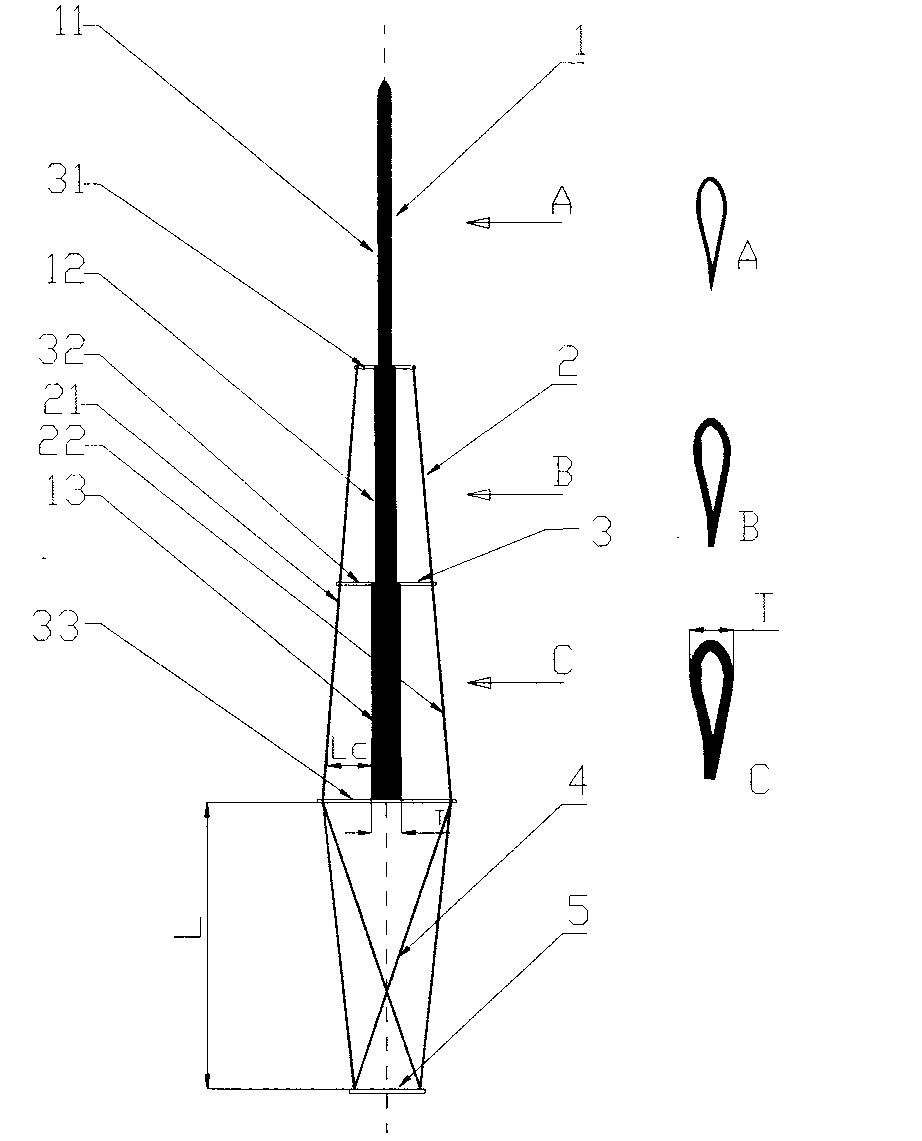

[0032] Figure 5 It is an equipment system for pultrusion forming such constant airfoil section blade segments.

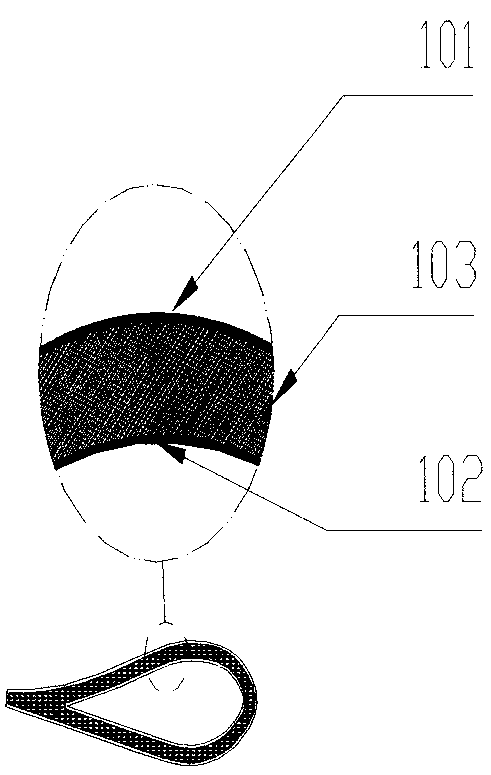

[0033] figure 2 In, 101-airfoil shell outer skin, 102-airfoil shell inner skin, 103-airfoil shell core structure

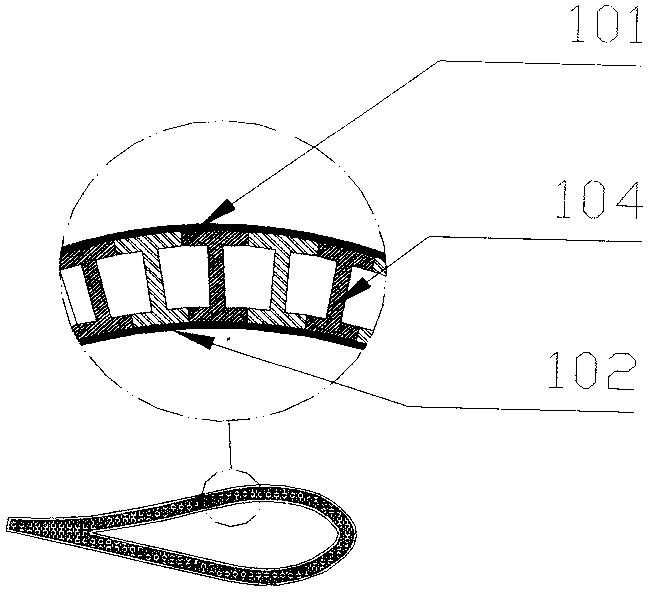

[0034] image 3 In, 101-airfoil shell outer skin, 102-airfoil shell inner skin, 104-airfoil shell "I" core structure

[0035] Figure 4 Middle, 101-airfoil shell outer skin, 102-airfoil shell inner skin, 105-airfoil shell "back" core structure

[0036] Figure 5 Among them, 501-upper pultrusion equipment group, 502-lower pultrusion equipment, 503-post-processing equipment, 511-cavity external mold, 512-cavity internal mold, 513-cantilever support, 51-fiber yarn, 52-resin Groove, 53-fiber cloth, 54-core profile, 55-cavity, 56-heating and curing device, 57-traction mechanism, 58-synchronous roughening device, 59-synchronous spraying device, 60-cutting device, 104-wing Type shell "I" type core structure, 1-aerodynamic airfoil.

[0037] According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com