Polycrystalline silicon self-plugging casting device

A polysilicon, casting channel technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of difficult to achieve high-vacuum phosphorus removal, easy to burn through the furnace shell, explosion, etc., to reduce the continuous solidification and melting process, The effect of saving energy consumption and eliminating expansion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

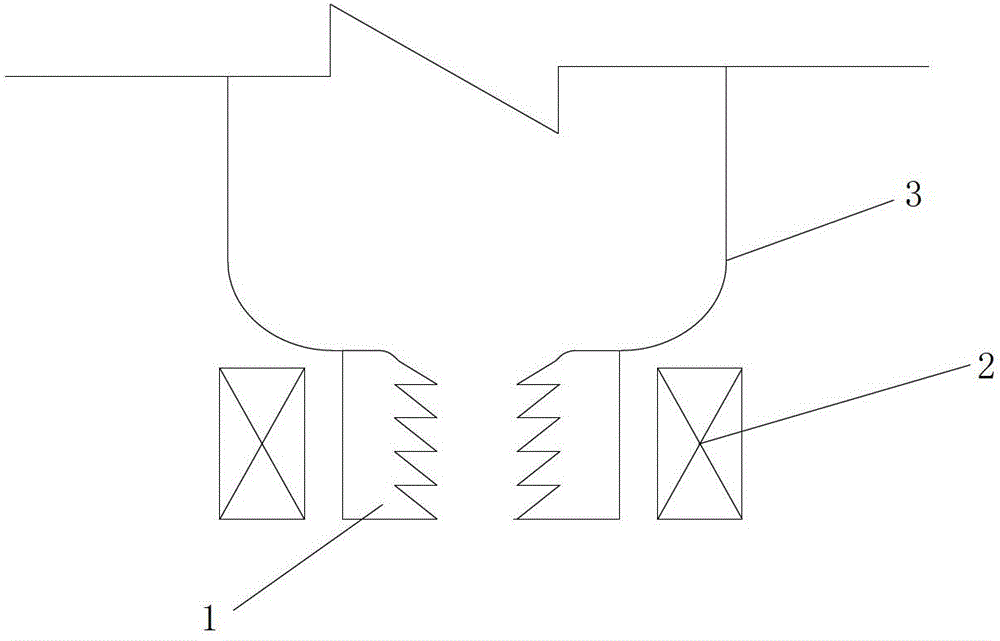

[0016] see figure 1 The embodiment of the present invention is provided with a casting channel 1, a heating system 2 and a melting crucible 3, the heating system 2 is arranged around the outside of the casting channel 1, and the bottom of the melting crucible 3 is connected to the casting channel 1 by threads.

[0017] The casting channel 1 may adopt a zigzag structure. The heating system 2 can adopt a self-induction heating system.

[0018] The smelting crucible 3 that the present invention adopts can directly carry out simple transformation to the crucible used in the existing 20kg (Si) overturning intermediate frequency furnace, adopts the smelting crucible 3 (material is graphite, screw hole inner diameter is 10cm) with internal thread hole at the bottom ), then the inner side of the casting channel 1 is designed as a zigzag structure with an inner diameter of 5 cm, and the top of the outer side is designed as a thread corresponding to the thread of the melting crucible, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com