Wiring device for pneumatic material-pressing mechanism of moveable medical waste treating machine

A wiring device and pneumatic technology are applied in the field of wiring devices of the pneumatic pressing mechanism of a movable medical waste treatment machine, which can solve the problems of cluttered pipelines, appearance quality affecting sales, affecting appearance, etc., and achieving the effect of easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

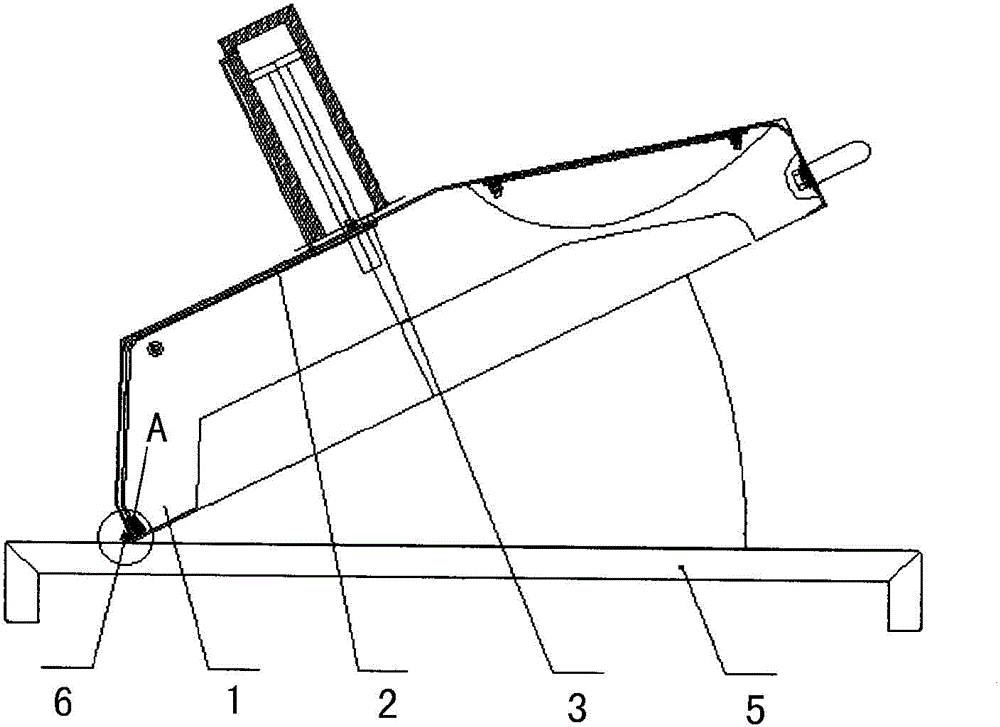

[0017] The present invention redesigns the wiring on the existing pneumatic pressing mechanism of the movable medical waste treatment machine. Specifically, the gas distributor 4 is fixed on the inner panel of the hopper cover 1 of the pneumatic pressing mechanism ( figure 1 A represents the fixed position of the gas distributor 4), the hopper cover 1 performs opening and closing rotary motion around the rotary shaft 6 in the fixed panel 5.

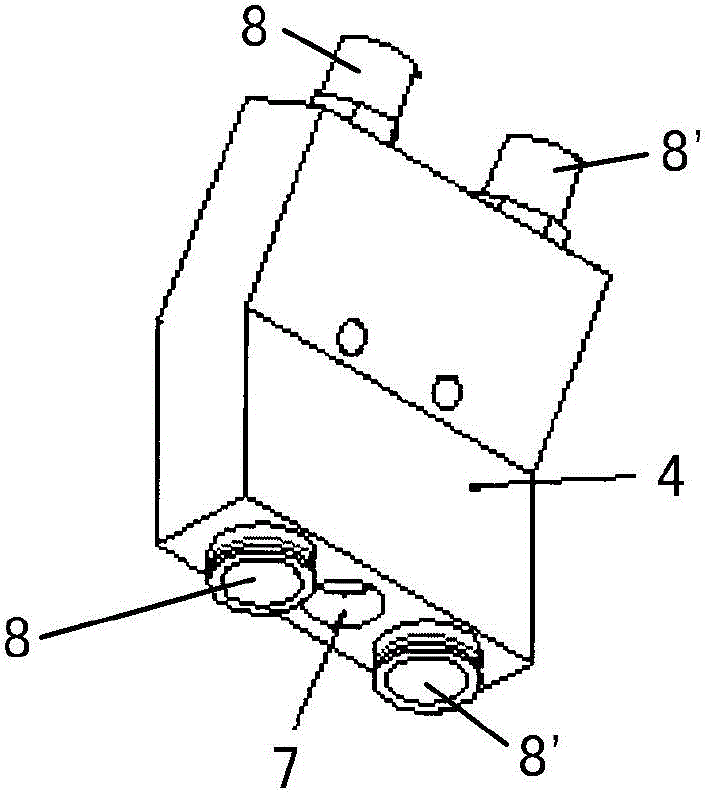

[0018] The gas distributor 4 has three through holes, wherein the through holes 8 and 8' on both sides are respectively used as the gas inlet hole and the gas outlet hole, the upper limit signal line and the lower limit signal line of the cylinder stroke inside the pneumatic pressure material mechanism and the cylinder stroke. The pressure indicator signal line is connected to the outlet terminal of the muffler through the through hole 7 in the middle of the gas distributor 4 . The two through holes 8, 8' at one end of the gas distributo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com