Oil and gas mixed damper

An oil-gas mixing and damper technology, which is applied to gas-liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve the problem that automatic return cannot be realized, and achieve the effect of easy return and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

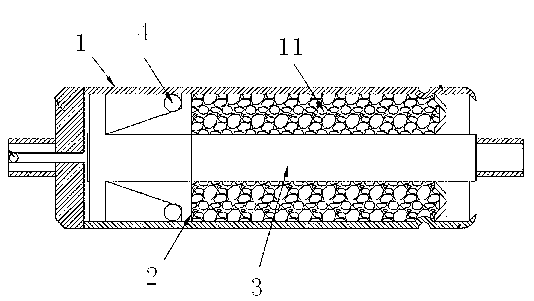

[0010] An oil-gas mixing damper according to the present invention comprises a pipe body 1, a hydraulic oil 11 is arranged in the pipe body, a piston 2 and a piston rod 3 are arranged in the pipe body 1, and one end of the piston rod 3 is connected to the piston 2, The other end protrudes out of the pipe body 1; the bottom end of the piston 2 is a 45-degree oblique groove structure, and flow holes are arranged on the front and rear end faces of the piston 2, and the diameter of the flow hole at the rear end of the piston is larger than that at the front end of the piston. An O-ring 4 is arranged in the oblique groove at the rear end of the piston 2 .

[0011] When in use, the front end of the piston is a small flow hole. When the force is compressed inward, the O-ring moves upwards according to the movement track, and closes with the upper end of the oblique angle at the rear end of the piston and the inner wall of the tube, so that when the oil is discharged, it will The over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com