Production reagents and production method for shorn sheep skin

A production method and sheep shearing technology, applied in dyeing method, leather surface treatment, small raw hide/large raw hide/leather/fur treatment, etc., can solve the problem of single color effect of quilt, and achieve good gloss and rich color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

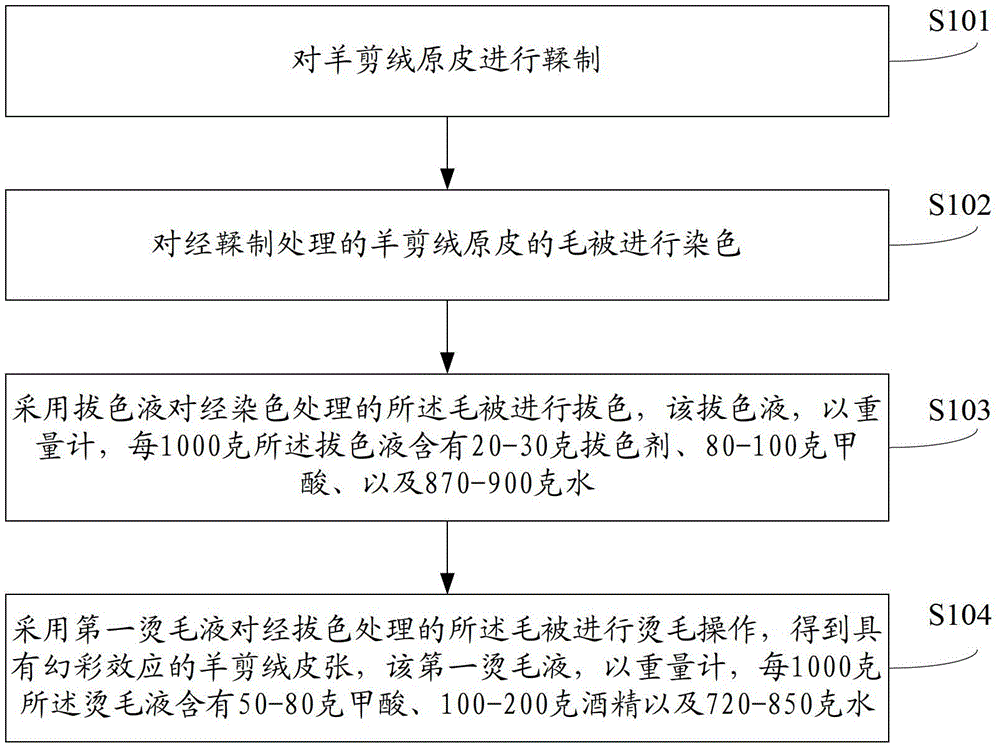

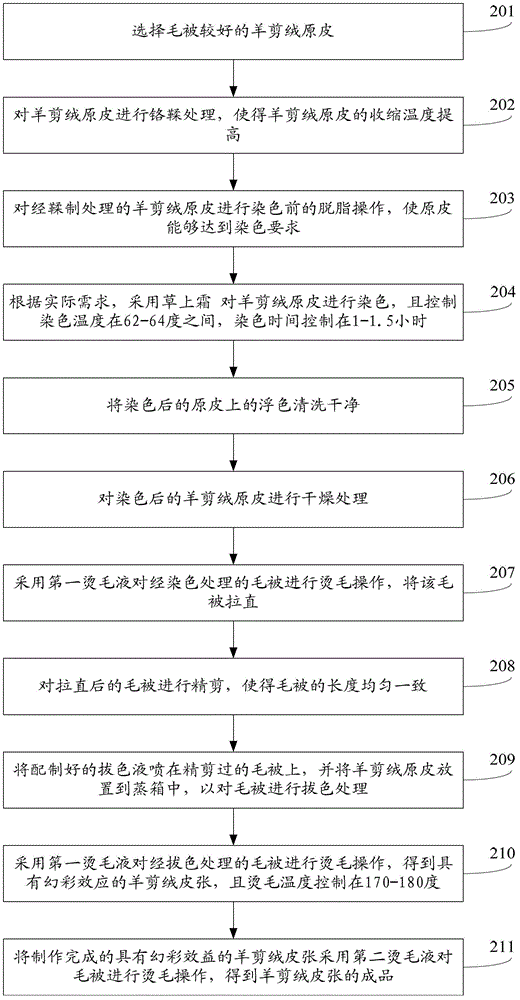

[0039] Embodiment 1 of the present invention provides a kind of medicament for making sheep shearling skin, comprising:

[0040] Draining liquid, which is composed of a color-draining agent, formic acid and water, and by weight, every 1000 grams of the color-draining liquid contains 20-30 grams of the color-draining agent, 80-100 grams of the formic acid, and 870- 900 grams of water;

[0041] The hair scalding liquid is composed of formic acid, alcohol and water, and by weight, every 1000 grams of the hair scalding liquid contains 50-80 grams of the formic acid, 100-200 grams of the alcohol and 720-850 grams of water.

[0042] The preparation medicament for the sheep shearling hide provided in the first embodiment of the present invention, the proportioning of each content in the color pulling liquid and the scalding liquid, make after the hair quilt of the raw sheep shearling hide is subjected to the color pulling treatment and the scalding treatment, the production The flee...

Embodiment 2

[0044] Embodiment 2 of the present invention provides another medicament for making sheep shearling skins, including:

[0045] Draining liquid, which is composed of a color-draining agent, formic acid and water, and by weight, every 1000 grams of the color-draining liquid contains 20-30 grams of the color-draining agent, 80-100 grams of the formic acid, and 870- 900 grams of water;

[0046] Hair scalding liquid, which is composed of brightener, formic acid, alcohol and water, and by weight, every 1000 grams of the hair scalding liquid contains 20-30 grams of the brightening agent, 50-80 grams of the formic acid, 100-200 gram of alcohol, and 690-830 gram of water.

[0047] Because the scalding liquid contains a brightener in a certain proportion, the glossiness of the wool quilt is better after scalding the wool quilt of the raw sheep shearling hide.

Embodiment 3

[0049] Embodiment 3 of the present invention provides another kind of medicament for making sheep shearling skin, comprising:

[0050] Described color-extracting liquid is made up of color-extracting agent, formic acid and water, and by weight, every 1000 grams of described color-extracting liquid contains 25 grams of said color-extracting agent, 90 grams of said formic acid, and 885 grams of water;

[0051] The hair scalding liquid is composed of brightener, formic acid, alcohol and water, and by weight, every 1000 grams of the hair scalding liquid contains 25 grams of the brightening agent, 70 grams of the formic acid, 150 grams of the alcohol, and 755 grams of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com