Multi-target optimization and color-matching method of special-color ink in offset printing

A multi-objective optimization, ink technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as difficult practical application, and achieve the effect of reducing spectral heterogeneity, eliminating influence, and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

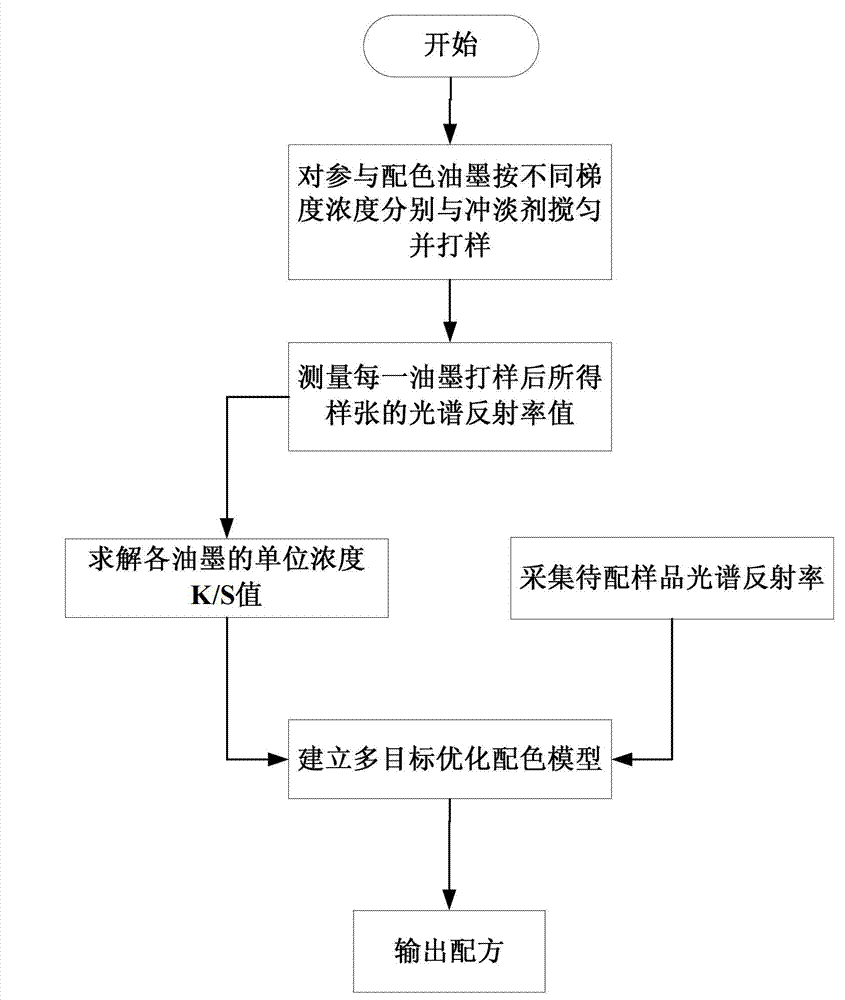

[0043]Embodiment: An actual offset printing ink spot color matching process is taken as an example to illustrate the operation process and details of the present invention.

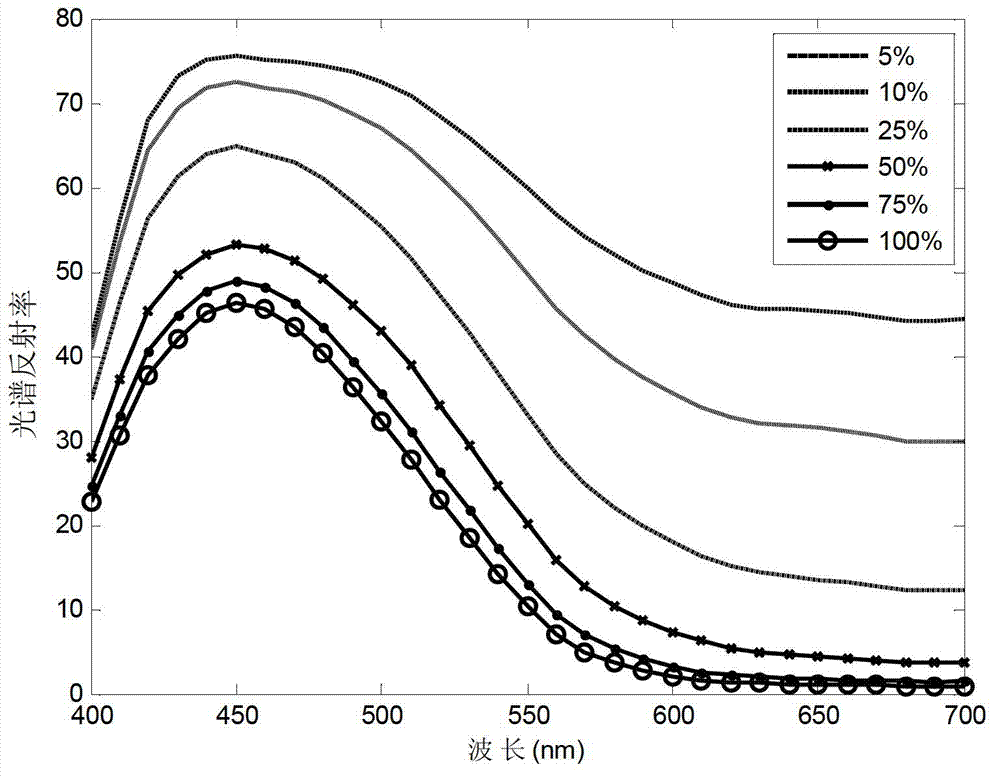

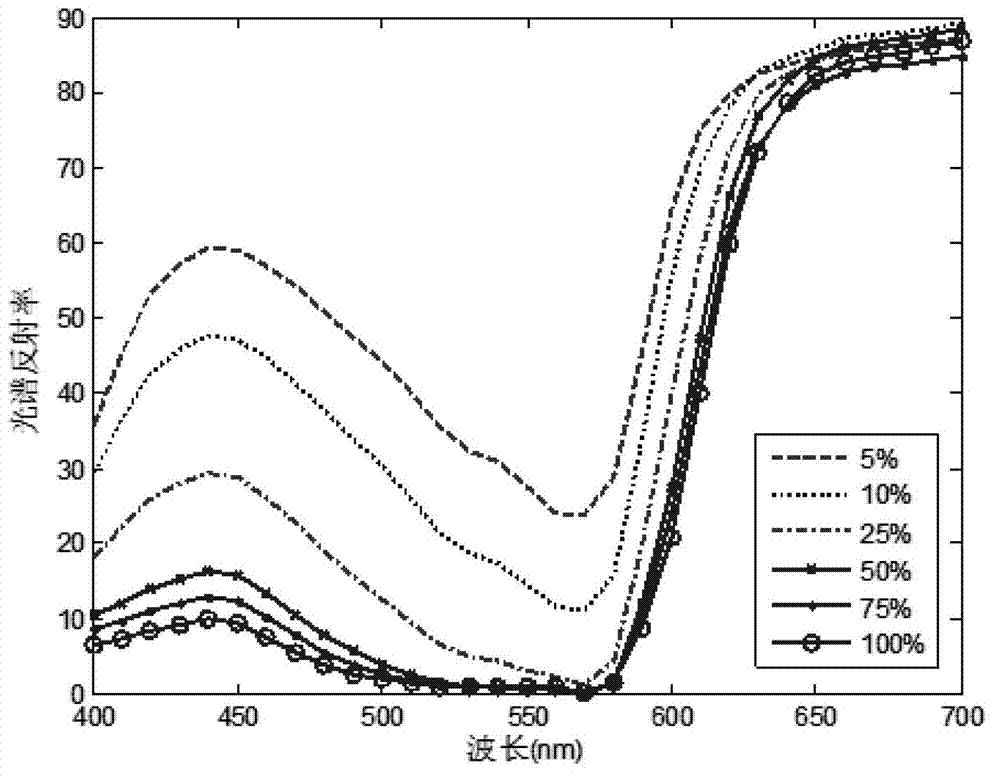

[0044] Step (1): Calibration and coloring. Here, three inks of medium yellow (Y), magenta (M) and medium blue (B) produced by Hanghua Ink Co., Ltd. are used as base colors, according to 5%, 10%, 25%, 50%, 75%, 100% gradient concentrations are mixed with diluent, mixed evenly, and proofed with IGT C1 offset printing ink proofer under 550N pressure, and measured with X-rite530 spectrophotometer, and D50 light source is selected for measurement and 2-degree viewing angle, each sample was measured 3 times to obtain the spectral reflectance curve of medium yellow (Y) under different gradient concentrations (such as figure 2 ), the spectral reflectance curves of magenta (M) at different gradient concentrations (such as image 3 ), the spectral reflectance curves of medium blue (B) under different gradient con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com