Punching mechanism of automatic twisting machine of spindle-type drilling machine

A kind of pipe twisting machine, vertical shaft technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problem of large area of hydraulic pipe twisting machine, achieve small footprint, large impact force, simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

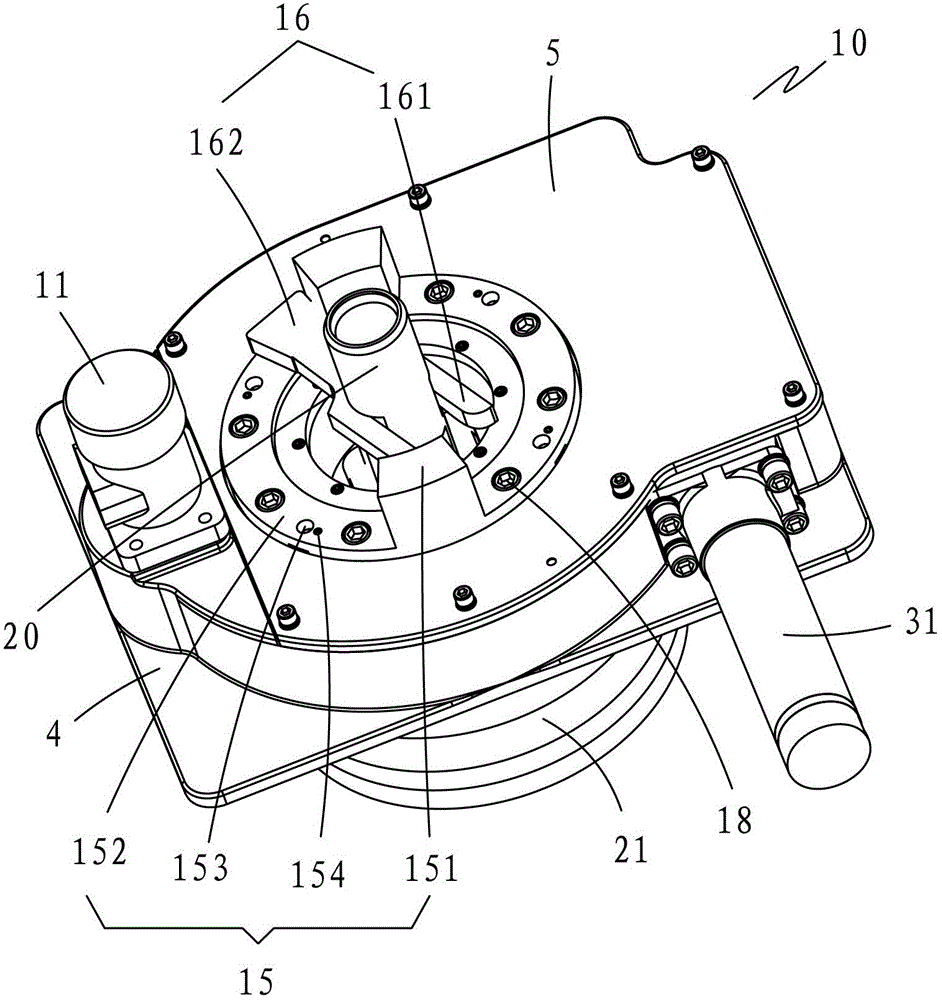

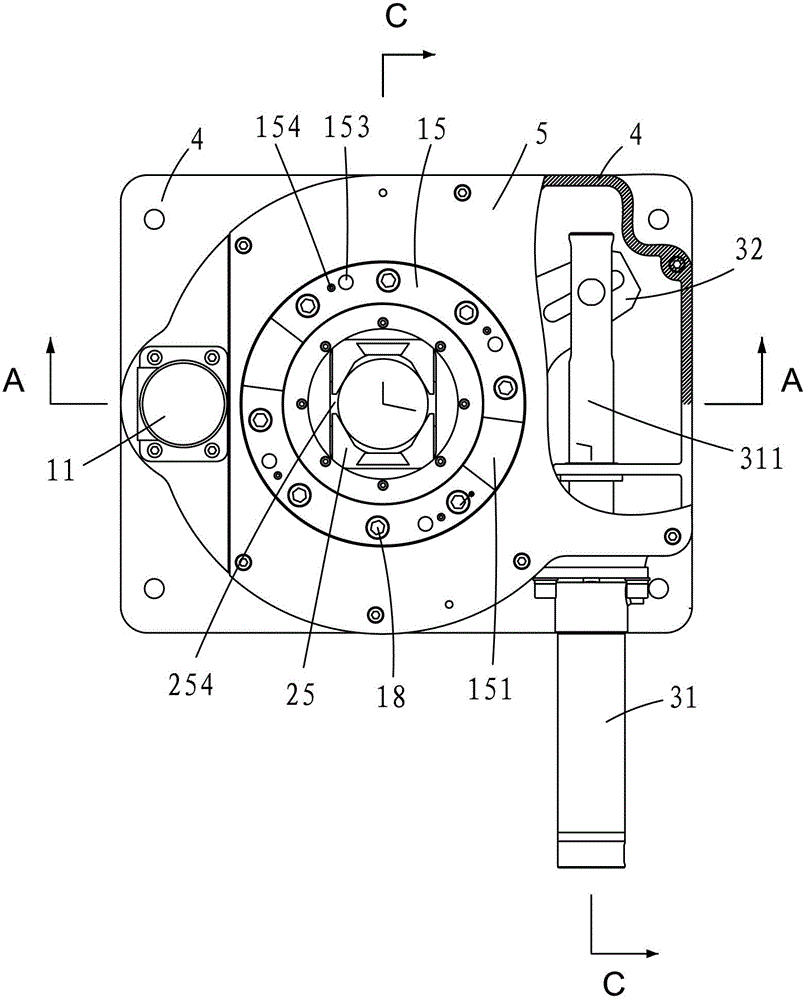

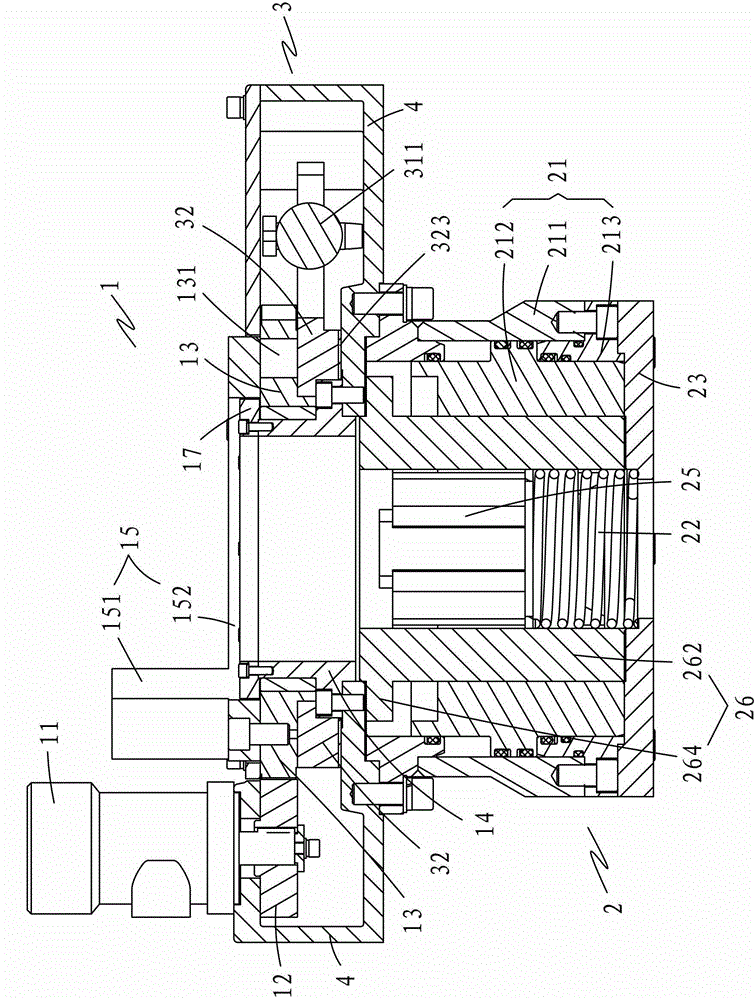

[0028] Such as Figure 1 to Figure 4 As shown, the automatic pipe twister 10 of the vertical shaft drilling rig utilizing the punching mechanism of the present invention includes a screwing mechanism 1, a clamping mechanism 2, a punching mechanism 3 of the present invention, a base 4 and an upper cover 5. Wherein, the clamping mechanism 1 is used to clamp the bottom of the drill rod, and the unscrewing mechanism 2 is used to rotate the upper drill rod 20 to unload the upper drill rod 40 from the lower drill rod 20 or to screw the upper drill rod 20 into the lower drill rod 40. The punching mechanism 3 is used to give the unscrewing mechanism 1 an instantaneous impact force, so that the unscrewing mechanism 1 has enough power to unscrew the upper drill pipe 20 from the lower drill pipe 40 . The buckle mechanism 3 can also be used for locking after the upper drill pipe 20 is screwed into the lower drill pipe 40 by adjusting the direction of the pawl, so as to ensure the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com