Independent front suspension structure of all-terrain four-wheel motorcycle

A motorcycle and all-terrain technology, applied in the axle suspension, bicycle accessories, transportation and packaging, etc., can solve the problems of short telescopic stroke, small size, short length of single-layer cantilever, etc., to achieve enhanced lateral stiffness and prevent excessive rotation , The effect of preventing wheel camber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

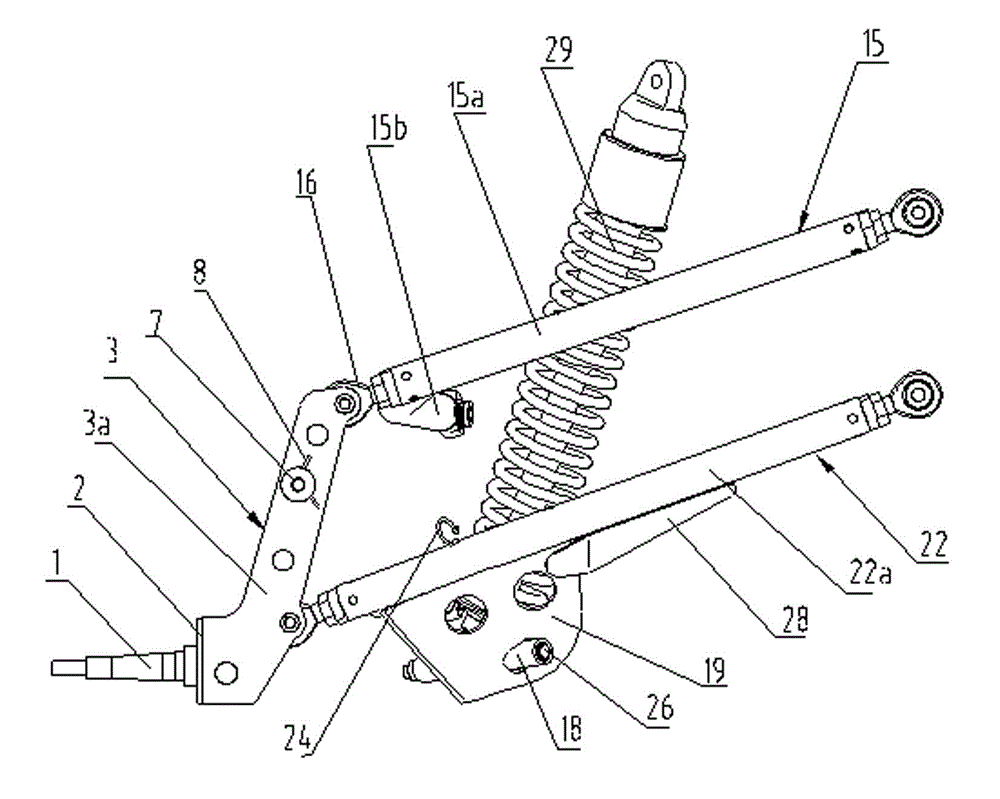

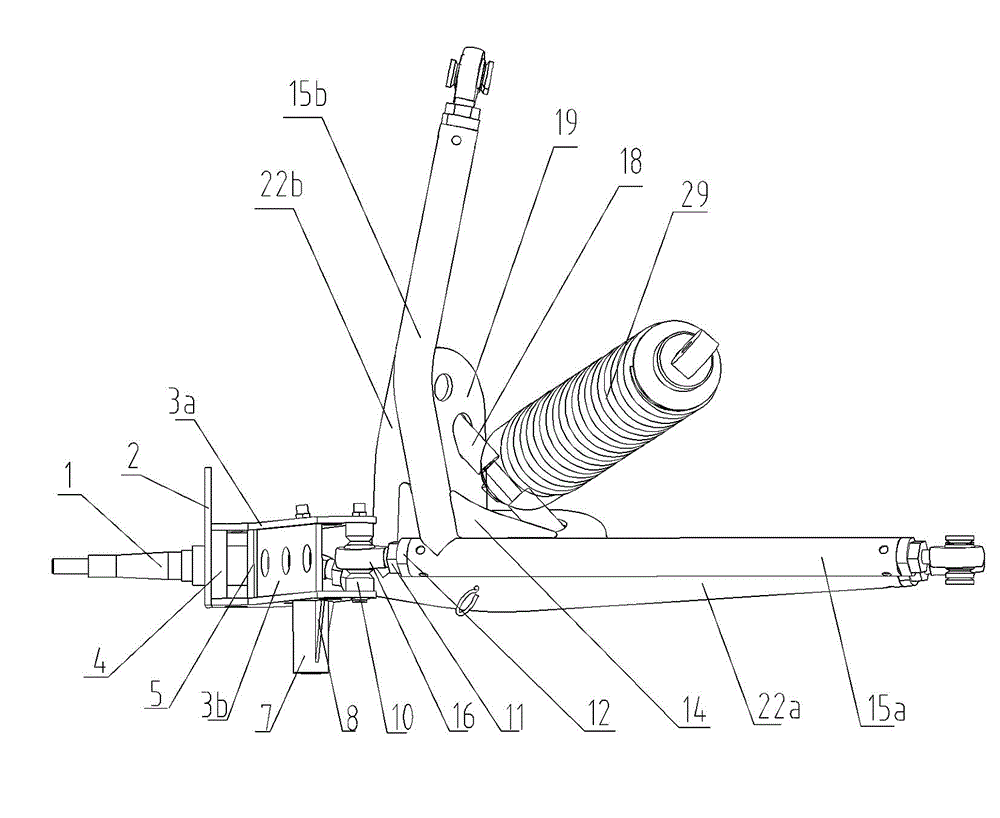

[0025] see figure 1 , figure 2 , a kind of embodiment of the independent front suspension structure of all-terrain four-wheel motorcycle, comprises shock absorber 29, steering knuckle assembly, upper suspension 15, lower suspension 22. The upper suspension 15 and the lower suspension 22 are all "herringbone" structures welded by the suspension front bar and the suspension side bar. The upper suspension front bar 15a is shorter than the lower suspension front bar 22a, and the upper suspension Joint bearings 16 are respectively provided at the two ends of the front bar 15a and the extension end of the upper suspension side bar 15b, and joint bearings 16 are respectively provided at the two ends of the lower suspension front bar 22a and the extension end of the lower suspension side bar 22b. The axial line of the bearing 16 extends horizontally. In order to ensure that the joint bearing is easy to assemble and can be installed firmly, this embodiment uses internal thread plugs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com