Prestressed concrete pipe pile with reinforcing rings

A technology of concrete pipe piles and concrete pipes, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems that affect the performance, easy damage, fracture, etc., and achieve the effect of improving the overall bearing capacity and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

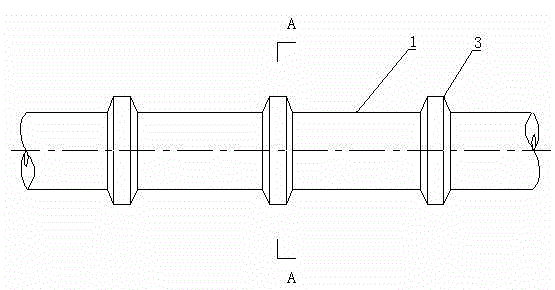

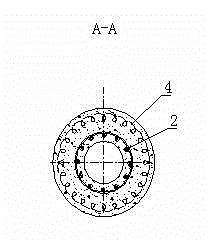

[0010] Such as figure 1 , 2 As shown, it includes a concrete pipe body 1, a reinforcement cage 2, a concrete reinforcement ring 3, and reinforcement ribs 4.

[0011] The above-mentioned concrete pipe body 1 is provided with a reinforcement cage 2, and on the surface of the concrete pipe body 1, there are concrete reinforcement rings 3 formed integrally with the concrete pipe body 1 at intervals along the axial direction, and reinforcement ribs 4 are provided in the concrete reinforcement ring 3. The reinforcing rib 4 has a ring shape as a whole, and the reinforcing rib 4 itself has a spiral structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com