Carbon absorption tower

A carbon absorbing tower and tower body technology, which is applied to the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., to achieve the effects of saving floor space, reducing pollution, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

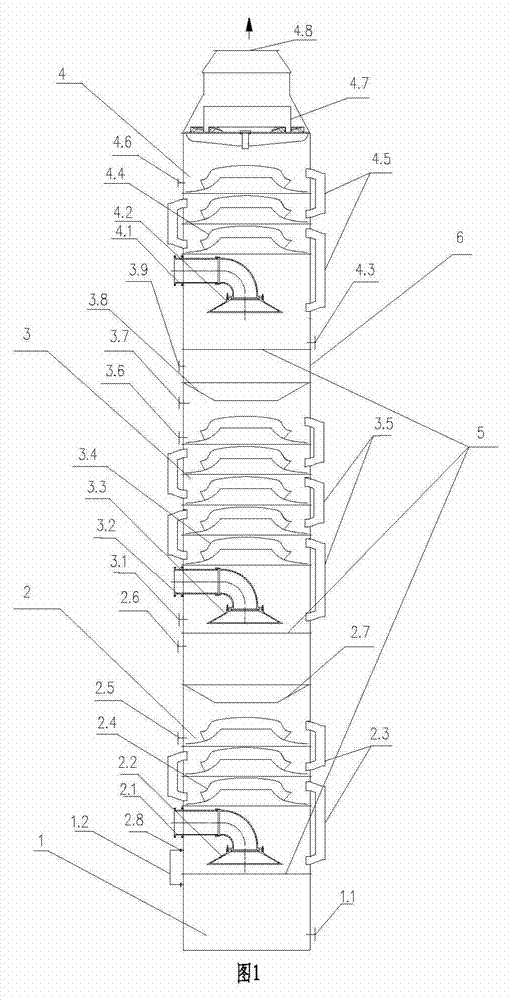

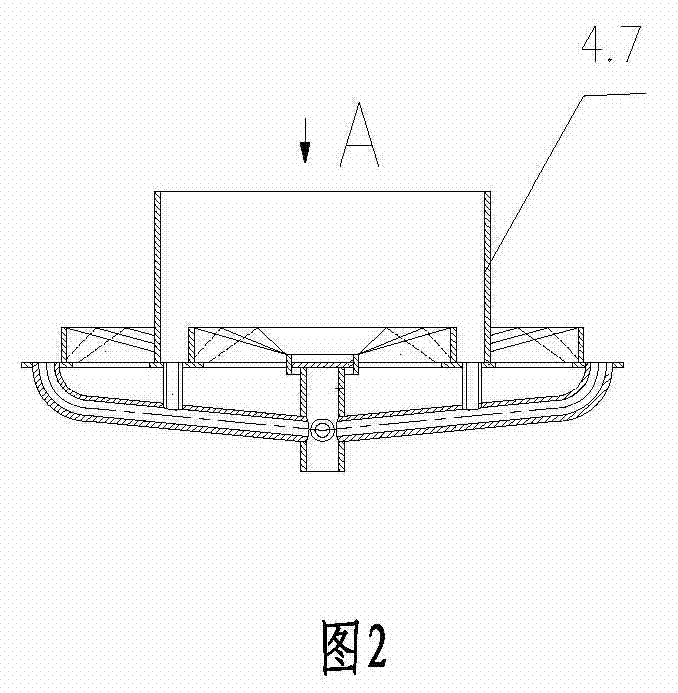

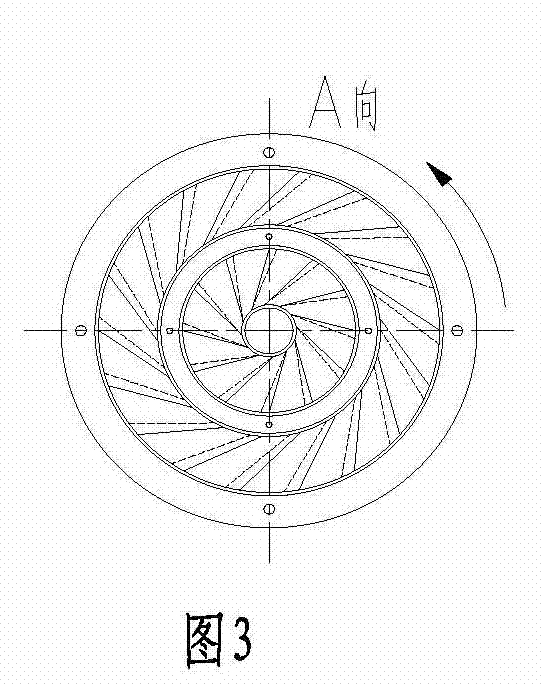

[0016] figure 1 It is shown that the tower body 6 is provided with four parts from top to bottom, namely, the purification section 4, the carbon absorption section 3, the ammonia absorption section 2, and the carbon absorption liquid storage tank 1. The four sections are separated by three partition plates 5 open. The tower is a hat tower. The three sections of hat 2.4, 3.4, and 4.4 have the same shape and structure, and the flue gas flowing in the hat is also the same. Figure 4 Shows the flow state of the flue gas in the ammonia suction section 2 in the hat 2.4. The three liquid overflow pipes 2.3, 3.5, and 4.5 have the same shape and structure. The liquid overflow pipes are all arranged on both sides of the tower body 6. In this embodiment, the liquid overflow pipe is an arc-shaped single overflow pipe. The outlet of the overflow pipe is opposite to the inlet of the liquid overflow pipe on the other side. This structure can effectively control the liquid level and the orderl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com