Special pure electric vehicle coaxial combination brushless DC motor with functions of power self-regulating and temperature control

A DC motor, pure electric vehicle technology, applied in electric vehicles, electric components, motors, etc., can solve the problem of high cost of variable frequency controllers, and achieve the effects of improving efficiency and service life, low manufacturing cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

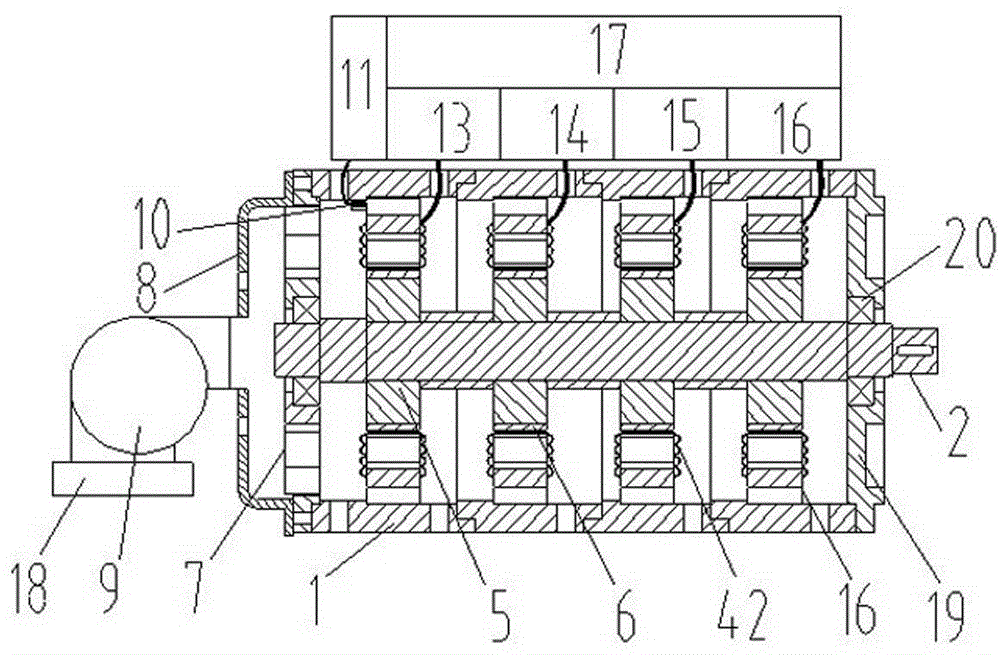

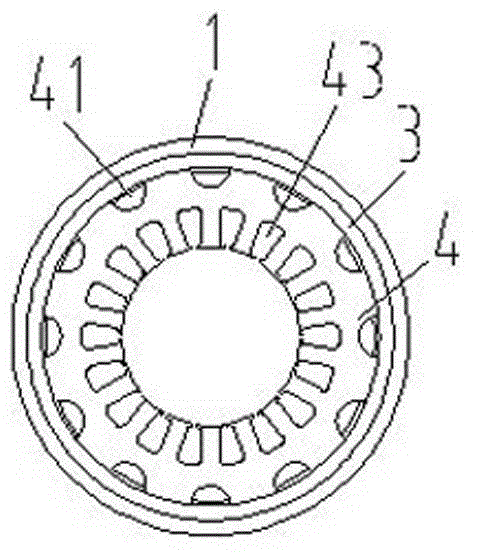

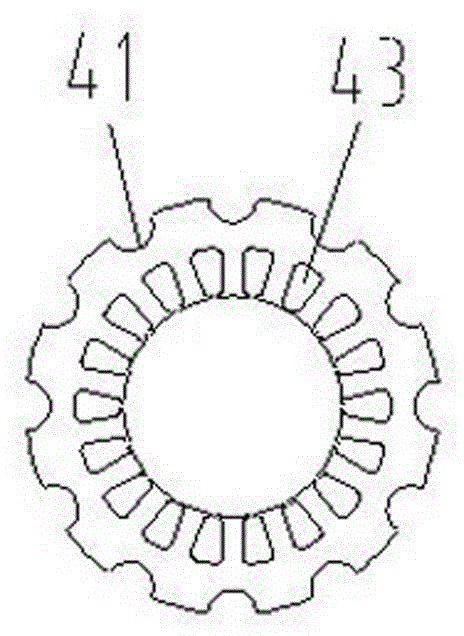

[0031] see figure 1 , in this embodiment, four stators of the same structure are evenly installed coaxially with the rotating shaft 2 in the machine base 1, and four rotors of the same structure are correspondingly installed on the rotating shaft 2, and each stator and each corresponding rotor form four columns Type motor. see figure 2, is a schematic diagram of the end surface structure of the stator (with frame) in the column motor of this embodiment, which includes a cylindrical stator bracket 3 installed in the frame 1, and a stator core 4 fixed in the stator bracket 3, the stator Support 3 can be made of materials such as aluminum alloy, fiberglass, steel plate. see image 3 , is a schematic diagram of the end face structure of the stator core 4. The stator core 4 is formed by laminating annular silicon steel sheets. image 3 It can be seen that the outer circumference of the stator core 4 is provided with several semicircular ventilation holes 41 , and the inner cir...

Embodiment 2

[0033] see Figure 8 , in this embodiment, four stators of the same structure are evenly installed coaxially with the rotating shaft 2 in the machine base 1, and four rotors of the same structure are correspondingly installed on the rotating shaft 2, and each stator and each corresponding rotor form four sets Disc motor. The structure and connection relationship of the base, the end cover, the bearing, the rotating shaft and the peripheral equipment of the base in this embodiment are the same as those in the first embodiment. The difference is that the stators and the corresponding rotors in this embodiment form four disc-type sub-motors, the stators include a disc-shaped stator support 21 installed in the machine base 1, and the stator support 21 can be aluminum alloy, glass steel, Made of steel plate and other materials. like Figure 8 , Figure 9 , Figure 10 As shown, one end surface of the stator bracket 21 is fixedly connected to one end surface of the stator core 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com