Manufacturing method for circuit board

A production method and circuit board technology, which are applied in the reinforcement of conductive patterns, secondary processing of printed circuits, etc., can solve problems such as short circuit of circuit board products, and achieve the effects of avoiding gold long corners, avoiding side erosion, and improving production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The manufacturing method of the circuit board provided by the first embodiment of the technical solution includes the following steps:

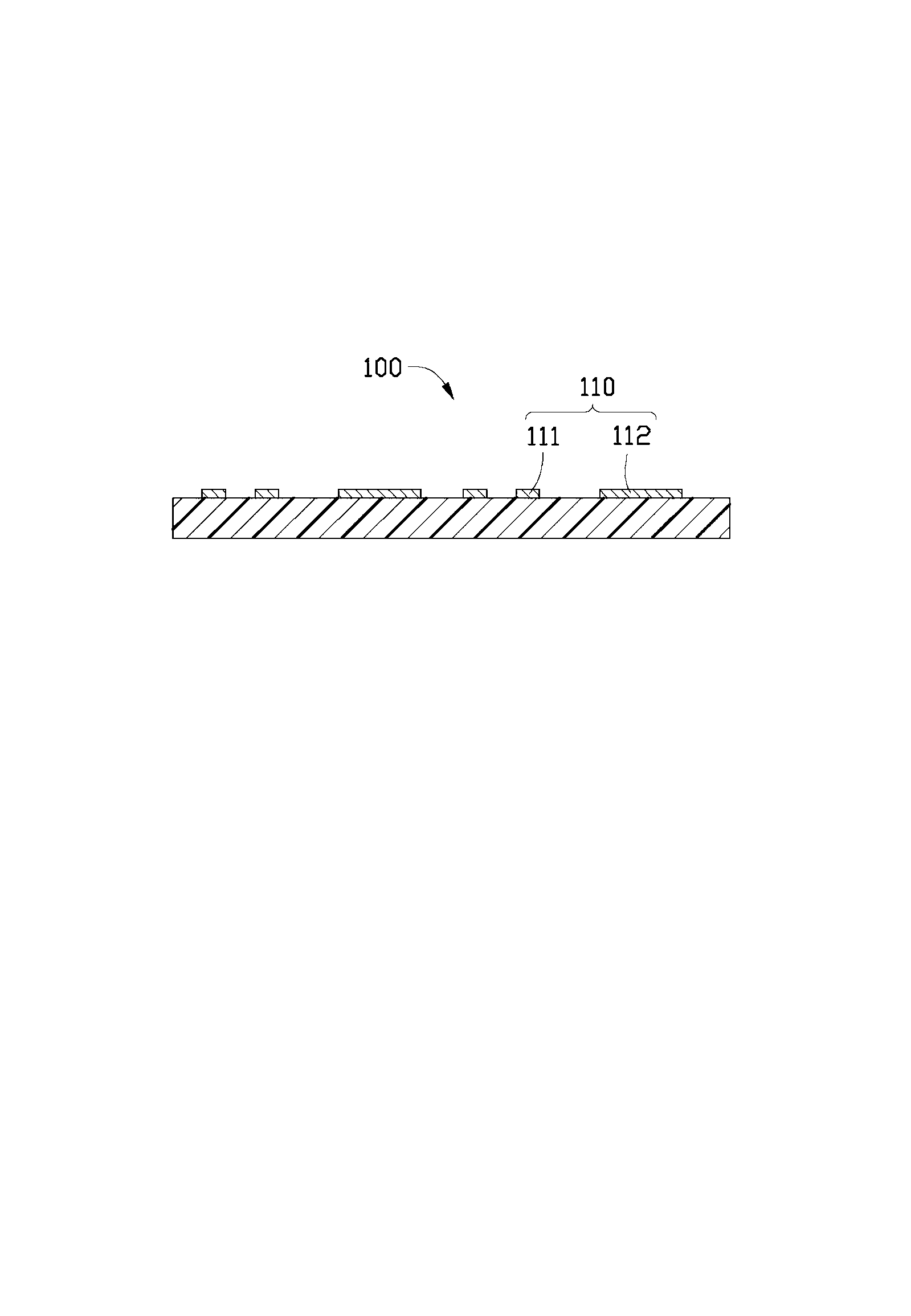

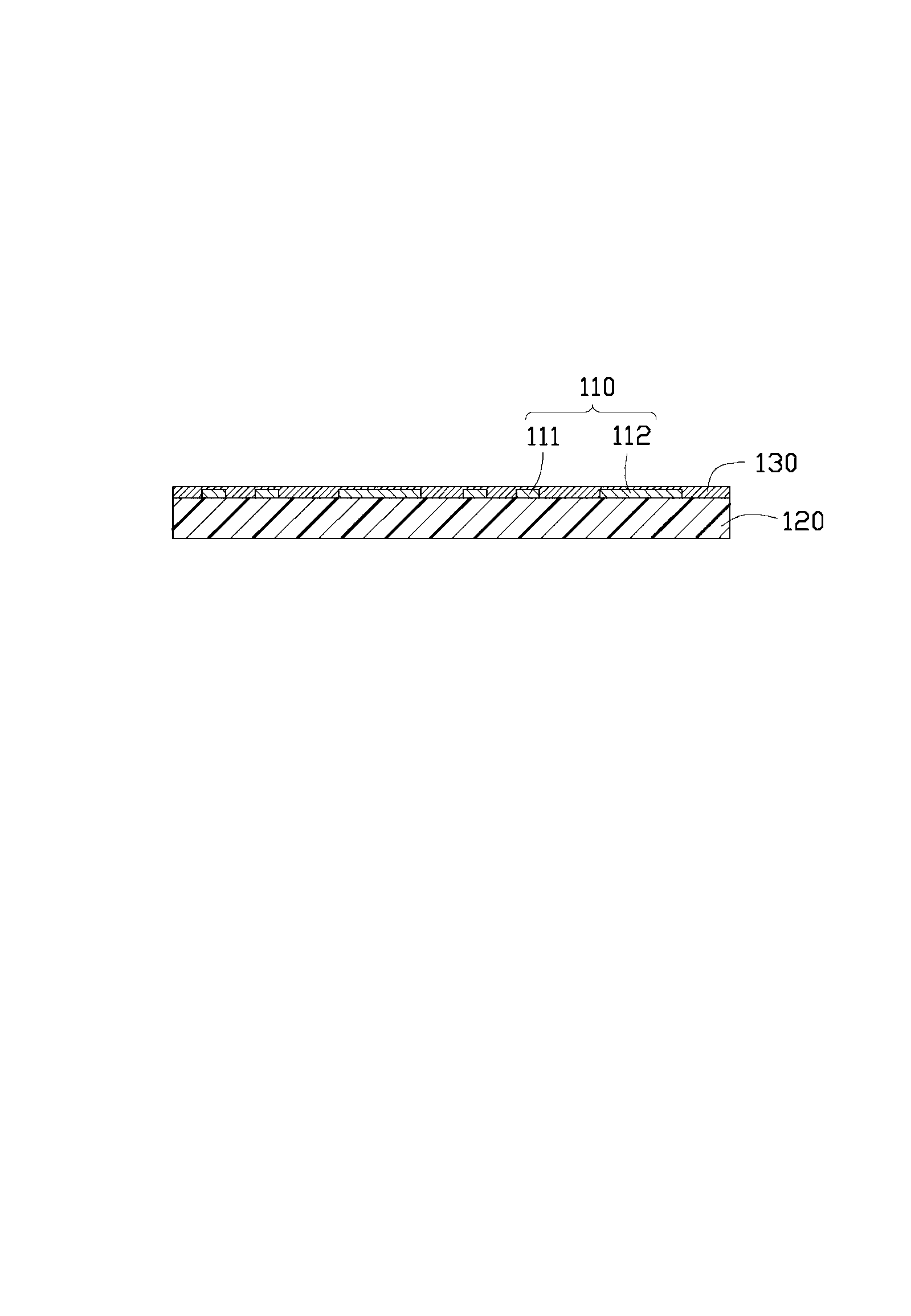

[0022] For a first step, see figure 1 , providing a substrate 100 .

[0023] The substrate 100 includes a substrate layer 120 and a circuit pattern 110 formed on the substrate layer 120 . The circuit pattern 110 includes a plurality of conductive circuits 111 and a plurality of pads 112 for electrically communicating with the outside world. Each pad 112 is in electrical communication with one or more conductive lines 111 . The substrate 100 may be a single-sided circuit board, or a double-sided circuit board or a multi-layer circuit board, that is, the substrate layer 120 may be an insulating layer, or may include alternately arranged conductive layers and insulating layers. In this embodiment, the substrate 100 is a single-sided circuit board, and the base material layer 120 is an insulating layer.

[0024] It can be understood th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com