Optical interference type intelligent gas sensor

A technology of gas sensor and optical interference, which is applied to the measurement of phase influence characteristics, etc., can solve the problems of short calibration cycle, complex calibration, and complex operation, and achieve the advantages of overcoming large visual errors, stable measurement performance, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

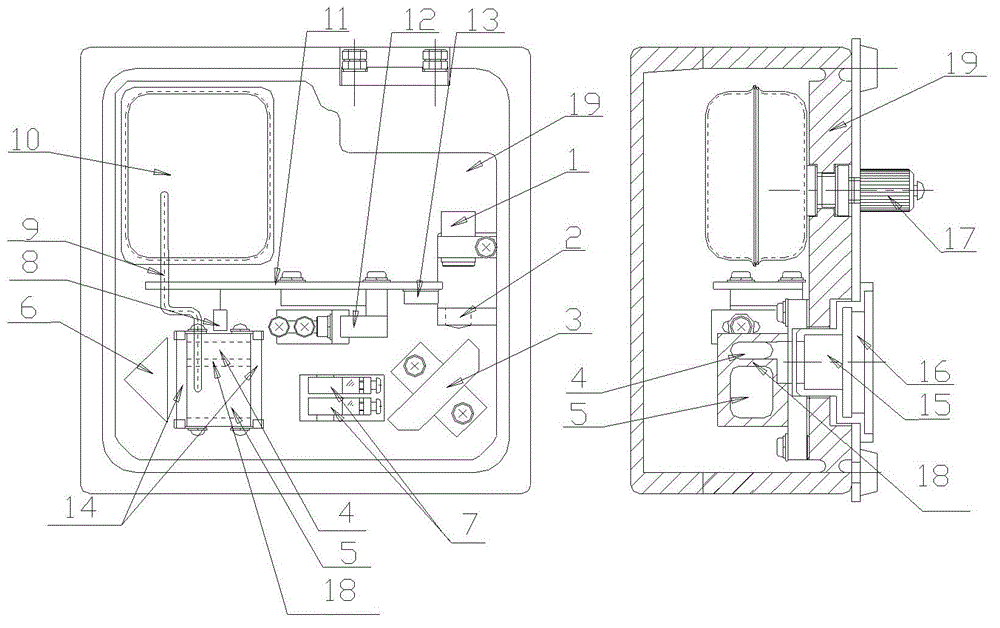

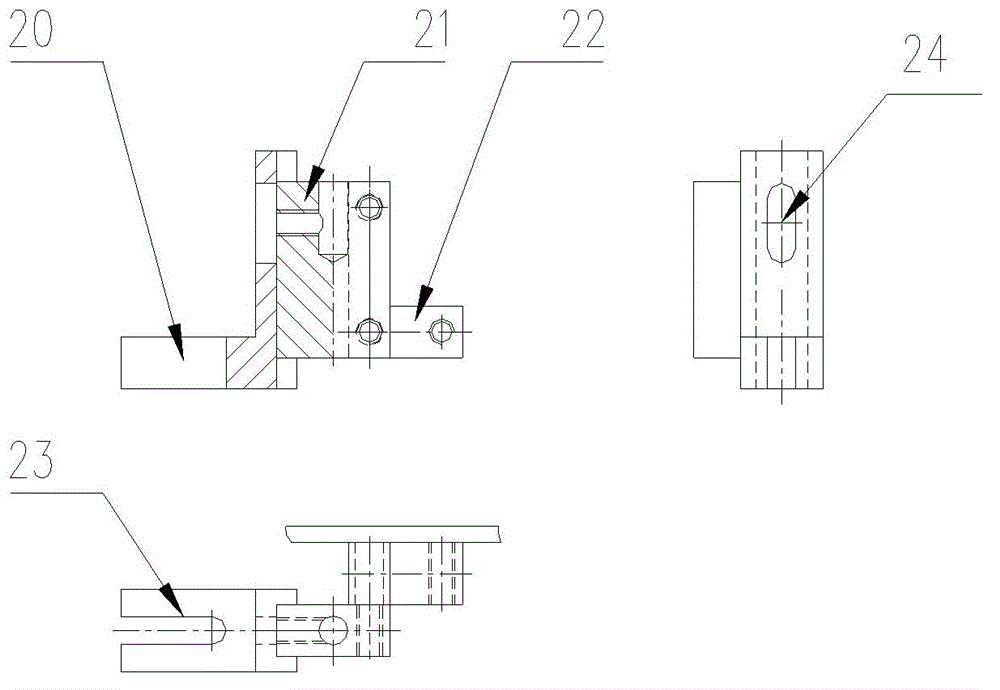

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

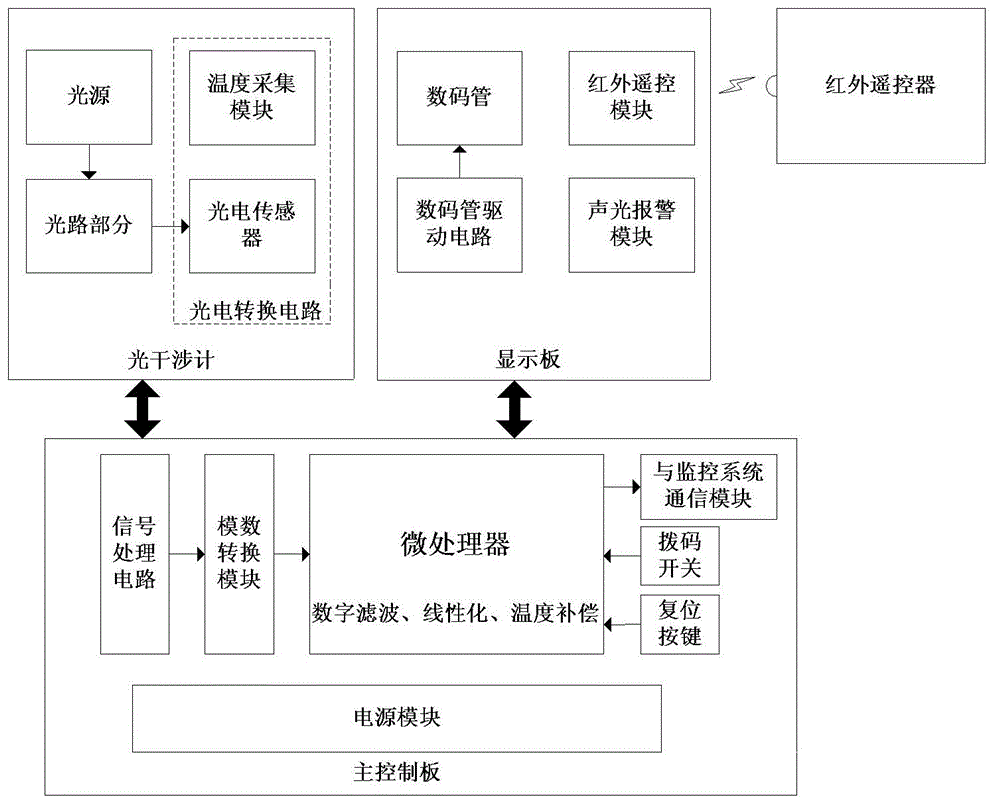

[0021] figure 1 It is a structural block diagram of the optical interference type intelligent gas sensor of the present invention. refer to figure 1 , the sensor system includes an optical interferometer, a main control board, a display board, and an infrared remote controller.

[0022] The optical interferometer includes a light source, an optical path, a photoelectric sensor and a temperature acquisition module.

[0023]The main control board includes a signal processing circuit, an analog-to-digital conversion module, a microprocessor, a communication module with a monitoring system, a power supply module, a dial switch, and a reset button. The signal processing circuit includes an active low-pass filter and a diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com