Device and method for detecting turn-to-turn insulation failure of rotor winding of generator

A generator rotor and rotor winding technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of many influencing factors, insufficient sensitivity of inter-turn short circuit fault detection, detection accuracy, and low sensitivity, and achieve The detection is direct and accurate, and the effect of solving the short circuit fault detection between rotor turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate a further understanding of the structure, method and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

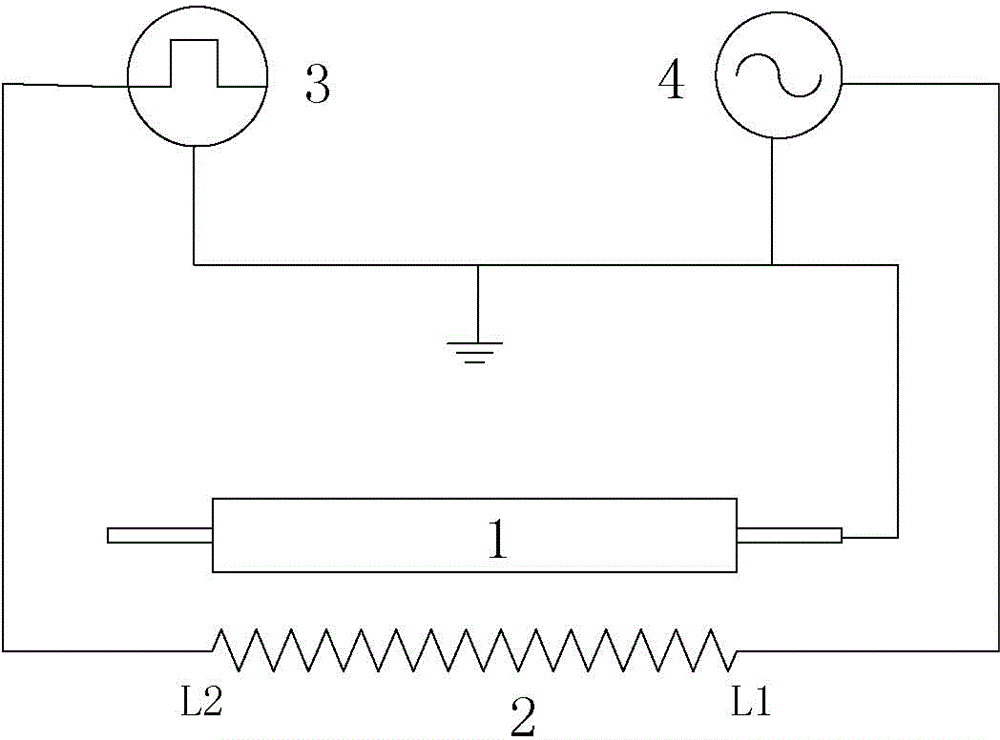

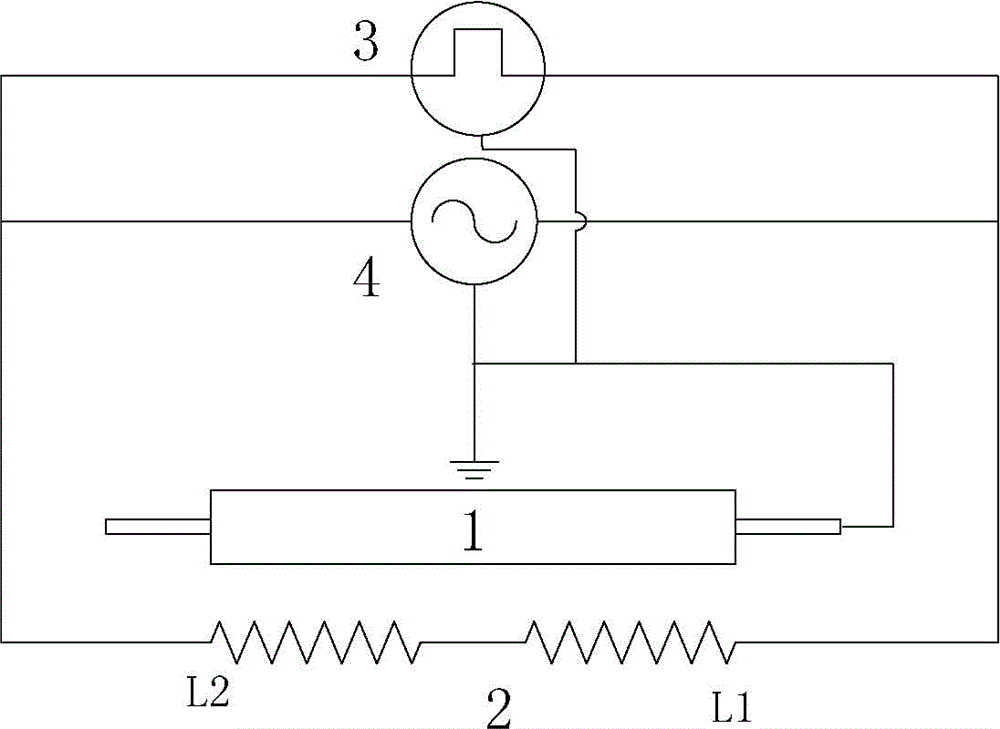

[0030] The detection device of the inter-turn insulation fault of the motor rotor winding of the present invention includes a signal generator 3 and a digital oscilloscope 4, the signal generator 3 and the digital oscilloscope 4 are connected to the two ends of the rotor winding 2, and the signal generator 3 is connected to the rotor winding 2 An excitation signal is applied at one end, and a response signal is output at the other end of the rotor winding 2, and the response signal is received and displayed by the digital oscilloscope 4. At the same time, the digital oscilloscope 4 records and stores the excitation and response signals. The difference between the response signals output from both ends of the winding 2 determines whether there is an insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com