Method for reusing recycled water in circulating cooling water

A technology of circulating cooling water and reclaimed water, applied in the direction of complex/solubilizer treatment, etc., can solve the problems of circulating cooling water system corrosion, pipeline corrosion, etc., to ensure safety, reduce the amount of dosing and treatment costs, and solve pipeline corrosion. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

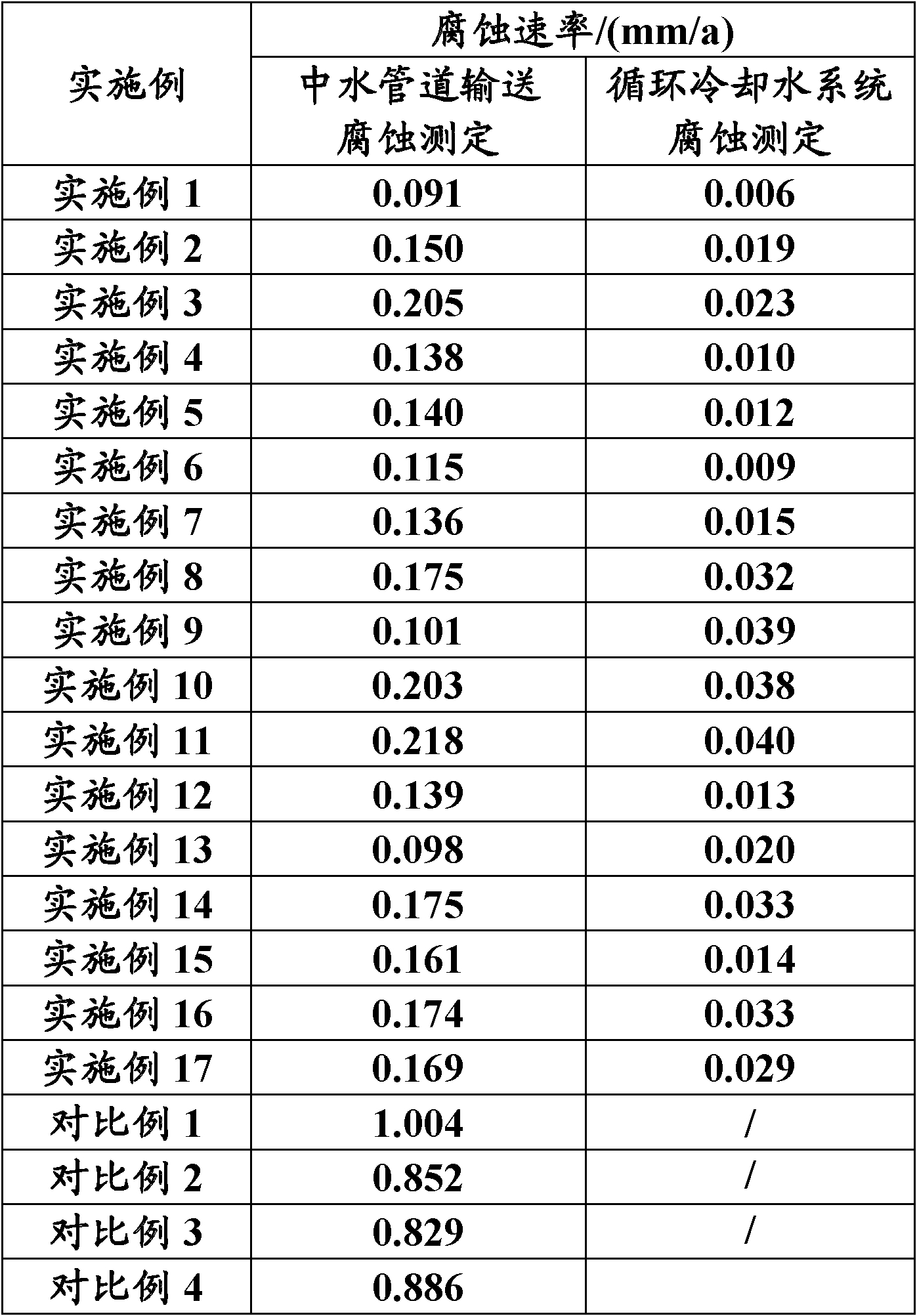

[0018] Potassium dihydrogen phosphate and zinc sulfate heptahydrate were added to the raw water of reclaimed water, so that the concentrations of total phosphate and zinc salt in the water were 2.88mg / L and 0.85mg / L respectively, and the corrosion evaluation test of reclaimed water pipeline transportation was carried out. The above-mentioned medium water that has been added with potassium dihydrogen phosphate and zinc sulfate heptahydrate is concentrated 5 times under the condition of pH=7.5 ± 0.1, adds acrylic acid / hydroxypropyl acrylate copolymer (the quality of acrylic acid and hydroxypropyl acrylate in the copolymer The ratio is 4:1, and the limiting viscosity number at 30°C is 0.071dL / g)20mg / L, and the corrosion evaluation test of the circulating cooling water system is carried out in this way. The results of the two tests are shown in Table 2.

Embodiment 2

[0020] Add disodium hydrogen phosphate and zinc chloride to the raw water of reclaimed water, so that the concentrations of total phosphate and zinc salt in the water are 1.95mg / L and 0.43mg / L respectively, so as to carry out the corrosion evaluation test of reclaimed water pipeline transportation. Concentrate the above-mentioned medium water with disodium hydrogen phosphate and zinc chloride 4 times under the condition of pH=7.8±0.1, add acrylic acid / 2'-acrylamide-2-methylpropanesulfonic acid copolymer (in the copolymer The mass ratio of acrylic acid to 2'-acrylamide-2-methylpropanesulfonic acid is 5:1, and the limiting viscosity at 30°C is 0.068dL / g) 12mg / L, and the corrosion evaluation test of the circulating cooling water system is carried out with this . The results of the two tests are shown in Table 2.

Embodiment 3

[0022] Sodium phosphate and zinc chloride are added to the raw water of reclaimed water, so that the total phosphate and zinc salt concentrations in the water are 1.37mg / L and 0.55mg / L respectively, and the corrosion evaluation test of reclaimed water pipeline transportation is carried out. Concentrate the above-mentioned reclaimed water with sodium phosphate and zinc chloride 5 times under the condition of pH=7.5±0.1, add acrylic acid / hydroxypropyl acrylate / 2'-acrylamide-2-methylpropanesulfonic acid copolymer ( The mass ratio of acrylic acid, hydroxypropyl acrylate and 2'-acrylamide-2-methylpropanesulfonic acid in the copolymer is 7:2:1, and the limiting viscosity number at 30°C is 0.087dL / g) 14mg / L, In this way, the corrosion evaluation test of the circulating cooling water system was carried out. The results of the two tests are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap