Demolding device for concrete pipe pile

A technology of concrete pipe piles and demoulding devices, which is applied to ceramic molding machines and manufacturing tools, can solve problems such as long demoulding time, easy shaking of steel wire ropes, and scraping of concrete pipe piles, so as to achieve low labor intensity for workers and improve work efficiency. Reliability, the effect of ensuring the quality of pipe piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

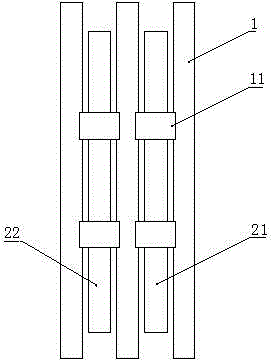

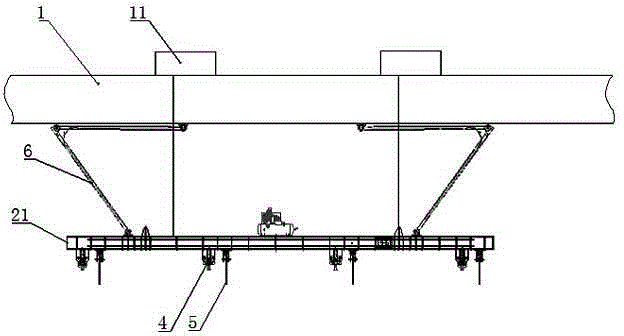

[0020] like figure 1 As shown, the demoulding device for concrete pipe piles includes two first movable spreaders 21 and a second movable spreader 22 arranged in parallel. Lifting trolley group 11 is set respectively between the row hanging crossbeams of the row, and the first movable spreader 21 and the second movable spreader 22 are located at the bottom of two lifting trolley groups, are respectively driven by these two independent lifting trolley groups to realize lifting.

[0021] An anti-sway mechanism is arranged between the first movable spreader 21, the second movable spreader 22 and the beam 1, see figure 2 , 5 , the anti-shake mechanism includes a folding arm 6, the upper and lower ends of the folding arm 6 are respectively hinged with the beam and the movable spreader. The folding plane of the folding arm 6 is perpendicular to the translational direction of the hanging guide rail.

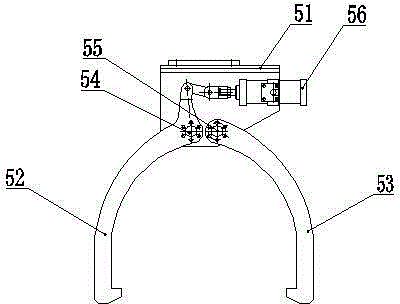

[0022] Cover mold mechanical claw 4 and bottom mold mechanical claw 5 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com