Weld structure having resistance to brittle crack propagation

A structural and expansive technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of reduced strength of welded structures and long extension of brittle cracks, so as to prevent large-scale damage and high The effects of safety and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

[0054]

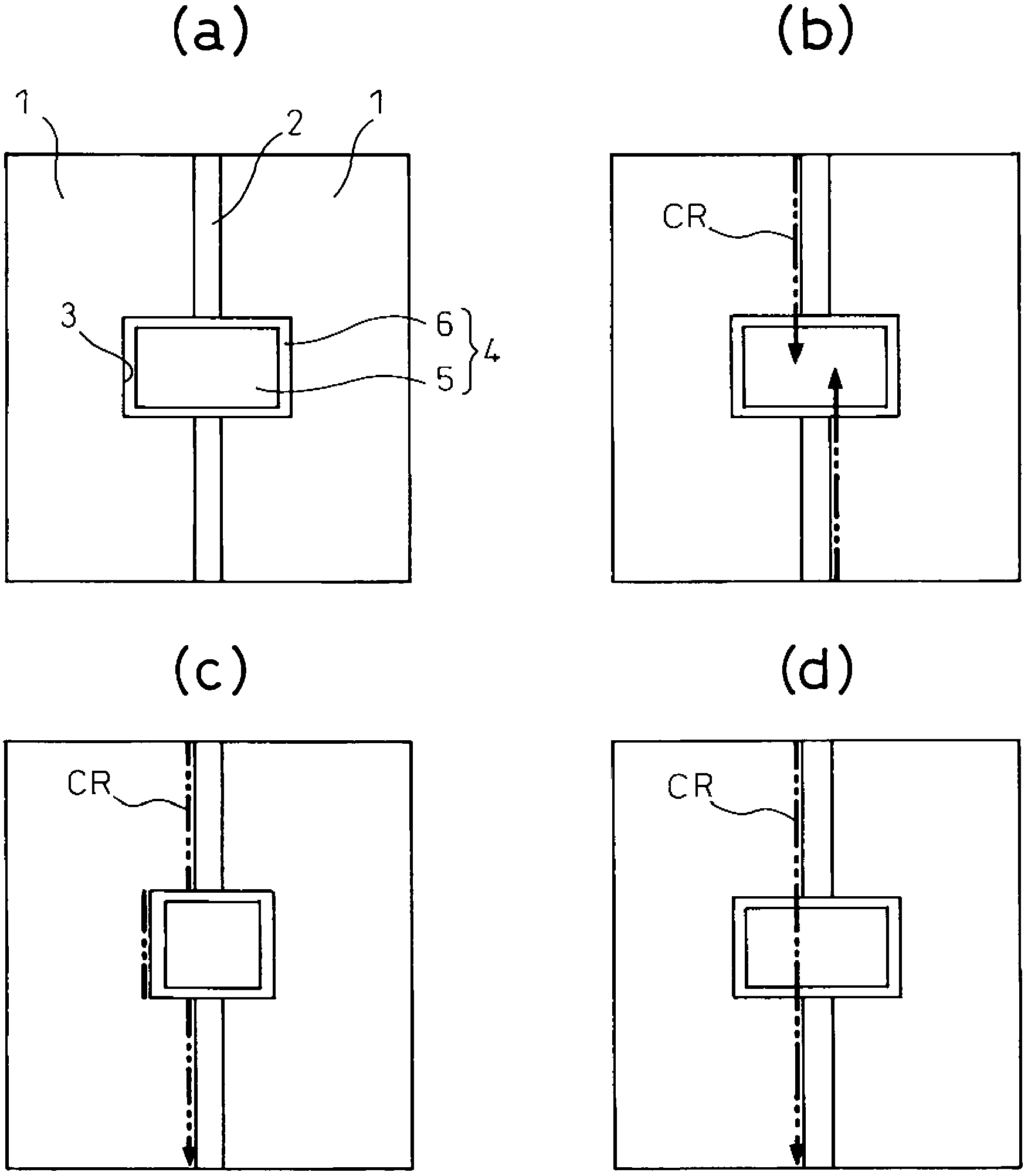

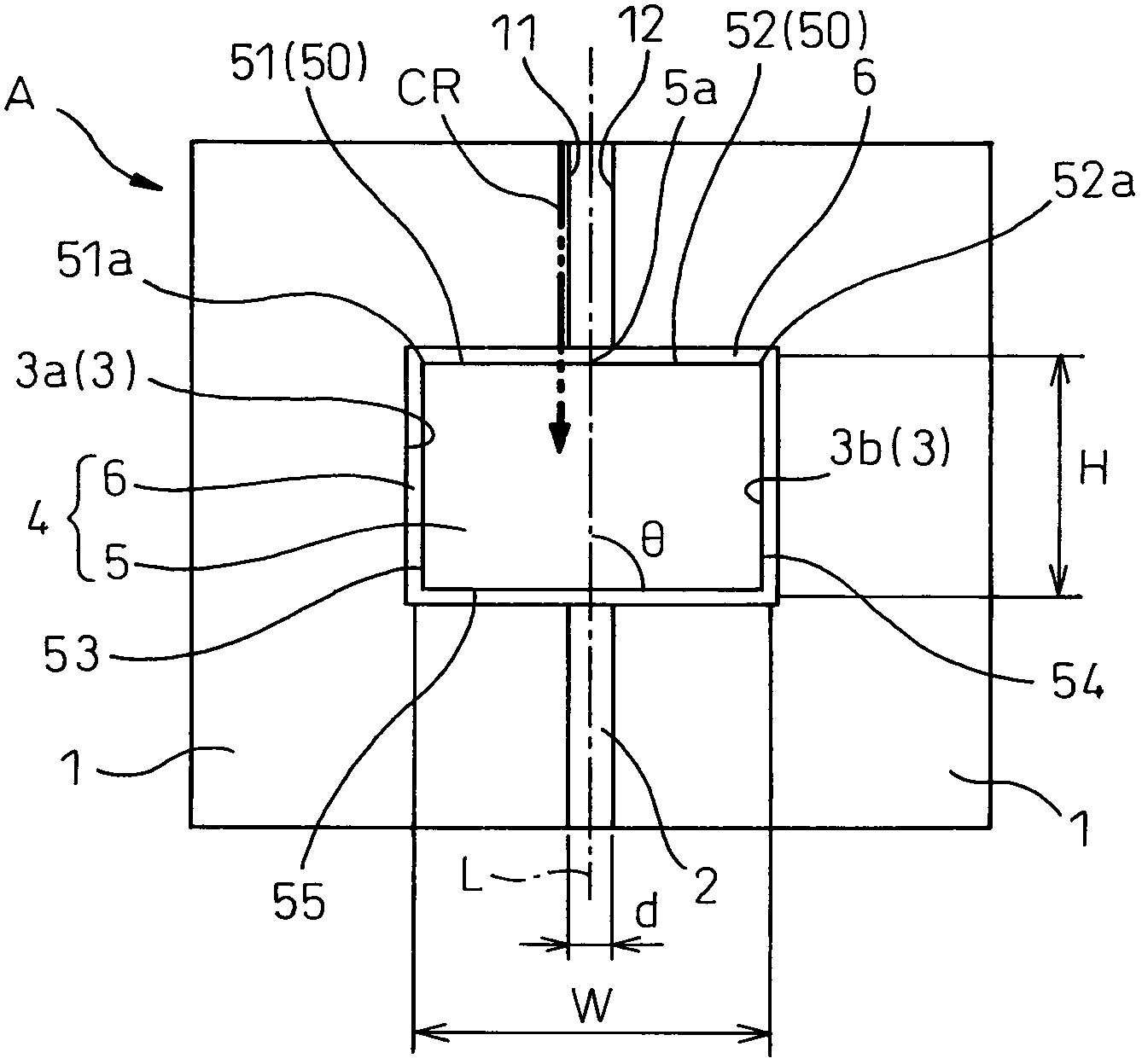

[0055] The first embodiment is, if figure 2 As shown, an example of the case where the steel plate welded joint 2 is formed by butt welding the steel plates 1 and 1 will be described below by referring to the form applied to the joint as a welded structure A.

[0056] In the welded structure A, the anti-crack control part 4 is provided at least one place of the steel plate welded joint where crack generation and propagation are expected to occur when a large destructive energy due to collision, earthquake, etc. is applied.

[0057] The anti-crack control part 4 is provided in a manner to penetrate the steel plate 1, including: the brittle crack propagation stop characteristic Kca is 6000N / mm 1.5 A crack arresting member 5 made of the above steel materials, and a crack arresting welded joint 6 formed by butt welding the crack arresting member 5 to the steel plate 1 .

[0058] The crack arresting member 5 is formed such that the outer edge portions 50 (51, 52) respe...

no. 2 Embodiment approach ]

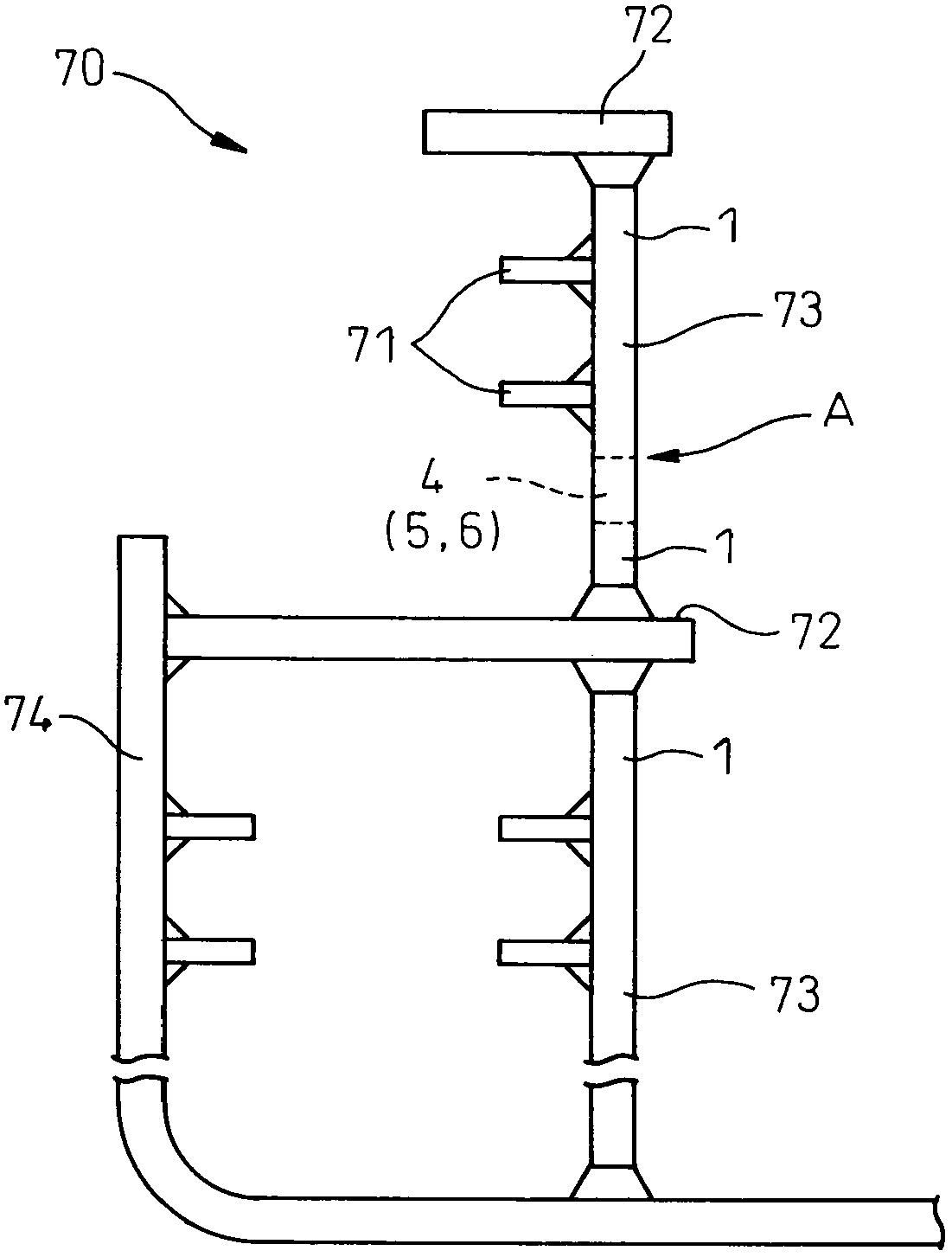

[0122] Hereinafter, for the welded structure B as the second embodiment of the present invention, mainly refer to Figure 4 to elaborate. In addition, in the following description, the same code|symbol is attached|subjected to the structure common to the welded structure A of 1st Embodiment mentioned above, and the detailed description is abbreviate|omitted.

[0123] The welded structure B is an example of a case where the steel plates to be butt-welded are formed by butt-welding a plurality of small steel plates.

[0124] That is, if Figure 4 As shown, the steel plate 10 is at least two or more small steel plates arranged in the longitudinal direction of the steel plate welded joint 20 (refer to Figure 4 Marks 21 to 24 in ) are formed by butt welding, and the crack resistance control part 4 is provided in the steel plate welded joint 20 formed by butt welding the steel plates 10 and 10 .

[0125] Between the small steel plates 21, 22, by butt welding, small steel plate w...

Embodiment

[0140] [Manufacture of welded structures]

[0141] First, in the steelmaking process, deoxidation, desulfurization and chemical composition of molten steel were controlled, and ingots having chemical compositions shown in Table 1 below were produced by continuous casting. Then, the ingot was reheated and hot-rolled under the manufacturing conditions in accordance with the standard manufacturing conditions of the Nippon Kaiji Kaisha (NK) standard rolled steel materials for ship hulls KA32, KA36, and KA40, thereby manufacturing steel pipes of various thicknesses. steel plate. Furthermore, various heat treatments were performed on the steel sheet, and the conditions at this time were controlled, thereby properly adjusting the brittle crack growth stop characteristic Kca (N / mm 1.5 ) for various values.

[0142] The ESSO test (brittle crack growth stop test) piece with a size of 500mm×500mm×plate thickness is appropriately prepared from the manufactured steel plate, and the Kca c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com