Identification and separation device and method for waste plastics

A technology for waste plastics and separation devices, which is applied in the direction of solid separation, electrostatic effect separation, chemical instruments and methods, etc. It can solve the problems of being easily disturbed by external conditions, high requirements for the working environment, and expensive prices, and achieves the elimination of high requirements for the working environment. , easy on-site operation, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples, but of course the following examples should not be construed as limiting the present invention.

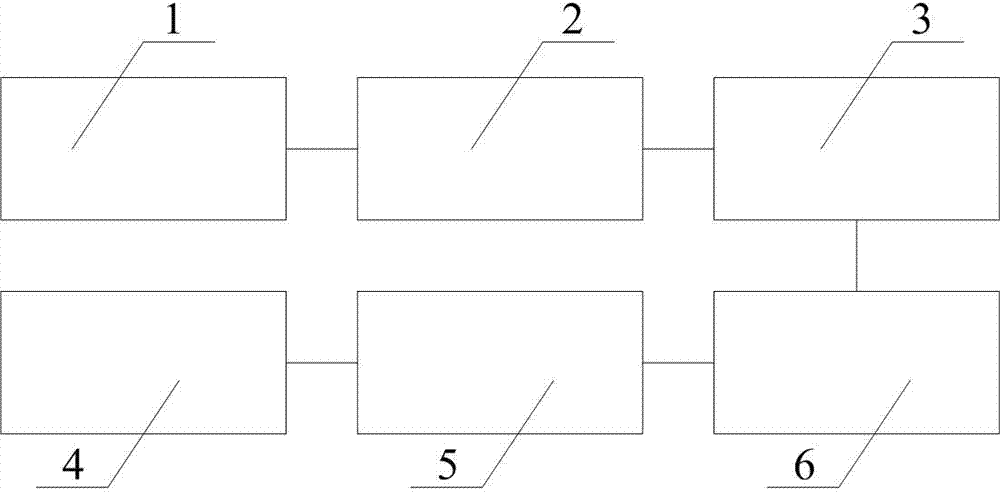

[0029] The present invention provides a device for identifying and separating waste plastics, which is characterized in that it includes a crushing device 1 , a friction device 2 , an acceleration device 3 , a constant magnetic field device 4 , a comparison device 5 , and a collection device 6 . The crushing device 1 is used for crushing various standard pure plastics and waste plastics into particles with the same particle size. The friction device 2 is used to charge the plastic particles crushed by the crushing device through friction. The acceleration device 3 is used to accelerate the frictionally charged plastic particles. The constant magnetic field device 4 is used to provide a constant magnetic field to the accelerated charged plastic particles, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com