Pipeline freezing rust scale layer structure sampling method

A layered structure and pipeline technology, applied in the field of sampling, can solve the problems of unable to guarantee the quality of sampling, destroy the layered structure of pipeline rust and scale, etc., and achieve the effect of convenient operation, high feasibility and large air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

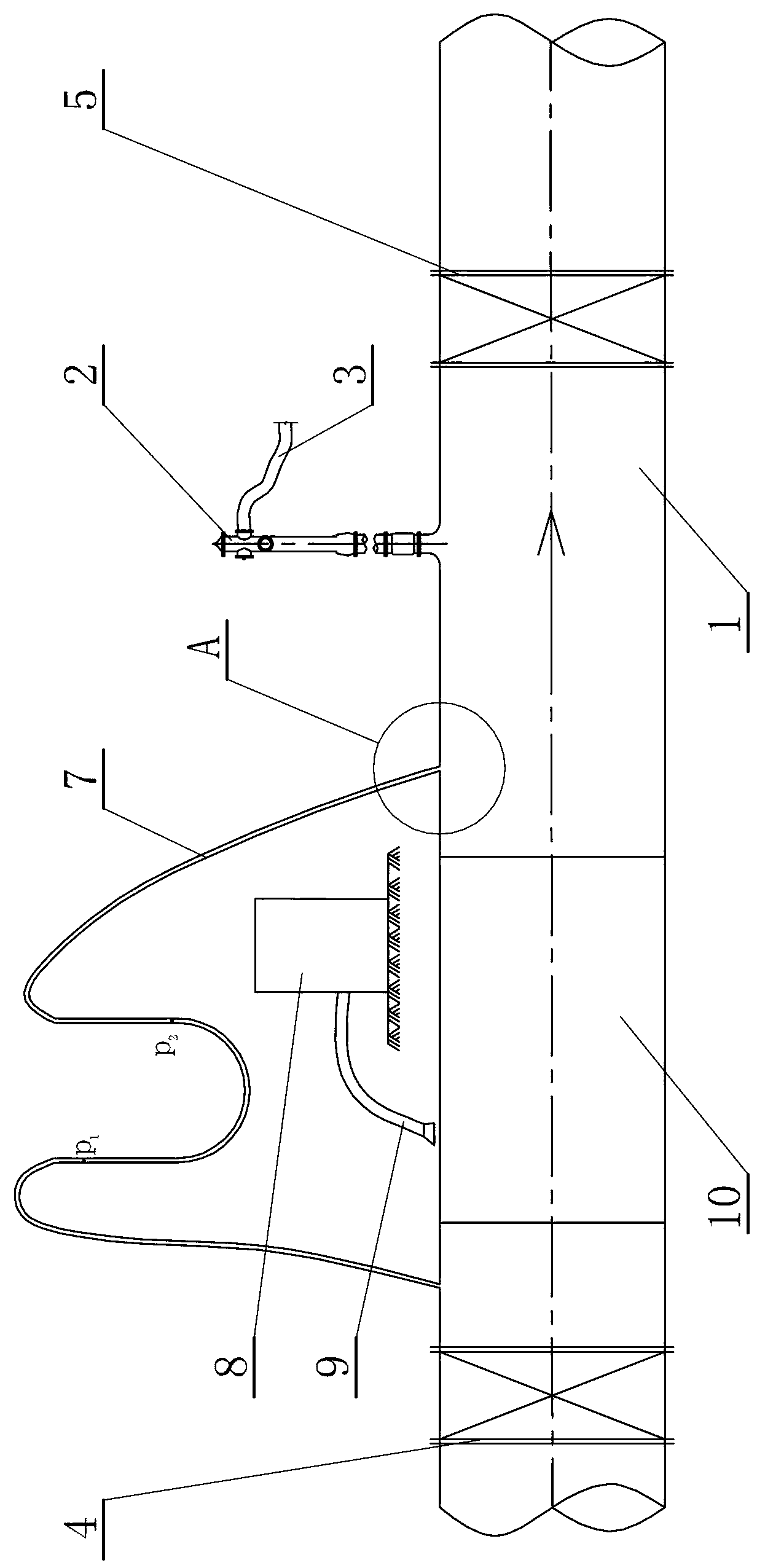

[0016] Specific implementation mode one: combine figure 1 and figure 2 Describe this implementation mode, this implementation mode comprises the following steps:

[0017] Step 1: Sampling point positioning process:

[0018] First select the stable water supply pipeline 1 as the sampling object, arbitrarily select a fire hydrant 2 on the stable water supply pipeline 1 as the sampling reference point;

[0019] Step 2: Auxiliary equipment installation and positioning process:

[0020] After the sampling point positioning process is completed, firstly, the fire hydrant 2 is fixedly connected with a drain hose 3, and then an upstream valve 4 and a downstream valve 5 are respectively installed at the front and rear ends of the water supply pipeline 1 where the fire hydrant 2 is located, and then Two through holes 6 are processed on the water supply pipe 1 between the fire hydrant 2 and the upstream valve 4, and the two ends of the U-shaped rubber hose 7 pass through the two thro...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, the length of the sampling pipe 10 in this embodiment is 0.3-0.8 m. Other methods and steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 and figure 2 Describe this implementation mode, step 1 of this implementation mode: sampling point positioning process:

[0027] First select the stable water supply pipeline 1 as the sampling object, arbitrarily select a fire hydrant 2 on the stable water supply pipeline 1 as the sampling reference point;

[0028] Step 2: Auxiliary equipment installation and positioning process:

[0029] After the sampling point positioning process is completed, firstly, the fire hydrant 2 is fixedly connected with a drain hose 3, and then an upstream valve 4 and a downstream valve 5 are respectively installed at the front and rear ends of the water supply pipeline 1 where the fire hydrant 2 is located, and then Two through holes 6 are processed on the water supply pipe 1 between the fire hydrant 2 and the upstream valve 4, and the two ends of the U-shaped rubber hose 7 pass through the two through holes 6 to communicate with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com