Comprehensive protector for crane

A comprehensive protector and crane technology, which is applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of high failure rate, large space occupation, and single function, so as to achieve high environmental adaptability and ensure long-term stability The effect of excellent operation and high system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

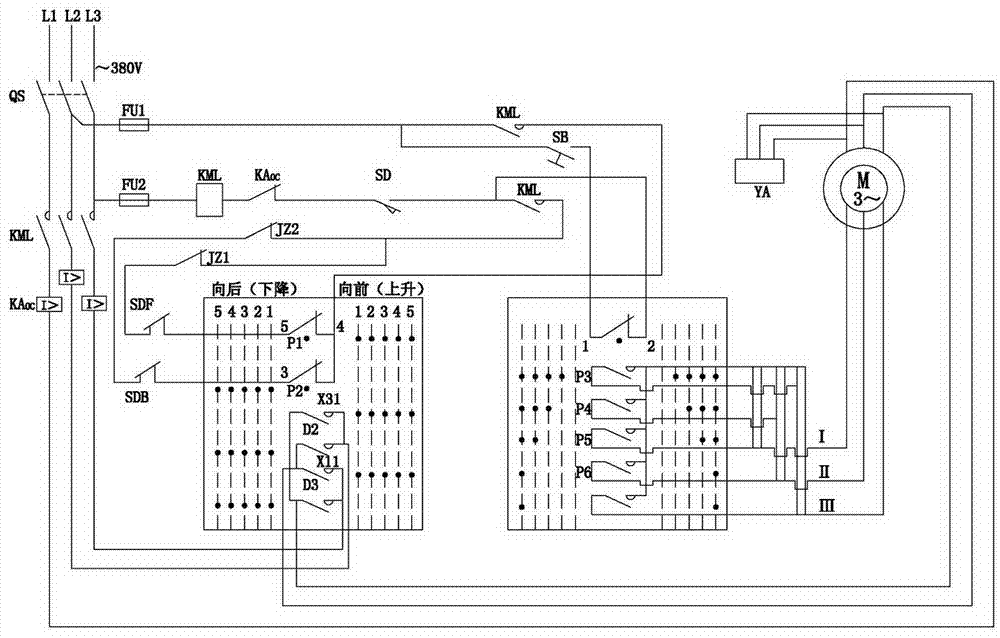

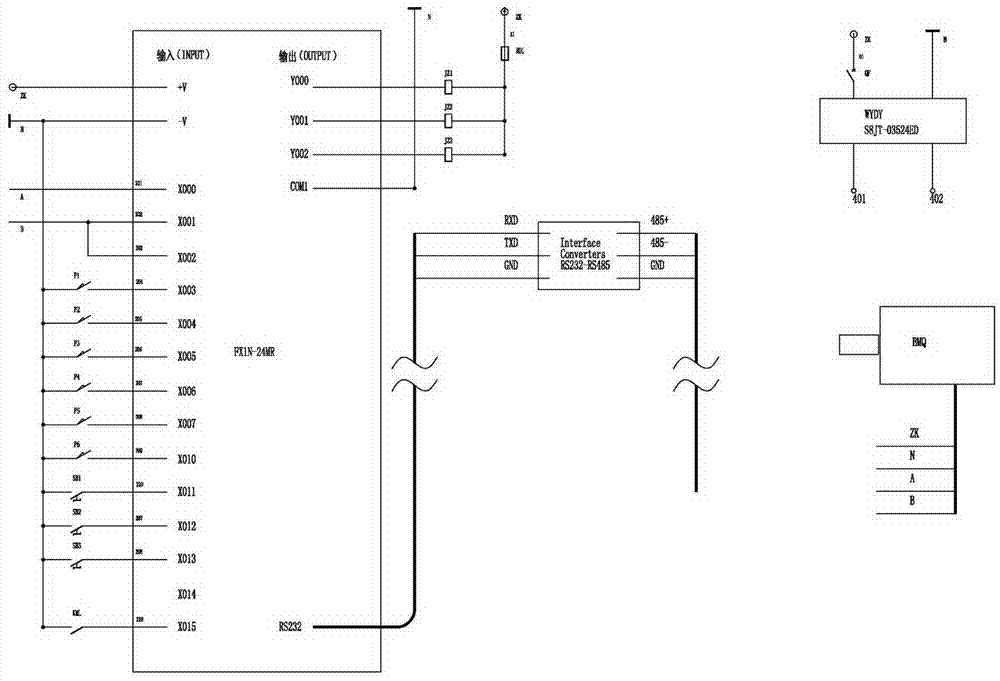

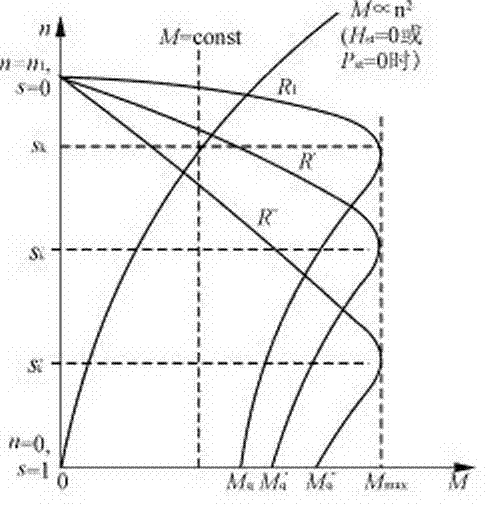

[0043] The invention is composed of a rotary encoder installed on the main shaft of the hoisting motor, a position sensor installed on the cam controller and a PLC controller. The PLC controller detects the motor speed signal and the position signal of the sensor, and outputs the control signal through data processing. signal, control the relays JZ1 and JZ2 to stop the motor. The output end of the PLC controller is also connected with a relay JZ3, the normally closed contact of the relay JZ3 is connected in the alarm bell circuit, and the action of the contact of the relay JZ3 sends out an alarm signal. The RS232 terminal of the PLC controller is connected to the RS485 terminal of the remote text display through an adapter, and the information on the PLC can be displayed through the remote text display. The position sensor that the present invention is installed on the crane cam controller is to adopt 6 microswitches to be respectively installed in the different gear positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com