Permanent magnet piston motor

A piston, permanent magnet technology, applied in motors, electric vehicles, electrical components, etc., can solve problems such as high manufacturing costs and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

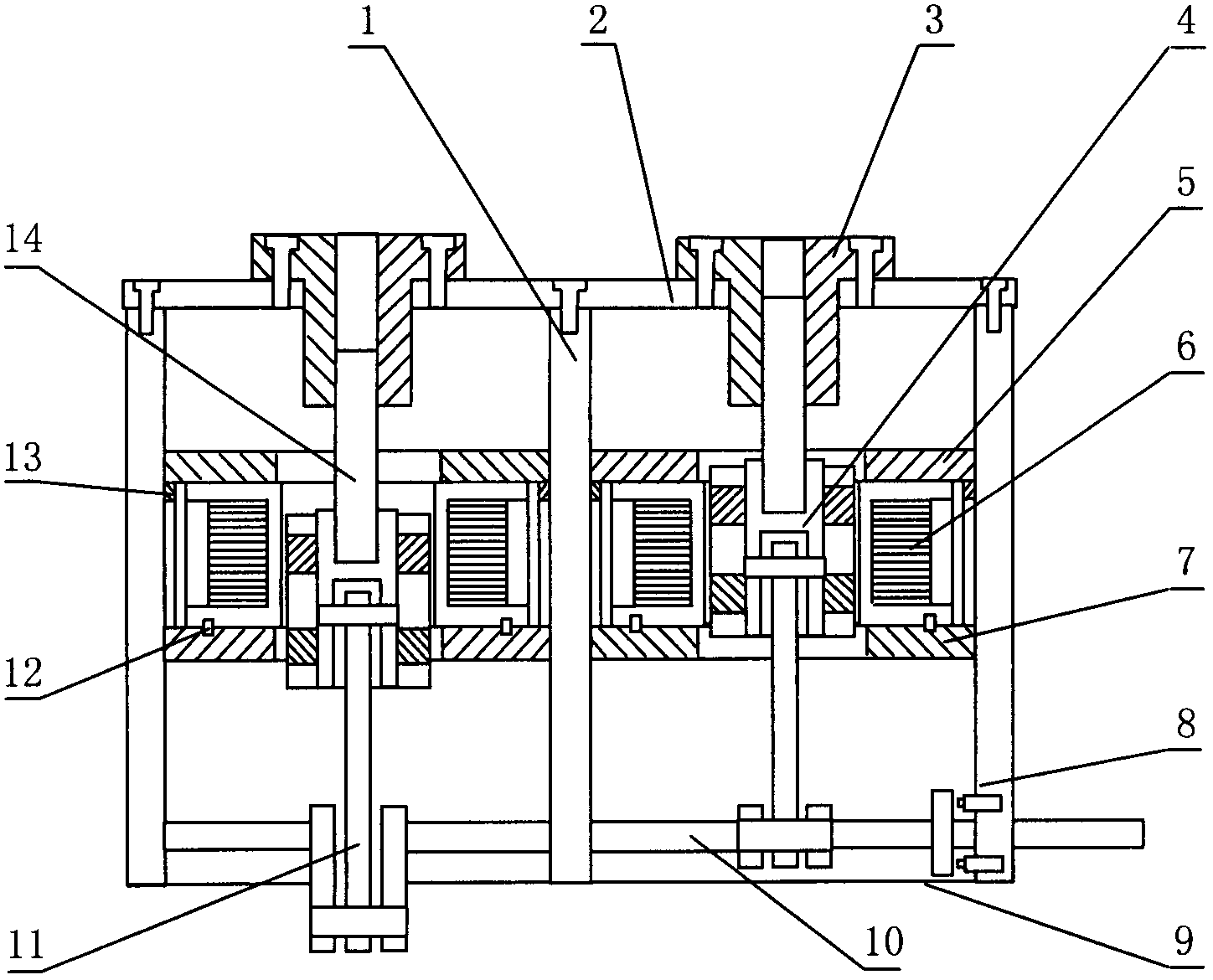

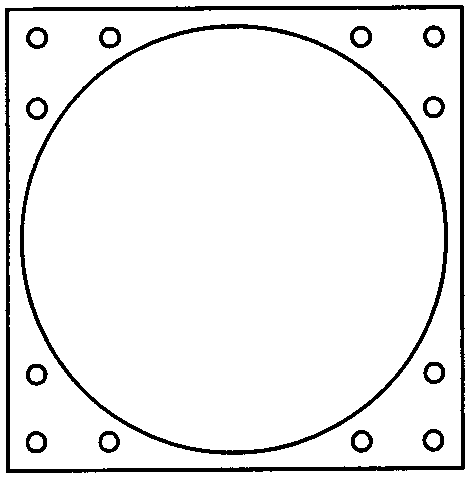

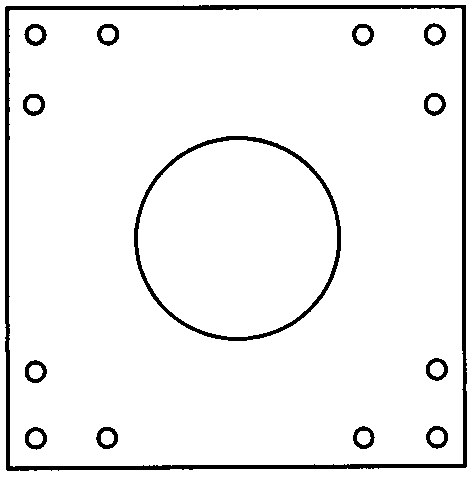

[0025] The present invention consists of a casing 1, an upper cover 2, a linear bearing 3, a permanent magnet piston 4, a limit plate 5, a coil cylinder body 6, a bottom plate 7, a Hall I 8, a signal plate 9, a crankshaft 10, a connecting rod 11, a positioning The left-right symmetrical structure composed of the main parts such as the pin 12, the fixing plate 13, and the sliding rod 14 is assembled in the following manner: first, the bottom plate 7 and the retaining plate 13 are welded into a whole with the casing 1, and the lower half of the positioning pin 12 is embedded In the pin hole of the bottom plate 7, put the positioning hole of the coil cylinder 6 downward into the upper half of the positioning pin 12, so that the coil cylinder 6 is positioned and installed on the bottom plate 7, and then the limit plate 5 and the coil cylinder The upper surface of 6 is bolted to the positioning plate 13 after being closely matched, and the coil wiring A1, A2, B1, B2 is drawn out; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com