Method for unscrewing decollated bolts

A technology for bolts and fractures, applied in the field of bolt removal from broken ends, can solve the problems of rust, cumbersome operation, and difficulty in removing the bolt body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

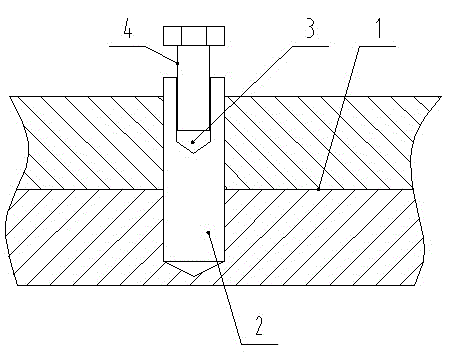

[0011] Such as figure 1 As shown, a method for taking out a dead end bolt of the present invention comprises the following steps in sequence:

[0012] (1) Flatten the broken part of the broken bolt 2 on the connector 1;

[0013] (2) Drill a hole 3 along the center line of the dead bolt 2 at the leveling place of the dead bolt 2, the hole diameter is smaller than the outer diameter of the dead bolt 2, and the drilling depth is 10-20mm;

[0014] (3) Select a suitable manual tapping tool according to the diameter of the drilled hole, and use a manual tapper to tap the drilled hole. The thread rotation in hole 3 is opposite to that of the dead bolt 2;

[0015] (4) Use a wrench to screw a small bolt 4 into the threaded hole 3 after tapping. Since the thread rotation direction in the hole 3 is opposite to that of the broken bolt 2, during the screwing process of the small bolt 4 , just drive the dead end bolt 2 to unscrew slowly, so that the dead end bolt 2 is disassembled from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com