Integrated automatic ash discharge pulse bag filter

A technology of bag dust collector and dust collector, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of large damage, low degree of automation, and manual cleaning of bag dust collectors, etc. Achieve the effects of reducing operation and maintenance costs, high degree of automation, and improving dust collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

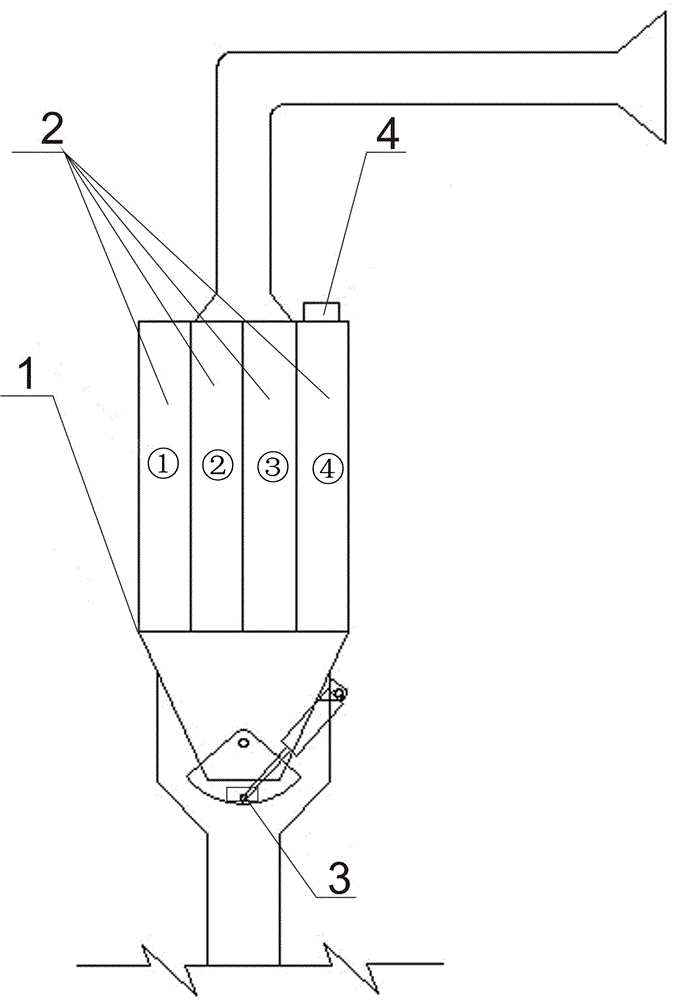

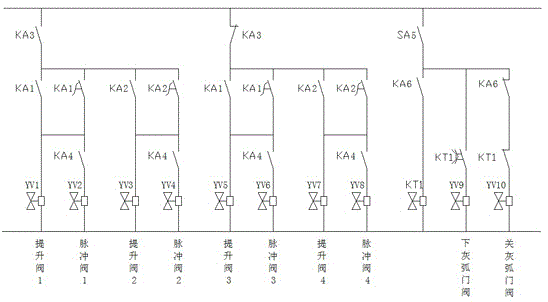

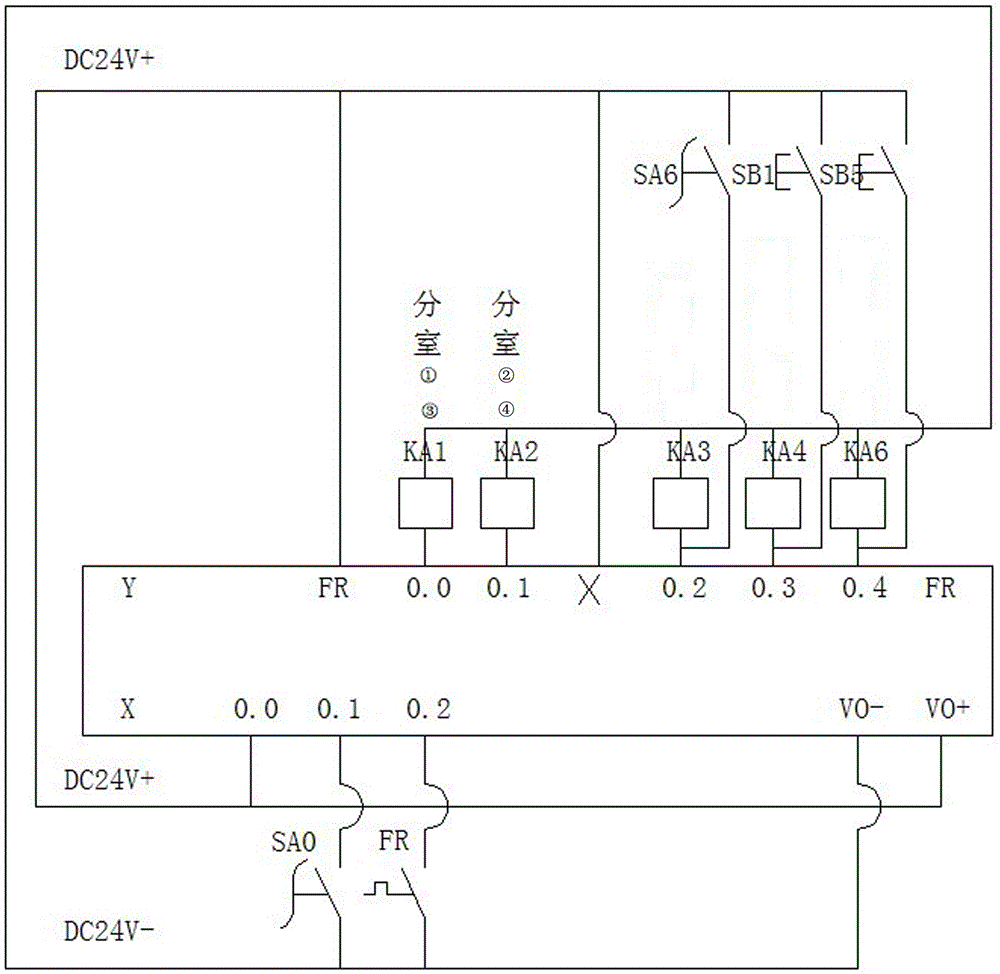

[0034] The integrated automatic ash discharge pulse bag dust collector of the present invention has four sub-chambers 2 in total, namely: sub-chamber ①, sub-chamber ②, sub-chamber ③, and sub-chamber ④, wherein each sub-chamber 2 has a poppet valve and a pulse valve , a total of 8 control valves. The classification of the control valve is shown in the table, adding a group of load cell 3 control contacts.

[0035] Table 1: Control Valve Classification Table

[0036]

[0037] Table 2: Switch and relay control table

[0038]

[0039] work process:

[0040] First of all, it is grouped, and its 8 control valves are divided into the first control valve group and the second control valve group. The control valves YV1-YV4 form the first control valve group, and the control valves YV5-YV8 form the second control valve group. Group gating relay KA3 is used to perform gating control of the first control valve group and the second control valve group.

[0041] The eight control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com